As a rule, all utilities are laid outside the country cottage in the ground. Therefore, in severe frosts, they can simply freeze. To prevent this phenomenon, pipes must be insulated. Otherwise, a private house will not provide an acceptable level of comfort and convenience for its inhabitants. This seemingly difficult task can be solved independently.

Content

Insulation of the sewer pipe in the ground: methods

Those pipe segments that go outside the house and are located in close proximity to the surface of the earth are at particular risk of freezing. This factor should be taken into account at the stage of building construction. But to lay pipes below the freezing depth of the soil is very difficult if the value of this parameter exceeds one meter, and also if there is a high level of groundwater. In this case, one cannot do without more expensive methods of warming a sewer pipe in a private house. These include:

- the use of insulating foam shells;

- insulation of external sewage pipes using heating electric cables;

- the use of heat-insulating structures of various types;

- combined options.

When choosing a method of warming sewer pipes of external sewage, it is necessary to take into account the climatic zone in which the house is located and the method of laying the pipeline.

Climate zone

Insulating pipes in the southern regions of our country is not necessary. It’s enough to just lay them underground on calculated depthThen fill the pipeline with soil. Often it is wrapped with a thin insulation. But, as practice shows, such isolation is an extra waste of money.

In the northern regions, the heat-insulating structure must necessarily include a thick layer of insulation (at least 10 cm) and a protective box.

Helpful advice! Before insulating the sewer pipe in the ground, do not be lazy and study as many types of thermal insulation materials as possible. In today's market you can find those that are able to cope with low temperatures with a smaller thickness. And this is a saving of forces and material resources.

Pipeline method

When the pipeline is laid in the ground, its thermal insulation is carried out by filling the trench with expanded clay, asphalt, or other material similar in properties.

Roll or plate types of thermal insulation are often used. But in the latter case, it will be necessary to create external protection for them. It can be implemented by creating a box of concrete blocks or bricks, which must be waterproofed. Only then, in winterized sewerage pipes, ice plugs from sewage will not form, which will save the owner of a private house from unnecessary unnecessary expenses.

Choose a heater

Outdoor insulation a sewer pipe with correctly selected heat-insulating material is the key to reliability and cost savings. The assortment in this segment of the domestic market is so wide that it is sometimes difficult to make a choice. However, it is worth listening to the opinion of experts. They recommend purchasing only such insulation that does not need additional waterproofing.

Styrofoam. This material consists of granules sintered to each other up to 50 microns in size. The shell made of polystyrene foam is a hollow cylinder cut in diameter. The simplicity of arranging thermal insulation is one of its advantages. Even for those who do not know how to insulate the sewer pipe, it will be possible to do this on their own. Before laying in the ground, the shell must simply be put on a segment of the pipeline, and then fasten the halves with construction tape or clamps.

Other advantages of this thermal insulation material include:

- ecological cleanliness;

- long term of operation;

- ease of dismantling in case of need for repair work;

- low cost.

Extruded polystyrene foam (penoplex). This foam material also consists of granules. For those who are looking for an answer to the question of how to insulate a sewer pipe in the ground, penoplex will be the best choice.

This is due to many factors:

- Firstly, this material withstands large mechanical loads.

- Secondly, it can be operated at high humidity.

- Thirdly, a long - at least 50 years (!) - service life.

In addition, extruded polystyrene foam is characterized by high rigidity. Due to this property, it is also used for insulation of the blind area, basements and the foundation of a private house.

Technological mineral cotton wool. This material is divided into the following types:

- Glass wool. Glass is used as a raw material for its manufacture. Insulation of glass-wool sewer pipes is most widespread due to its low cost, low heat conductivity and increased resistance to vibration loads.

- Basalt wool. Insulation made from basalt wool is more versatile than glass wool, or with other products similar in functionality. This is due to the fact that, based on basalt fibers, modern industry can produce materials with different strength indicators. This allows you to give the heater a different shape without compromising the integrity of its design.

Basalt wool is available in the form of cylinders and rolls. Many of our compatriots may quite reasonably have a question: how to insulate sewer pipes using this material at minimal cost.

Helpful advice! Experts recommend giving preference to cylindrical products. Sewer pipe insulation using an inexpensive coil of basalt insulation will require financial costs for additional waterproofing pipes.

- Slaggy. For the manufacture of this material blast furnace slag is used - one of the waste products of the iron smelting process in blast furnaces. The disadvantages of slagging include its ability to quickly absorb water. For this reason, for the insulation of pipelines laid in the ground, including sewer pipes, it must be protected with a layer of waterproofing.

Foiled isolon. This material is widely used due to its resistance to moisture and bacteria, increased strength, ease of installation and long service life - more than 50 years.Special knowledge on how to insulate the sewer pipe on the street with the help of foil insulator is not required. The roll is simply cut into narrow strips and wound on a pipe in a spiral. Fixing is carried out using plastic clamps, electrical tape or tape.

PND ˗ polyethylene low pressure. Pipelines made of this material are ductile. In addition, HDPE is characterized by low thermal conductivity. Due to the combination of these properties, the material itself can serve as a heat insulator of engineering communications on the street. And even if ice does form, the pipe will not break, but slightly deformed. With the onset of the warm season, the design will take on its original form.

