In settlements located far from the city, as a rule, centralized water supply is absent. For owners of private houses, the choice of water source is limited by two options: a well or a well. According to its operational characteristics, a well is more preferable. At the same time, as practice shows, it is best to perform casing drilling. This technology has been tested and does not present any difficulties for a specialist.

Content

Types of Casing

Modern industry produces the following types of pipes for casing:

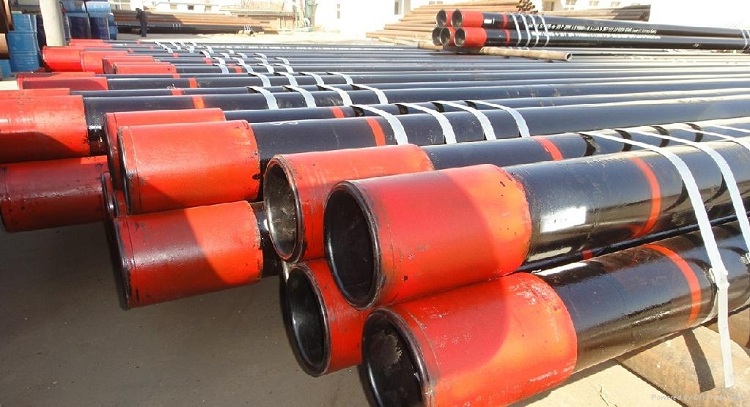

- metal. It is such products that have found the greatest application as casing pipes. Metal pipes ensure the safety of the water source due to the fact that they easily withstand small movements of the soil.

But you can not ignore one significant minus of steel casing - susceptibility to corrosion. As a result, already after a short period of time, flakes of rust from the inner surface will begin to fall into the water, because of which its quality is significantly reduced. There are two ways to deal with this phenomenon: the initial installation of stainless steel casing and the use of filters. But, since the cost of the stainless steel is rather big, such an option will cost the customer very expensive.

- asbestos cement. Pipe products from this material also have a number of advantages. For example, homeowners are attracted by a long service life at a low price of products. But asbestos-cement casing can be used only to a depth of 15 meters, since with a larger value of this parameter, the pressure exerted by the soil can cause the destruction of this fragile material. And the cost of work increases the need for drilling a channel with a large diameter due to the significant wall thickness of this type of pipe products. And also remember the dangers of asbestos to human health.

Good to know! Although asbestos is bound by cement, the risk of getting this material into drinking water increases over time.

- pipes made of plastic. As casing products from polyethylene and polyvinyl chloride are used. These polymers have inherent qualities that minimize (as much as possible) the level of labor during the installation of casing and reduce financial costs during the operation of the created water supply system.

If we compare plastic pipes with metal and asbestos-cement analogues, we can distinguish their such advantages:

- not susceptible to corrosion;

- the aging process of the material does not cause hazardous chemicals to enter the water;

- no calcareous deposits form on the walls of the polymer pipes;

- physical and chemical properties ensure a long service life;

- in comparison with other materials, the connection of plastic casing elements provides better tightness;

- the cost of polymer pipes is lower than this indicator for existing analogues.

Despite the popularity of polymer pipes, only steel casing strings are used for wells operating in difficult conditions.

Among the shortcomings of such pipe products, one can single out its inability to withstand heavy loads.Therefore, the technology of drilling with plastic casing is focused on creating a well up to 50 meters deep. The diameter of the tubular product is of great importance, and you need to choose it as accurately as possible, since the potential water flow rate, as well as the possible drilling depth, depend on it.

Casing technology

The basis of special equipment with which wells are drilled is a drill. It is its diameter that determines the cross section of the well being created, as well as casing pipe. Briefly, the casing technology itself can be described as follows: a drill is buried by a drilling rig. As it lowers, pipe elements are inserted into the drilled hole. They connect with each other on the surface. As a result, casing pipes protect the channel from destruction over the entire depth.

Sometimes solid fractions or even layers are encountered along the drill path. Then, water is supplied to the channel under pressure. She, softening the soil, allows you to continue drilling. Upon reaching a predetermined depth, casing pipes are mounted at the top. Another pipe is lowered into the channel. It is through it with the help of a pump that water will rise. To minimize the risk of trouble and ensure reliable operation of the pumping equipment, a filter should be installed to prevent sand and debris from entering the system.

Advice! It is better not to use water even when there is a filtering component in the well design immediately, but to drain a certain amount of it. And only after achieving transparency and maximum purity of the liquid, it can be used for domestic purposes.

And one moment. The larger the volume of the well at the very bottom, the more water will be available to the consumer. For this purpose, upon completion of construction, pump out fluid from the well for several days.

