The need for heating pipes of the sewer system arises when it is impossible to lay them below the depth of freezing of the soil. In addition, there are often situations that force owners of country houses to lay these utilities directly on the surface of the earth. In any case, to protect them from freezing, in addition to thermal insulation layer, additional heating elements should be used.

Content

Types of pipes to be heated and means for its implementation

The following elements of the domestic wastewater disposal system must be heated:

- external sewer pipes that discharge drains to a treatment plant or to a septic tank;

- pipes that connect the septic tank to drainage fields or a filtration well;

- pipes draining the wash water of the filter.

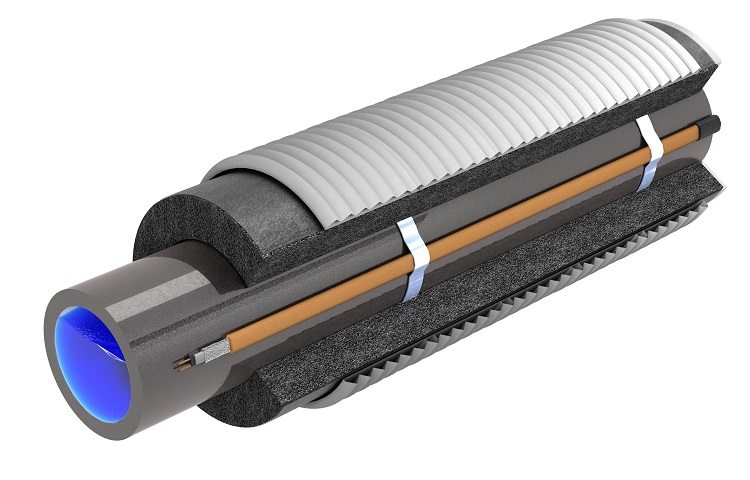

Traditionally, insulation is carried out by enveloping them with a thermally insulating material, creating an air gap and other methods. But modern technology offers a very convenient tool in the form of a cable for heating sewer pipes from the outside or from the inside. In addition, the industry today produces engineering communications elements, originally equipped with a heating and thermal insulation system. This refers to sandwich pipes, which are based on a plastic hollow product and a self-heating cable.

Of course, conducting electric heating of a household waste disposal system cannot be called a cheap event. But due to the fact that the sewage system at home will work reliably even in the most severe frosts, the costs will fully pay off. After all, it is possible that without heating the pipe can crack easily, and considerable money will be required to replace it.

The most commonly used sandwich pipes, in which a heating cable passes between the pipe wall and its upper coating

Outdoor heating systems

It should be noted that today the film method of heating sewer pipes is also very popular. The reason for this is the ease of installation and the reasonable cost of such a system. The main material here is a heat-emitting film.

Advice! When installing such a system, simply wrap the sewer pipes with film and fix it with tape or clamps.

But the organization of heating with a heating cable for sewer pipes is gradually gaining an increasingly large niche in this segment of the construction market. This option involves laying a cable along a heated pipeline. After the system is turned on, it will ensure that the pipes are heated to a predetermined temperature.

Modern industry produces the following types of heating cable:

- self-regulating. According to experts, the implementation of heating sewer pipes with a heating cable of this type is the most economical and, accordingly, the most promising. Such a product is able to "adapt" to weather conditions. When the outdoor temperature rises, the resistance of the self-regulating cable increases, which leads to a decrease in the current value.And if we consider the formula P = UxI, where P is the power; U is the voltage; I is the current strength, it will become clear that the power consumption in this case will decrease. And this leads to a reduction in energy costs. Moreover, in different parts of the insulated pipe, the heating power may differ in one direction or another. Given the constant increase in tariffs, this factor is very relevant;

- resistive. A characteristic feature of this product is the invariance of ohmic resistance, which is why the same amount of heat is generated along its entire length;

- zonal. The principle of its operation is the same as that of a resistive cable. But heat is only produced in individual areas. This property allows such a product to be cut and redistributed.