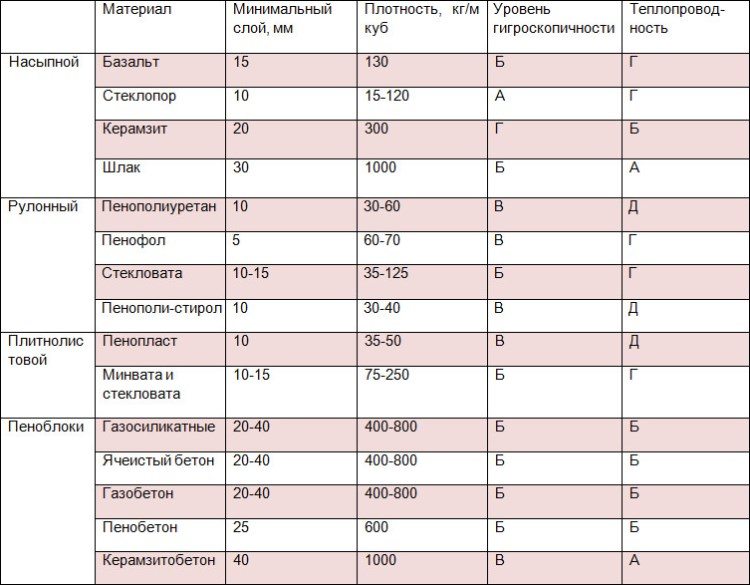

Comparative characteristics of thermal insulation materials

In addition to the above, modern industry produces other types of insulation of sewer pipes of a private house. You will learn their heat-insulating properties by examining the table below.

In the table, letters indicate the hygroscopicity and thermal conductivity class from the highest level (“A”) to very low (“D”).

Warming sewer pipes in the ground with an electric cable

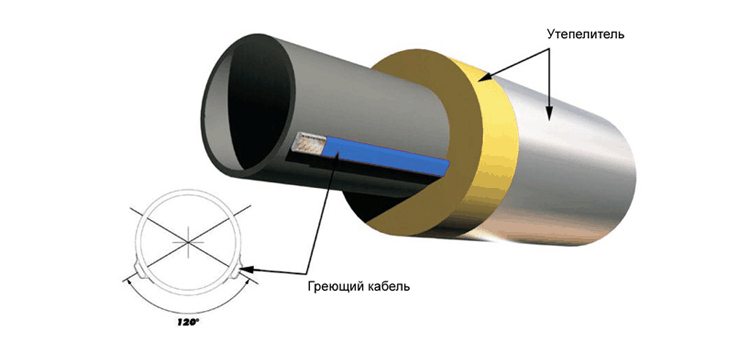

According to experts, this is the most effective way to prevent the failure of the external pipeline sewers for those regions where in the winter on the street the temperature often drops below -15 ° C. Installation of the heating system is quite simple: cable hardens over the pipe or passes inside it. It is connected to the network through a circuit breaker and a residual current device.

To achieve the desired effect, the cable can be laid outside with one or several threads, in a spiral or a wavy line. The electric cable is fixed using aluminum tape. The whole structure must be covered with a layer of thermal insulation, especially if it will be laid in the ground.

Helpful advice! If the outer sewer pipe is not made of metal, but of plastic, glue it with aluminum foil before installing the cable. Then the heat will spread evenly over the entire surface of the pipe.

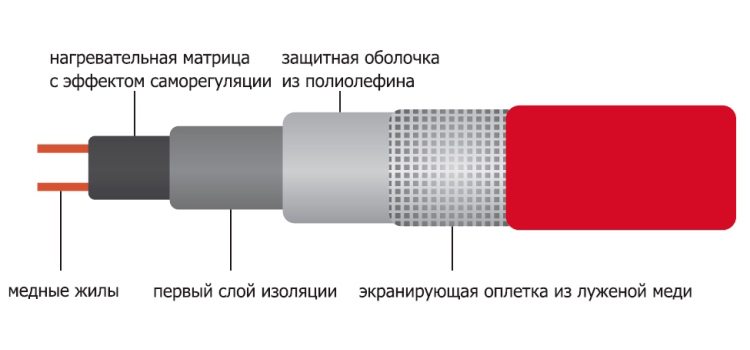

Today, there are two types of heating electric cables on the market: ordinary (resistive) and self-regulating. Although the first option is cheaper, its operation causes high energy consumption. Therefore, even knowing how to insulate the sewerage in a private house with the help of a resistive heating cable, one should think about whether the bills submitted for payment will put a heavy burden on the family budget.

On this background self-regulating cable compares favorably with a significantly lower level of electricity consumption. It heats only those sections of the pipeline whose temperature has become less than a certain minimum value. After this parameter returns to the operating range, a specific cable segment will cease to consume electricity.

We warm pipes reliably

The combination of various heat-insulating structures is the best option on how to insulate sewer pipes in a private house. For example, many far-sighted owners of suburban cottages not only lay sewer pipes in the ground below the freezing depth of the soil, but also lay insulation around these utilities. After all, winter is not necessary for winter. Therefore, the earth may freeze below this mark.

Of course, such insulation will cost not cheap, but it’s better to overpay when arranging the system than to spend much more money on repairing it later, while living in uncomfortable conditions. In any case, the owner of the private house remains the choice.