A fan riser (aka air) is a very important element in the arrangement of a country house. It is a special pipe that connects the sewer system with open air. If there is no fan riser, then a vacuum may occur in the sewer, which will lead to a violation of the water seal. This leads to the penetration of sewage gases into the room.

The fan riser is an important component of the sewer system of the house, responsible for the ventilation of the drainage network

Content

Why is a fan pipe necessary and in what cases should it be installed

All plumbing devices must be equipped with an outlet pipe with a bend. In this knee is located water, which is a water lock and prevents the entry of unpleasant odors from the sewer into the house. Disruption of a water seal can occur when a large amount of water is abruptly discharged into the system and a vacuum occurs in it.

The fan riser has a stabilizing function. If there is a vacuum in the system, air from the street enters through such a pipe. As a result of this, pressure equalization occurs and the possibility of violation of hydraulic locks in plumbing devices is excluded.

Helpful information! In some cases, you can do without installing a fan riser. For example, if the building has 1-2 floors and is equipped with only one plumbing unit. Otherwise, the installation of such a design is a necessity.

Consider the options when installing such a riser is necessary:

- a building consisting of two or more floors, each of which has a plumbing unit;

- in the event that the sewer has a cross section of 50 mm;

- if there is a pool or any other object that discharges a huge mass of water;

- if the house has a sealed sewer, which uses a septic tank.

All of the above cases requires the mandatory installation of a sewage system, otherwise there is a risk of an emergency. Sewer gases not only have an unpleasant odor, but are also poisonous, contain harmful fungi and spores, and can be harmful to human health.

Requirements for Fan Stands

The installation of this equipment requires the necessary calculations and does not tolerate deviations from them. A fan riser has a very important function, so you need to approach its installation with all seriousness. When installing an air riser, several important points must be considered:

- equipping a pipe on the roof, it is worth remembering that the height of the external fan pipe for sewage above the roof material should be at least 30 cm;

- if the house has an attic or attic, then the height of the pipe above the roof should be at least 3 m;

- the distance between such a structure and a light opening or a loggia should be at least 4 m;

- installation of such a design should be carried out through heated rooms.If the pipe passes through unheated rooms, it is recommended to equip it with special heat-insulating material;

- categorically forbidden to remove the fan pipe through the chimney;

- At the end of the pipe, it is necessary to install protective devices (caps and grilles) that will protect the structure from atmospheric precipitation, as well as debris and birds.

Many owners are interested in the answer to the question: is it possible to output a fan pipe horizontally (through walls)? The horizontal arrangement, as a rule, is carried out if individual construction is carried out. And also if the house does not have enough ventilation shafts for vertical installation of the structure. It is worth noting that if the pipe is led out through the wall, its end is closed with a protective grill, and not with a tip.

Design

To perform the correct installation of this duct, first of all, it is necessary to take care of the design of the project. Such a project must meet two requirements that must be considered in all cases, without exception:

- the installation of the pipe is carried out in the direction of the drain of sewer gases using wind power;

- the pipe for the ventilation riser should have a cross-sectional index no greater than that of the sewer riser.

Installation of a fan riser is a necessary measure in most cases and is carried out by supplying a pipe to the ventilation duct. In some cases, such installation is not possible and the outlet is made through the wall.

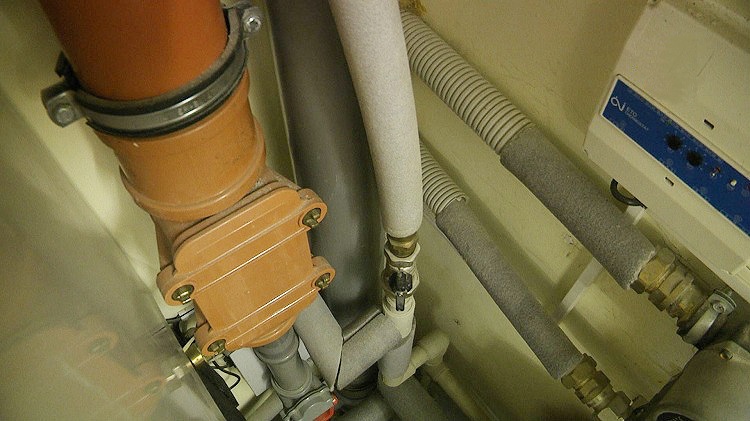

The system by which the sewage vapor is removed includes the following structural elements:

- fan pipes;

- docking pipes;

- ventilation ducts;

- connecting elements (fittings).

Preparing for the installation of the fan trunk

For the arrangement of such a design, the same structural elements will be needed as for the installation of a drainage communication. Depending on the specific case, it is necessary to calculate the amount of materials and prepare them in advance.

