When conducting plumbing work, the contractor often needs to cut pipe products into segments of a given length. It may seem that there is nothing special about this procedure. However, to perform it efficiently, you will need special equipment for cutting pipes, which is called a pipe cutter. Its use allows you to get neat smooth edges, which greatly facilitates subsequent work.

Content

Varieties

All pipe cutters manufactured by modern industry are divided into the following types:

- tool for working with thin-walled pipe products. If you need a pipe cutter for copper pipes, stop your choice on a device of this particular category. As a rule, these are pipe cutters of the cutting or roller type. The latter are the most durable and convenient, moreover, they are not very expensive;

- machine for cutting pipes with thick walls. Such a tool copes well not only with steel, but also with cast-iron pipe products. There are pipe cutters for metal pipes detachable, multi-roller or chain. The thing is quite powerful and expensive. To carry out one-time work, acquiring does not make sense;

- pipe cutter for pipes made of brittle material. Concrete or ceramic pipe products are considered such. In everyday life, it did not find wide application, but pipe cutters for working with similar pipe products are produced. In most cases, a chain type tool is used to cut brittle pipes.

When choosing the appropriate option, you should choose the universal model of such a device. According to home masters, this is a roller pipe cutter. It copes with copper and steel pipes with thin walls.

Design Features

There are five types of manual pipe cutters in design.

1. Pipe cutter. The predominant field of application is working with plastic pipes. This tool looks like a special steel clip with fixed rollers. The tube product is cut precisely by means of these parts. A pipe cutter for plastic pipes of this type is capable of processing products with a diameter of up to 100 millimeters. In this case, the cut is neat and perfectly even, and this is a guarantee of high-quality joining of pipeline segments.

2. Roller manual pipe cutter. For steel pipes, such a tool is the best option. By and large, it was developed specifically for these products. By the way, the pipe cutter for metal-plastic pipes belongs to the same type of device for cutting pipe products. It is all the same clip, including a set of cutting and guide rollers. Their number in this device does not exceed 3 pieces. When choosing such a pipe cutter, it should be understood that its ability to process thick-walled pipes depends on how many such parts it contains.

Note! The disadvantages of this tool include the fact that the cut is not very neat. Burrs may be present on it.

3. Chain pipe cutter. The design of such a pipe cutter includes pivoting levers, a tensioning mechanism and chains equipped with cutting rollers. Its principle of operation is quite simple: a chain drawn around a pipe by rotating levers crashes into metal.

4. The telescopic rotary pipe cutter. Used to perform work in hard to reach places. Such a tool is very expensive. Scope - pipe cutting in pits, wells, wells. Moreover, this operation is allowed even under water when the performer is at a certain distance. Such a pipe cutting machine has the following structural difference: a handle, the application of force to which causes the pipe cutter to move, is removable. In addition, using the same part, a cutting tool (interchangeable rollers act as such) cuts into the pipe body. Among the features of a telescopic rotary pipe cutter, it is worth highlighting its ability to process pipes with wall thicknesses up to 19 millimeters.

5. Pipe cutter equipped with ratchet mechanism. Such a device is popularly called scissors. In most cases it is used for cutting thin-walled polypropylene and metal-plastic pipes. The maximum that such scissors are capable of is cutting pipes with a cross section of up to 30 millimeters. True, some modern models of such a pipe cutter cope with pipe products of a larger diameter. But for professionals who have to perform more than a hundred cuts a day, it will be very tiring.

type of drive

With the independent performance of one-time work, a manual pipe cutting machine is also quite suitable. But if we are talking about professional activities related to the installation of sections of pipelines, then in this case it will not do without difficulties. Moreover, manual cutting of pipes involves considerable time costs, which can lead to monetary losses. The combination of these factors led to the fact that professionals work with driven pipe cutters. Experts identify three varieties of such a tool.

Professional electric pipe cutter. Got the most distribution. Moreover, often such a device is also preferred by home craftsmen when working with pipe products made of copper. Its high cost is leveled out by the increased productivity. No special efforts are required: just bring the electric pipe cutter for copper pipes to the workpiece and press the “START” button.

Good to know! Subject to the technology, using an electric pipe cutter, it is possible to process metal-plastic, purely polymer, for example, polypropylene, as well as pipeline elements made of other materials.

The pipe cutter is hydraulic. This energy-consuming and very powerful unit is in most cases used in production. In addition, modern industry produces hydraulic pipe cutters that can be transported in the trunk of a car and used at construction sites. The principle of operation of such a device is based on the laws of hydraulics. Under the influence of the force exerted on the handle by the performer, the piston is driven. The liquid pushed by it, in turn, drives the rollers with a greatly increased force.

