Recently, plastic pipes have been replacing pig-iron pipes at a rapid pace. Now you will not be surprised at any newcomer by the fact that in the bathroom, toilet and in the kitchen, the domestic sewage system is based on polymer products. But this segment of the building materials market is subject to change. So, if until recently the products of polyvinyl chloride were the undisputed leader, today polypropylene pipes for sewage occupy a niche of comparable size.

Content

Advantages of polypropylene sewer pipes

These products are produced by hot extrusion, where stabilized light gray polypropylene acts as a raw material. The advantages of a drainage system created on their basis are:

- Light weight.

- Smooth surface. Due to this, debris does not linger in the cavity of the pipe.

- No corrosion.

- Excellent hydraulic properties.

- Resistance to significant temperature differences. Polypropylene pipes will begin to melt when the value of this parameter exceeds + 175 ° C, and soften at + 140 ° C.

- Increased wear resistance. Therefore, these products are recommended for organizing a drainage system with a large number of abrasive solids.

- Relatively low cost.

Such pipes are easy to install and easy to maintain. Most species tolerate aggressive use. cleaning products.

Classification and Application

Sewer polypropylene pipe is marked with the following sequence of characters: PNxx, where instead of “xx” there can be numbers 10, 16, 20 and 25. They correspond to the maximum permissible pressure in kg / cm2.

- PN25 - reinforced pipes. The presence of fiberglass or aluminum foil additives in polypropylene gives these products the following characteristics: low coefficient of thermal expansion and high strength. Such polypropylene pipes are used for external sewage;

- PN20 - pipes of increased impact strength. In addition to internal sewage, products of this category are widely used in the organization of ventilation systems, water supply systems and floor heating systems;

- PN16 ˗ pipes for gravity drainage. According to the calculations, their service life reaches 220 (!) Years at a temperature of the working environment + 40˚С;

- PN10 обычной pipe of ordinary strength. The spectrum of their application is the widest. Due to the optimal value for the price / quality ratio, buyers prefer PN10 pipes. They are suitable for creating an internal sewer system, underfloor heating (at a nominal operating pressure of 1 MPa and a temperature of up to 45 ° C), as well as a cold water supply system.

To give the final product the necessary characteristics - resistance to UV radiation or ring stiffness - use various copolymers of propylene, organic and mineral additives.

For example, foil reinforcement can prevent oxygen from entering the coolant and reduce thermal linear expansion.

To purchase sewer pipes that will last for many years under your operating conditions, pay attention to the composition of the raw materials. He, as well as his technical characteristics are indicated in the passport for the product.

Important! The use of reinforced pipes implies mandatory edge trimming so that there is no contact with the coolant.

Range of standard polypropylene pipes

The hot extrusion technology used for manufacturing involves the production of measuring segments with a clearly defined cross-sectional diameter. At the same time, manufacturers are entitled to determine the dimensions of the assortment of polypropylene pipes independently. However, they should be guided by industry documents. In particular, in TU 4926-002-88742502-00 it is written that the overall characteristics of polypropylene pipes for sewage should not go beyond the following size range:

- Pipe diameter. For a non-pressure drainage system, the value of this parameter can be equal to 150, 110 and 50 mm. The greatest demand is noted for products with a diameter of 110 and 50 mm.

- Pipe length. The range of changes is as follows: minimum ˗ 2, maximum - 8 meters. Between adjacent dimensions, a meter sampling step must be observed. It should be noted that it is allowed to produce products with a length of 12 meters.

The range of pressure sewer pipes looks more impressive. Their diameter ranges from 32 ... 1600 millimeters, while the length can be more than 12 meters. This is due to the fact that pipes are produced in bays. Thus, if you are satisfied with the standard sizes, choose from a limited assortment of pressureless pipes.

If there is a need for products of a different length and a different diameter, stop your choice on pressure pipes. To purchase products with the maximum values of these parameters should be if you equip the external sewage system in a large country cottage.