In fact, all cables act in the same way, but the features of one or another make it more convenient to mount and operate.

Resistive cables come in two types:

- single-core cable. Its only conductive core, which acts as a heating element, is covered with a layer of insulation, on top of which is a shielding braid, and then the outer shell. It is necessary to lay such a cable with a loop, since the connection to electricity is made from both ends, that is, they must converge in one place. Installation of a single-core resistive heating cable inside the sewer pipe is impossible because the overlapping of its segments on one another is not ruled out, because of which the cable can overheat and fail;

- two-core cable. One core serves only for the supply of electricity, and the other, which has a large resistance, acts as a heating element. Thus, to connect to the mains, it is not necessary to bring both ends of the cable to one place: for this there is a reverse conductor.

Pick up cable needed depending on the type of sewage system and the conditions in which it works.

Internal heating systems

This heating method has the following disadvantages:

- the reliability of the sewer pipeline is reduced due to the introduction of a tee;

- pipe clearance is reduced;

- the likelihood of clogging increases;

- if the pipeline has a considerable length, and is also mounted with numerous bends and transitions, laying a heating cable for sewage inside the pipe is difficult and time-consuming.

However, especially when the sewage disposal system is characterized by a large diameter, many owners of private houses prefer this type of heating.

They are usually used in small sections of the sewage pipeline. Most often, outdoor pumps act as objects for installing an internal heating system. The principle of its operation is identical to the principle of functioning of the external system.

Important! A significant difference is the need for pre-installation of a tee, through which, in fact, the heating cable is drawn inside the sewer pipe.

Interior Mounting

It should be noted that in many cases, the method of heating sewer pipes from the inside is the only possible solution. We are talking about waste water drainage systems made of polymer (PVC), asbestos-cement or concrete pipes, characterized by low heat conductivity. This property prevents the full heating of sewage through their walls. Install the cable inside the pipe, both over its entire length, and pointwise. In the latter case, most often this is the passage of engineering communication through the foundation.

The cable significantly increases the risk of clogging and during operation is constantly exposed to the negative effects of wastewater inside the pipe. In view of this, in order for it to serve for many years, it is necessary to approach the cable installation process responsibly and seriously.

If asbestos-cement pipes are used for sewage, then they will have to be heated only with an internal cable

In addition, so that the operation of heated sewer pipes does not cause additional optional problems, when laying the cable inside these utilities, the electrical wiring must be performed in the following sequence:

- clean and dry the pipes;

- remove the braid and sheath from the ends of the cable. It will be enough 5 cm;

- divide and clean the wires themselves by 4 cm;

- put heat-shrink tubing on the ends of the heating cables;

- heat the tubes with a building hair dryer;

- strip the ends 5-6 mm;

- place the braid in a metal tube inside the pipeline and secure;

- Clean and separate the ends of the power wires. The ground wire is 8 cm, while others are no more than 3.5 cm;

- connect the power wires to the heating cable using insulating tape;

- connect the metal braid and then insulate it too.

If you have at your disposal a large section of the pipe, but no revision or tee, it is recommended to cut a fragment of it, and then increase it using the compensating branch pipe of the corresponding adapter. To enter the cable into the sewer pipe, a special nipple sleeve is used. It is necessary to fix this element on the plug, and if there is still a revision, then on its cover.

Helpful information! When connecting a self-regulating cable, the power consumption in the first minute ˗ one and a half times exceeds the passport value by 3-5 times. But then this figure decreases.

Without the organization of high-quality heating of sewer pipes from the inside or outside, you run the risk of reducing the efficiency of the drainage system in the cold season. And the fact that cable heating consumes electricity cannot serve as a counterargument for the relevance of its use. After all, you can order a kit that will include not only a heating cable for sewage, but also thermostats and controllers. Using these accessories, you can track temperature fluctuations inside the pipeline and adjust the energy consumption.