The casing pipe plays the role of the walls of the shaft, while water is supplied through another pipe, which falls into the casing

Upon completion of all these procedures, when the water becomes clean, it will be advisable to provide its sample in the SES. The specialists of this organization will conduct an analysis and issue a conclusion on the suitability / unsuitability of water for consumption.

Features of arrangement

After the casing of the well is completed, experts recommend pouring a small amount of clean river sand and granite or marble chips to the bottom. They will serve as an additional filter. Then the water will be of very good quality.

Why is it necessary to use hard rock crumbs and river sand. If ground sand or lime gravel is poured to the bottom of the source, the water will be contaminated with impurities that are invariably contained in these materials. They come out with the liquid for a very long time, and during this period it will be cloudy and unsuitable for food purposes.

Water comes with loud noises and interruptions or does not come from the source at all. These phenomena can occur for the following reasons:

- insufficient water level in the source;

- the filter is clogged or damaged;

- leak in the feed pipe;

- the check valve of the pumping equipment has failed.

The need to install the head on the casing. The main objective of this element is to prevent foreign objects from entering the channel mouth. In addition, an important factor is that the head protects equipment and components from theft.

In general, having established a similar design, the owner will solve issues of such a plan:

- the probability of freezing in the upper part of the well in winter will decrease;

- the source will be reliably sealed;

- well debit will increase;

- it will be possible to suspend the pump and reliably fasten the wiring.

The head is an important part of the well, it is a kind of cover that protects the entire structure from negative factors

Today, manufacturers are trying to fully satisfy the needs of the client by implementing additional opportunities for using the well head. The following options were most widely used:

- collet clamps and secret bolts to protect the structure from breaking;

- carabiners and eye bolts for hanging equipment;

- additional openings with spring guards against excesses for output of a power cable, etc.

Diameter selection

Currently developed the following methods of drilling wells:

- using a screw;

- core drilling;

- rotational shock method;

- Shock-rope method with casing.

Each of them is designed for the formation of wells, the diameter of which can vary within certain limits. For example, when drilling with a screw, the value of this parameter varies in the range 11≤Dsq.≤12.5 cm, and with core drilling 4.5≤Dsq.≤13 cm, where Dsq. - well diameter.

Good to know! The correct selection of the drilling method and numerical values of the parameters of all elements of the trunk, including its diameter, is carried out taking into account the tasks set based on the analysis of the features of the personal plot, as well as the characteristics of the existing power equipment.

Most brands of modern borehole pumps are available with a diameter of 74 millimeters (3 inches) and 100 millimeters (4 inches). For a three-inch pump, the pipe is selected according to the following principle: the thickness of the walls of the structure (for polyethylene casing it is 15 millimeters) and the gap between the pump itself and the pipe (usually 4 millimeters) are added to the diameter expressed in millimeters (in our case this is 74) . The result is a millimeter.

Thus, taking into account the standard range of manufactured, for example, steel casing, similar pipe products should be purchased with a diameter of 127 or 133 millimeters - these are the closest standard values.

The presented example is almost ideal in nature, since the actual size of the trunk, although not by much, but, nevertheless, may differ. This is due to the complex construction of the structure, the geometry of which depends on various factors. In particular, from the structure of the geological section on the site.

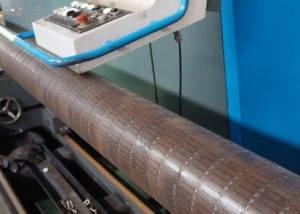

The length of the casing string links varies in the meter range, and when drilling, they begin to lower from a larger diameter. As the depth of the well increases, a transition to small sections is carried out. The links are connected to each other by screwing in the pipe-to-pipe method, with couplings or nipples.

Well Cleaning Tips

The need to perform this procedure arises for the following reasons:

- decrease in mirror level;

- deterioration in water composition;

- debit reduction.

The advice of professionals to combat these phenomena in a generalized form is as follows:

- in order to prevent abundant clogging of the well during its operation, at the construction stage, select the pump and filters very carefully. Their compatibility with the diameter of the pipes used is subject to special control;

- the regularity of cleaning the drilled source is the main rule that the owner of the house should follow, who wants to avoid serious material costs when it will be impossible to do the work on his own and have to attract a team of professionals;

- if the drilled source is used only in the summer, in the autumn-winter period it is recommended to run water at least once a month with a pump through the system idle;

- if it is impossible to independently clean the well, you should use the services of specialists.They will quickly solve the problem, since they have at their disposal all the necessary tools and equipment.

Of course, if you plan to use the well for only one season, you can do without casing. But after a lapse of time, the movement of the soil will cause its shedding. Then you will not only be left without water, but also lose some of the equipment - the water supply pipe and filter.