When laying a pipeline, home craftsmen, as a rule, are faced with the need to attach part of the system to a wall, floor or even ceiling. For this, it is important to use suitable elements and equipment. In this case, the type of material from which both the pipe and the surface of the intended fixation point are made should be taken into account. Most often, metal brackets are used to fasten steel pipelines.

Key Features and Selection Criteria

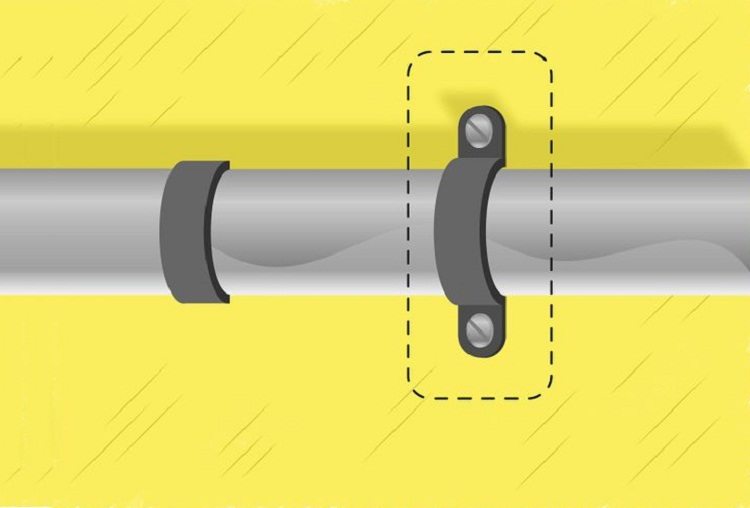

The bracket is one-leg or two-leg.

The metal bracket is single-foot. Such a part is intended for pipelines with a diameter within 10 ... 32 millimeters. The most optimal use of a single-foot staple for fastening pipes in systems with a large number of bends. Fixing to the wall, and even more so to the floor, turns out to be strong. This is ensured by the presence of a stiffening rib at the arch bend of the one-foot staple. Such a constructive solution allows the use of this fastener in other areas with increased requirements for the reliability of the design. For example, it is allowed to fasten electric cables and wires of telecommunication systems with a one-foot bracket.

The metal bracket is two-armed. This element is intended for pipelines with a diameter varying in the range of millimeters. Such a part is used, as a rule, when laying engineering communications branches outdoors. The fixing of a two-valve bracket for fastening pipes is carried out using screws or self-tapping screws.

It is necessary to choose any of these parts taking into account the following characteristics of a steel pipe:

- material of manufacture;

- destination;

- surface to which you plan to mount: vertical (to the wall) or horizontal (to the floor or ceiling);

- sizes.

As the starting material for the manufacture of such fasteners, not only steel sheet can be used, but also wire and even propylene material. However, in most cases, it is very difficult to find a replacement for metal steel brackets for fastening pipes.

Benefits

Products of both types - one-leg and two-leg - have many positive properties, of which the following can be distinguished:

- reasonable and optimal cost;

- universality. These products are used not only for a variety of pipelines, but also in many other spheres of human activity;

- significant mechanical stresses do not harm such products. Therefore, they are rightly considered reliable and durable;

- long service life.

Helpful information! Among other things, some models of metal brackets (for example, from the Italian brand Stilma) provide the ability to lay pipes at a certain distance from the walls. This is especially true for domestic gas supply lines.

According to consumer reviews, the U-shaped bolt bracket is especially popular. Details of this type are very in demand when the installation of pipelines is carried out on an industrial scale. However, they are also used at home.Install a U-shaped bolt-bracket for attaching the steel pipe to the wall or floor. One of the features of this type of fastener is the ability to use a sliding support.

Selection tips

The main recommendations of experts on how to choose the bracket for pipes are formulated as follows:

- Both the fixing element itself and the tools with which it is supposed to fasten the steel pipes should be produced by one company. Moreover! Tools of other manufacturers whose products do not correspond to the brand of the product are generally forbidden to be used, since they can render the bracket unusable.

- Before buying, it will be useful to study customer reviews about the quality of the products of the brand you like. In this case, take into account the specifics of the work. As a rule, photos are attached to reviews. Having studied them, you will not be at a loss in all the variety of nomenclature positions of such products.

- Do not refuse the help of specially trained consultants, since each work related to the fastening of steel pipes has its own distinctive features. A special approach is required depending on how the fixation is supposed to be done - to the wall or to the floor.

What else to know

Often on the market there is a product that does not meet the requirements of European regulatory documents. One of them sounds like this: on a metal fastener for steel pipes, a layer of anticorrosive coating should be present. But that's not all. Until the beginning of the 21st century, in the EU countries, the so-called yellow passivation of metal surfaces by substances containing hexavalent chromium was the traditional technology of corrosion protection. So: Directive of the Council of Europe and the European Parliament number 2002/95 / EU banned its use on the territory of the states of the European community. As scientific studies have shown, such a coating harms both the environment and human health. And, unfortunately, such a layer is present on previously released pipe fastening elements to various surfaces - a wall, floor or ceiling of a residential building. And unscrupulous domestic businessmen sell the remaining stocks at half the price.

Now, on such products, a coating layer “CHROME VI FREE” is applied. In the Russian translation, this name sounds like this: “Free from hexavalent chromium.” In addition to harmlessness to humans and the environment, this composition increases the operational characteristics of steel pipe fasteners, in particular, gives them higher corrosion resistance.

In conclusion, a few words about how not to make a mistake and not to get the wrong copy. The quality of steel pipe fastening can be checked visually: it should have a light silver color coating. In any other case, do not buy the goods.