When mounting pipeline structures, various fasteners for pipelines are used, which include brackets, straps, clamps, etc. The fixing option and the type of fixing device are chosen based on the technical characteristics of the communication (for example, manufacturing material or weight). Buying the right fittings not only facilitates installation, but also extends the life of the system as a whole.

Mounting Requirements

The assortment of shaped products is incredibly wide - if you wish, you can choose a part for any type of custom designs. There is even a grounding clamp for pipes, which perform two functions - fixing the pipes and grounding the structure. All fasteners are divided into types according to their technical characteristics. Regardless of which particular shaped elements are used, they should have the following qualities:

- reliability;

- reusability of use;

- universality;

- resistance to corrosion;

- resistance to mechanical damage;

- durability;

- ease of installation.

Important! A very important point is the availability of the part. The most popular options for fasteners can be found in any hardware store and, conversely, some devices are rarer or made to order.

If the structure is a supporting structure, then the requirements for fastening devices are multiplied. In this case, pay attention to the material from which the pipeline is made.

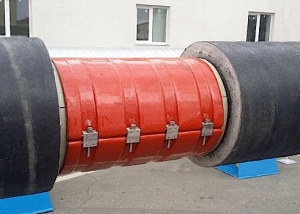

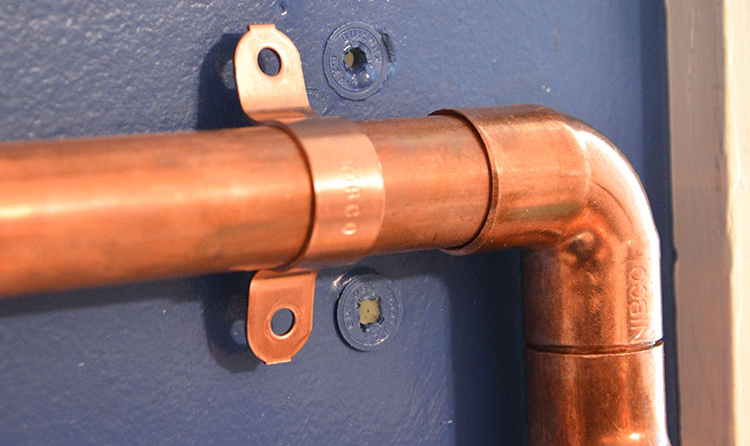

When choosing fasteners, you should pay attention to the material from which the pipes are made, for example, copper clamps are needed for copper water supply

If the line is made of plastic, then its installation on fasteners differs in a number of features:

- polymeric materials are predisposed to linear expansion, so they can increase their length in straight sections. This feature should be considered when choosing brackets and other elements. They should not impede the movement of communication and have a special locking structure;

- plastic pipes are not as strong as metal pipes, so for their installation you need to choose smooth parts, without sharp edges that can not cause damage to the polymer pipeline;

- metal clamps with a screw for fixing pipelines and repairing them are ideally suited for metal communications, and for plastic pipelines flat devices with smooth edges are an ideal solution;

- strength indicators of polymer pipelines are significantly inferior to metal analogues, therefore their use as load-bearing structures is impractical;

- plastic pipes are not fixed with clamps on static supports - this can lead to damage.

Fastener Classification

All types of pipe mounts are classified according to two main indicators:

- method of use;

- mounting method.

The method of using fasteners is chosen, focusing on their design characteristics. The following device options are distinguished:

Movable. Such elements are used in cases where it is necessary to maintain the mobility of the pipe. Pipe movement results from exposure to high temperatures. These parts are very popular when installing plastic communications and laying in underground channels.

Motionless. Fasteners that are vibration resistant and also able to damp linear expansion in the system.

Sliding. Such fasteners allow pipes to move not only in the longitudinal, but also in the transverse direction.

Suspensions in piping structures play a very important role, since thanks to them there is a uniform load distribution in the system. They are used in order to avoid overloading certain parts of the water supply system and to fix the structure on a wall, floor or other surface.

According to the installation method, the following categories of fasteners are distinguished:

- unpackaged;

- welded case type;

- case (clamp type);

- shield.

An open-loop clamp is a standard option, and body clamps are combined with a pipe by welding.

Varieties and characteristics of mounts

The most common types of fasteners for various pipeline communications are:

- brackets;

- strips;

- clamps.

Brackets are a special cantilever part that is used to fasten pipeline structures to vertical or horizontal surfaces. Depending on the design, these types of these devices are distinguished:

- simple (consisting of one part);

- complex (consisting of several elements).

Helpful information! Such mounts are used to install communications with a diameter above the average. In addition, the brackets are often combined with other fasteners (pendants, clamps, etc.).

The mounting plate is a product that has become very popular in the installation of underfloor heating. Such a device consists of a plate and special clamps in which the pipes are installed, the bar itself is fixed on a certain surface.

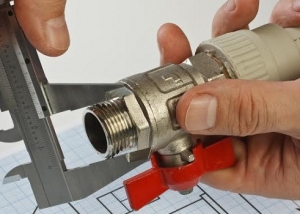

Clamps - devices for repair and fixation of pipelines. There is such a detail as a grounding clamp for pipes - it performs several functions at the same time. Such devices are divided into types of material:

- metal;

- plastic.

Metal products are more durable, so they are used for fastening heavy pipes (copper, cast iron, steel). The metal clamp with a screw is quite durable and easy to install. The design of such a device includes a special gasket for tight and tight grip with the pipe.

Plastic clamps, although they are less durable, however, are used much more often. This is due to the fact that today polymer pipes occupy a leading position in the market.

On the use of clamps are:

- pipe (equipped with a nut).

- hose (also equipped with a nut)

- reinforced.

- electrical engineering.

- one-piece.

- repair.

Plumbing clamps are used for pipe repair, and fasteners - for fixing not too massive communications.

The grounding clamp for pipes performs two functions - fixing and grounding of the pipeline. The design of such products is represented by a flat hoop and a rod that is inserted into the pipe cavity. The grounding clamp for pipes, as a rule, is mounted by welding for tightness and structural strength. There is also a grounding clamp for grounding pipes - it is pulled together with a special screw that is included in the kit.Such clamps are very popular products - their assortment today is quite wide.