GOST 632 provides for the implementation of technical specifications and regulatory guidelines in the production of steel casing pipes. Its intended use relates to casing seamless elements with trapezoidal or triangular threads with couplings. Requirements determine the quality characteristics of high-tight joints with couplings and sleeveless options for bell-shaped structures.

Content

Casing. Their types and varieties

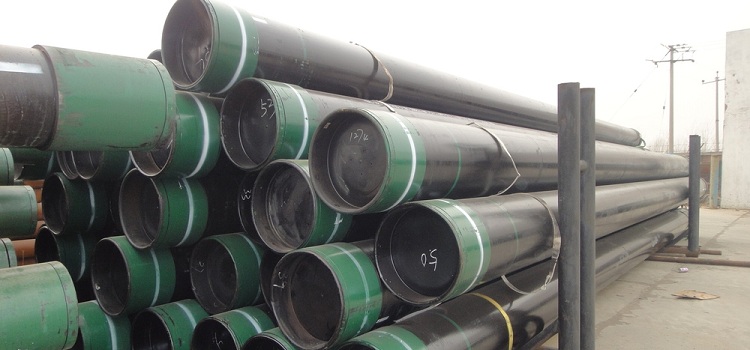

These products are mainly used for mounting brackets in oil and gas wells. The standard describes the types, establishes the appropriate classification, defines the technological aspects of production, controls geometric parameters. GOST requirements apply to test methods, transportation, storage of products.

GOST 632 80 standardizes the production of casing elements in two versions - A and B. They are distinguished by quality indicators, as well as the limits of geometric shapes and manufacturing accuracy. The difference in type is determined by the following indicators:

- by the type of material used, its strength characteristics and grades of steel and coupling joints;

- by variety of types of compounds;

- by the diameter of the product and the thickness of its wall.

The provisions of the standard provide drawings and tabular data separately for different types of connections:

- for elongated threaded connections, type U;

- for short threads and couplings;

- for products with a trapezoidal shape of a thread like OTTM;

- for threaded versions of high-tight joints, type OTTG.

The standard length of the manufactured casing pipes for types A and B is in the range from 9.5 to 13 meters. The tolerance is established for the production quantity in a batch along the lengths of type A and B, which must be suitable for OTM (triangular and trapezoidal threads):

- with a size of 8 - 9.5 meters up to 20% of the total;

- from 5 to 8 meters - no more than 10%.

Changing this tolerance is possible only by agreement with the customer of the products. Casinghaving a high-tight OTTG type joint, as well as solid-state solid waste type couplings are produced in sizes of 9.5 - 13 meters. With the consent of the customer, up to 20% of pipes from 8 to 9.5 meters long can be allowed.

Important! The provisions of the standard regulate the boundary tolerances for the size and weight of pipes, couplings according to the types of OTTM, OTTG and MSW. However, he does not establish such requirements for a batch of Type A casing, weighing up to 60 tons.

Basically, in countries that comply with this GOST, pipes with a diameter of 114 mm to 508 mm and a length of 9.5 - 13 meters are produced. Depending on the installed pipe diameter, the wall thickness is 5 - 16 mm. According to the list of strength characteristics, 7 groups for casing are distinguished: –T, P, M, L, E, K, D, where each of these strength groups corresponds to the desired steel grade. Accordingly, each pipe produced has a marking that corresponds to the diameter, strength group, wall thickness, current number with the date of production.

Basic data and technical parameters and requirements

The pipe itself and its connection should be made without sinks, technical and technological flaws, metal delamination and cracks. The resulting defective areas can be cleaned if the norms of the maximum size are maintained in its minus deviation. Defects such as dents, nicks and sagging are allowed provided that they do not exceed the established minus deviation.

Requirements are established for minimizing defects for socket joints. The casing pipe, as well as the coupling, are made of material of the strength grade that is specified in GOST. Standards such as the specific gravity of sulfur and phosphorus in steel are established, which should not be higher than 0.045%, respectively.

GOST 632 80 establishes the order of thermal quenching, threaded connections, couplings by type and type. Manufactured casings are tested for flattening. Standards for the test procedure are established by the provisions of this standard.

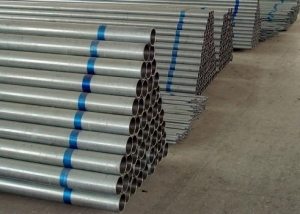

When manufacturing, attention is drawn to the fact that the threads and conical parts of the coupling joint are galvanized and phosphated. Products with a triangular thread at one of its ends contains a sleeve. The connection is provided with a lubricant of the established type to protect against corrosion and maintain performance. At the request of the customer, pipes and couplings can be painted.

Products with couplings and with couplings are subject to hydraulic tests. The standards of such tests, their parametric data for each of the types, strength indicators are also established by this standard.

GOST 632 80 casing pipes - a source of establishing data on all elements of manufactured products. In particular, on the parameters of threaded connections. The dimensions of the threads, their shape, processing, manufacturing tolerances are determined by the drawings and tabular data for each type given in the standard. The requirements for various types of sleeve and sleeveless, bell-shaped joints are:

- the end parts of the pipe, the coupling and its thrust ledges are perpendicular to the axis of the thread;

- the deviation level for this parameter is not more than 0.06 mm;

- the axis of the threaded joints of the couplings and pipes should coincide with a deviation of not more than 0.04 mm;

- the marginal errors of the taper during connection must be observed;

- the value of the interference fit of the socket connection must be in accordance with the requirements for this type of connection and is determined in the corresponding tables.

It's important to know! The level of surface roughness of the compounds should not be higher than 20 microns.

Practical acceptance of casing pipes, test procedure

According to the requirements of GOST 632 80, casing acceptance is carried out in batches. The party consists of products with the same technical characteristics, their configuration and purpose. Accordingly, these requirements are drawn up and documents for a batch of products.

Their contents include:

- name of the producer, his brand name.

- the established diameter of the manufactured products, their type, length and weight.

- established type of performance.

- typical product mix.

- group strength, data on the inclusion of sulfur, phosphorus in each of the melts performed.

- product numbers corresponding to each metal smelting.

- indication of the standard and test data.

Verification is subject to the appearance of each element. The condition of the joint threads, their compliance with the standards of the standard in terms of type and type of products is also subject to verification. Check the connection of pipes and couplings, the mass of products of type A and B. Correspondence of mechanical strength is checked by the method of selection of products from each melting of metal. The same method applies to flattening tests.Types A and B are subjected to hydraulic resistance with and without couplings installed on them (type MSW). To find defects in the pipe body and coupling joints, the method of ultrasonic testing and magnetic induction testing is used.

Good to know! The tightness control of threaded joints is subject to acceptance.

For product testing, the provisions of GOST 632 80 define the following requirements:

- surface control to determine visible defects is carried out visually;

- geometric dimensions and installation standards for tolerances are determined using appropriate attorney measuring instruments and devices;

- compliance with the parameters of the internal dimensions is performed by the template throughout the length of the pipe with a deviation from the installed sample of +0.25 mm

- control of the curvature of the end sections of the pipes;

- coincidence along the axes of the threads is carried out by installing a runout in the joint.

Marking is carried out by rolling information or by percussion. Application of light technical information duplicates the mechanical marking method. When storing products, threaded joints, pipe ends and conical surfaces are protected from mechanical damage with the help of special metal rings and nipples. They protrude over the edges of products by 10 mm or more. The end surfaces of the products are coated with anti-corrosion grease.

Products are stored and transported in bags. Products of the same type can be packed in one batch bundle. Lot weight - up to 5 tons.