As a rule, pipes and connectors made of plastic are used for installation. This is due to the fact that the installation of such elements is much easier than metal and, in addition, they cost an order of magnitude cheaper. Old highways made of cast iron quite often fail. There is an opinion that replacing a metal structure with a plastic one is unacceptable, however, this is nothing more than a myth.

Important! In no case should you replace parts of the old cast-iron construction with plastic ones. The combination of materials can cause many problems, so you need to completely change the entire structure.

In addition, experts recommend choosing homogeneous materials both for arranging fan ventilation and for a wastewater system. For a cast-iron system, ventilation from the same material is selected. When combining materials, it is recommended to consult a specialist who will help you calculate the possible risks associated with this installation option.

Consider the list of parts that will be required when installing a fan riser:

- pipes with bends;

- special rubber seals, which are necessary for reliable connection of individual structural elements and good sealing;

- transition elements;

- clamps (for fixing the riser to the walls).

If you first need to dismantle the old communication, then in this case the following tools will be required:

- sledgehammer;

- drill;

- Bulgarian.

The installation site also needs to be prepared, having cleared it of all unnecessary.And also it is worth remembering that there should not be fire hazardous materials near the installation site of the fan riser. During installation, it is strictly forbidden to use the sewer system. If you have neighbors, then they must be warned that work will be done to replace the fan riser.

Installation of a fan riser

The fan riser is mounted from the lowest sewer communication or from the base. The second option is relevant for private homes. Pipe installation is best done in a straight vertical line, however, in some cases, you can not do without lateral fan branches. In these cases, special fittings are used:

- fan tee;

- crosspiece;

- audit.

When installing a fan riser in each restroom, a large-sized tee is installed, which fits into the toilet pipe. In addition, there is one important rule - the design must have as many tees as there are sections of volumetric wastewater discharge. Installing a separate fan tee in the bathroom is not required. Also, each such system, without exception, is equipped with crosspieces of fan pipes. The crosspiece fits into the downpipes of sinks, bathtubs and various equipment (washing and dishwashers).

After installing the fittings and docking the central fan riser with the side pipes, it is necessary to connect it to the external sewer communication. Sewer communication is connected to the central fan pipe using a special fitting - revision.

Outlets of fan ventilation are joined with outlets of plumbing equipment and securely fixed. In order to achieve the necessary tightness indicators when docking fan ventilation with a riser, it is recommended to use special rubber seals. Experts recommend installing seals using silicone. As a result of this installation, really reliable connections are obtained.

Note! To fix the clamps in the wall, holes must be made. It is advisable to choose steel clamps. This is due to the fact that they are very strong and reliable products and are able to provide good fixation of the fan riser.

An important point is the arrangement of sound insulation. Not every person is pleased to listen to the sounds that are formed when transporting wastewater through a sewer riser. For such purposes, construction foam is excellent. You just need to apply foam to the pipe and let it harden. The result is good sound insulation, however, this method has some disadvantages: unaesthetic appearance and the difficulty of servicing the sewer line.

When arranging a complex system that includes branches, it is recommended to use special mineral slabs or rock wool as soundproofing material. In addition, there is another way to arrange noise isolation - a special box. Such boxes have windows in order to carry out control and, if necessary, carry out repairs of the highway.

Vacuum valves instead of fan pipes

Most often, the fan pipe is equipped with a roof outlet. However, in some cases, the installation of a fan riser is carried out without ventilation through the roof. This may be due to various factors. In this case, you will need to install a special element that will perform the function of stabilizing the pressure in the sewer system - a fan valve for sewage.

A check valve for sewage is a device that has openings. Special sealing elements are placed in the holes, which prevent the penetration of air.

The principle of operation of the fan valve is quite simple: when the pressure drops in the communication, the springs that control the position of the sealing element are compressed and open the holes. Air enters through the holes, thereby equalizing the pressure in the system. When the pressure reaches the required value, the springs return the sealing elements to the opposite position. Some experts recommend using such a valve instead of a fan pipe.

The fan valve performs several other important functions:

- prevents the entry of foreign elements into the system;

- in the closed position it does not allow rodents to enter the house through plumbing fixtures;

- controls the movement of wastewater and does not allow them to move towards plumbing equipment.

Installation of the valve on the sewer pipe is carried out in two possible ways:

- directly into the pipe;

- on the surface of the pipe.

Before mounting this tool, it is recommended that the pipe be cleaned of dirt and grease.

Helpful information! There is a special arrow on the valve that indicates how to install it. Installation is carried out towards the movement of drains.

Petals fixtures should open towards the plumbing equipment. After mounting the check valve, no ventilation is needed.