A perforated pipe is a product that is made from a variety of materials: steel, plastic, asbestos and is used for laying drainage communications, as well as for other purposes. Punched products differ from ordinary pipes in that they have holes on their walls, which, as a rule, are arranged in a certain sequence.

Perforated pipes are most in demand in drainage systems, but are applicable in other areas - for example, for the installation of water wells

Content

Perforated Pipe Operations

Perforated products used for different purposes can be divided into several types depending on the shape of the holes:

- round;

- ovoid (oval);

- square;

- rectangular;

- curly.

Consider which options for using such products are the most popular today:

- constructive element of drainage communications. The most popular use of perforated products;

- in supporting structures.

Note! The weight of the perforated pipe is slightly lower than that of conventional pipes; therefore, when mounting the supporting structures from such parts, it is necessary to take into account the fact that the bearing capacity of such a part is slightly less.

- as a silencer on a car. In this case, it is installed in a case, the role of which is played by an ordinary pipe with a solid wall. The result is an ideal sound dampening design.;

- in addition, it is worth noting that such products are used in the installation of ventilation communications in the premises.

The most popular today are two types of such products by material:

- metal (usually made of galvanized steel or stainless steel);

- plastic. Such pipes can be smooth and corrugated.

Perforation of a plastic pipe is much simpler due to the properties of this material.

Punch Features

To date, there are several options for making holes in pipes. The way the pipe is perforated depends on several important factors. Consider them:

- hole shape;

- the relative position of the holes;

- center distance.

As mentioned above, the shape of the hole can be very diverse - from the most common round, to decorative (various patterns). Perforation should be carried out according to previously prepared drawings, and also take into account all the features of the pipes: variety, wall thickness, etc. In most cases, perforation is performed by drilling, however, there are other, more high-tech methods for making holes.

The application of the holes also depends on the material of the pipe. For example, for seamless metal products using laser perforation of pipes. Making holes with a laser is considered a high-tech method that allows you to make holes with a high degree of accuracy with respect to each other.

Plastic pipes are very easy to process, therefore, perforation on such products does not cause any difficulties. When self-perforating plastic parts, it is recommended to pay special attention to the preparatory stage (marking).

Important! Due to the fact that this material is very malleable, instead of drilling, perforation of plastic parts by means of cuts is often used. Such cuts can have a different arrangement (parallel to each other or in a checkerboard pattern).

The execution of cuts is considered the more preferable option, since such a perforation can minimize the loss of strength of the product. In addition, unlike conventional holes, cuts have a large area.

Perforated Pipe Production

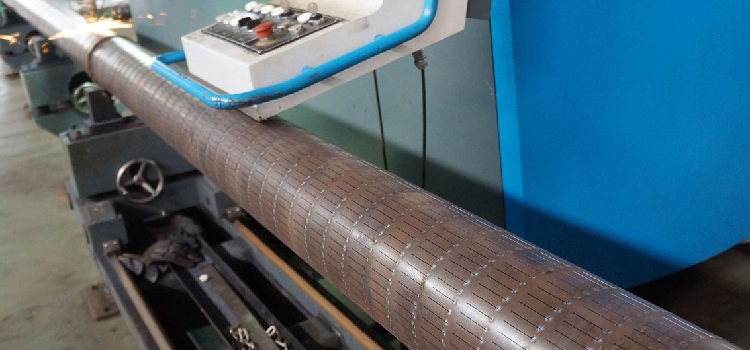

As a rule, perforated products for different purposes are made of standard pipe fittings. In addition, another option is possible: the part is made of a sheet of metal. In the second case, the necessary perforation is first applied to the metal sheet, and after that it is twisted (the sheet is rolled to the required cross-sectional index).

Modern equipment in factories is capable of performing parts with punching of maximum length. The length of such pipes can reach 14 meters, and their cross-sectional parameters vary from 50 to 1650 mm. The wall thickness of products that have gone through the rolling procedure can be from 0.5 to 15 mm.

The metal sheets that go through these procedures are made of various types of steel:

- galvanized;

- stainless;

- carbon.

The holes can reduce the total mass of the part with minimal loss of strength and performance. It is worth noting that such parts are produced on a massive scale and have a wide range of diameters, shapes, and sizes. The cost of such pipes is quite low, which also leads to their high popularity in various fields.

How to make a perforated pipe with your own hands?

As a rule, perforated parts are mass-produced at various factory enterprises, however, if you wish, you can make such products yourself. But, it is worth noting that making holes in the pipe with your own hands is a rather complicated and lengthy process, which also requires high concentration and accuracy.

Let's consider the instructions in stages, according to which the independent production of perforated parts is performed:

- First of all, you need to make the markup suitable for the specific case. You can use a regular marker for this.

- At the second stage, it is necessary to securely fix the part in a vice.

Helpful information! If the dimensions of the part do not allow its fastening, then the pipe is fixed directly on the ground or on any other surface.

- Next, drill holes at the points marked with a marker. Depending on the material, different drills are used.

- At the end, it is necessary to clean the holes from the burrs. If necessary, you can grind the edges of the holes with a file.

Regardless of the purpose for which the perforated part will be used, experts recommend that you first study all the necessary rules, and only then do the holes. If necessary, perforated products can always be ordered at the factory.