The pneumatic pipe cutter. This is also a very powerful unit capable of processing pipes with a cross section of up to 1300 millimeters. This type of pipe cutter is universal, that is, it is suitable for working with metal-plastic, steel and concrete pipes.

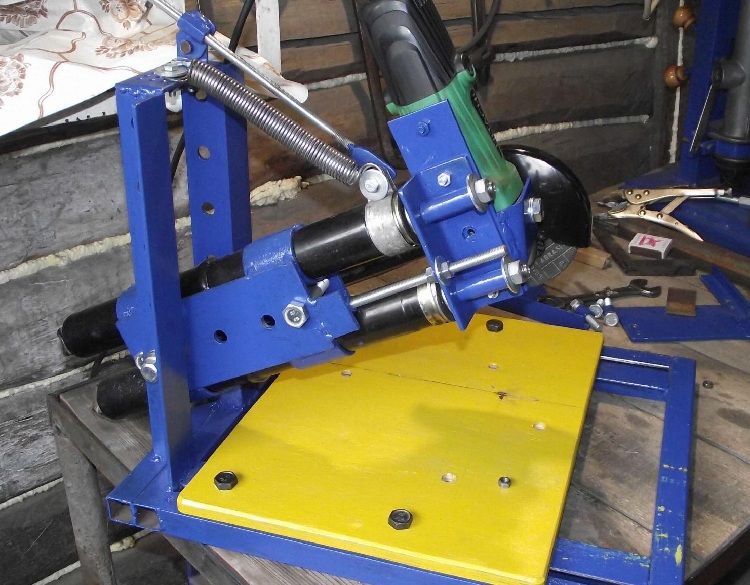

How to make a pipe cutter for stainless pipes with your own hands

Homemade pipe cutting tools are not a rarity. For their manufacture, craftsmen use improvised materials, which in vain occupy a place in the garage.And many adapt the grinder for this purpose, as a result of getting a kind of cutting machine. Below we will consider an example of creating the simplest pipe cutter for working with stainless steel pipes.

First of all, you need to make sure that the following tool is at hand:

- hammer;

- screwdriver;

- files and files;

- hacksaw for metal;

- yews;

- spanners.

In addition, to make a pipe cutter for stainless pipes you have to stock up on such materials;

- square wire rod 15 × 15 millimeters;

- steel tapes 15 × 4 mm;

- spring;

- hacksaw blades;

- M6 screws;

- M8 bolt.

It will also be necessary to prepare two metal rivets with a diameter of 4 millimeters.

Work begins with the preparation of the workplace and tool. Start the manufacturing process by conveniently placing everything you need.

DIY making the left side of the pipe cutter. First cut the wire rod segment 135 millimeters long. Fill the lower end of the workpiece with a radius, or remove the chamfers and use a file to round them. The next operation is drilling a hole with a diameter of 8.2 ... 8.5 mm under the clamping bolt. The hole should be at a distance of 90 millimeters to the straight end of the workpiece. Then place the blade on the top of the workpiece, slightly departing from the top edge, and then fasten with steel screws and rivets the steel tape serving as the pressure bar.

Good to know! In order for the pipe cutter for stainless pipes to work correctly, the teeth on both parts - left and right - should be oriented in one direction.

Drill a hole under the axis with a rounding for the axis. If you do not have the axis of the part suitable for the function, you can make it from a bar with a cross section of 8 millimeters.

Making the right side. This stage will require more time. The basis of the right side, made of wire rod, is characterized by a complex shape. On the part of the working sector, two sections are being formed in accordance with two requirements.

- Their length is 40 millimeters.

- The angle between the sections is 90-120 degrees. And with the horizontal they should form an angle of 30 degrees. In the projection, the picture looks like a house roof.

Loose the shank remaining under the handle. Just as on the left side, on the bent sections of the manufactured part, attach the canvas. Mark the center of the threaded hole in the wire rod on the left side. The clamping bolt will be screwed into it. Fasten opposite the hole in the left part, into which the axis will be inserted, a steel strip. Its length is selected in accordance with the condition that the distance from the nearest edge of the handle to the center of the axis is 30 millimeters.

Then you just have to assemble the pipe cutter for stainless pipes. First, a clamping bolt is inserted into the hole on the left side of the product and a spring is put on it. After that, the axis is put in place. Having done this, screw in the clamping bolt into the threaded hole, which is located on the right side of the device. This is the last operation.

As you can see, it is not so difficult to make a pipe cutter for stainless pipes and products from other metals. The main thing is attentiveness and a clear understanding of how the final product should look.