Variety of sizes

Such a characteristic as wall thickness is an equally important indicator. Indeed, the inner diameter of the pipes directly depends on this parameter. The table below shows the variety of sizes of polypropylene pipes produced by modern industry.

| Outer diameter mm | Wall thickness PN25 with alum. foil, millimeters | Wall thickness PN20, millimeters | Wall thickness PN16, millimeters | Wall thickness PN10, millimeters |

| 16 | 2,7 | 2,7 | ˗˗˗ | ˗˗˗ |

| 20 | 3,4 | 3,4 | 2,8 | 1,9 |

| 25 | 4,2 | 4,2 | 3,5 | 2,3 |

| 32 | 5,4 | 5,4 | 4,4 | 3,0 |

| 40 | 6,7 | 6,7 | 5,5 | 3,7 |

| 50 | 8,4 | 8,4 | 6,9 | 4,6 |

| 63 | 10,5 | 10,5 | 8,4 | 5,8 |

| 75 | 12,5 | 12,5 | 10,3 | 6,9 |

| 90 | 15,00 | 15,00 | 12,3 | 8,2 |

| 110 | 18,4 | 18,4 | 15,1 | 10,00 |

Use of polypropylene pipes in outdoor sewers

External pipelines are subject to increased requirements because they work in difficult conditions. The pipe material must:

- Resist the negative effects of groundwater, which provoke the displacement of docking nodes. As a result, the system may be depressurized;

- be resistant to dynamic and static loads;

- withstand the weight of the backfill and the displacement of the soil from the movement of vehicles and people.

If pipes need to be laid deep or specific soil, use boxes from different materials. They lay pipes in them.

Polypropylene pipes are the best choice for arranging a free-flow "stormwater" system and an external sewage pipe system in a residential building.

Helpful advice! Polypropylene is sensitive to UV radiation. Therefore, with the open method of laying the sewer system, it is recommended that the surface of the pipes be closed from direct sunlight.

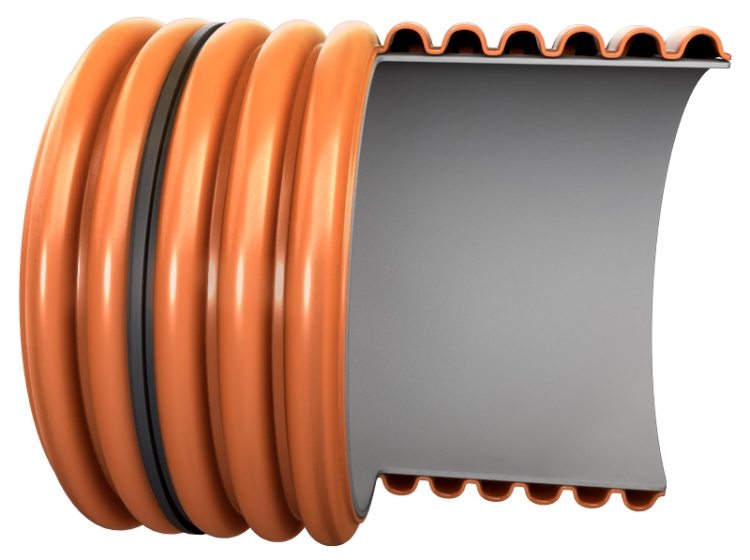

Double Layer Corrugated Polypropylene Sewer Pipe

To create an external sewage system, two-layer corrugated polypropylene pipes are especially in demand today.Their technical characteristics make it possible to transport effluents, the temperature of which reaches + 95 ° C, as well as aggressive liquid industrial waste.

In addition, the main advantages of two-layer corrugated pipes made of polypropylene include:

- high ring stiffness - from 10 kN / m2. This value corresponds to the stiffness class SN8;

- resistance to so-called stray currents and corrosion resistance. The combination of these properties distinguishes these products from cast iron and steel pipes;

- low roughness coefficient leads to increased resistance to waterjet wear;

- lack of overgrowing pipes Due to this, it is possible to lay such products with a minimum bias. The capacity of the external sewage system will still be at a high level;

- resistance to mechanical shock at low temperatures. At -20 ° C they withstand a pulsed load of up to 7 kJ / m2;

- high maintainability. The implementation of repair inserts, as well as interconnecting new sections of the pipeline allows the use of standard couplings.

Airtight docking polypropylene sewer pipes will provide not only the use of self-adhesive tapes and various sealants, but also welding. However, this will require a special tool and skills. In addition, this solution will cause problems with the dismantling of pipeline segments.