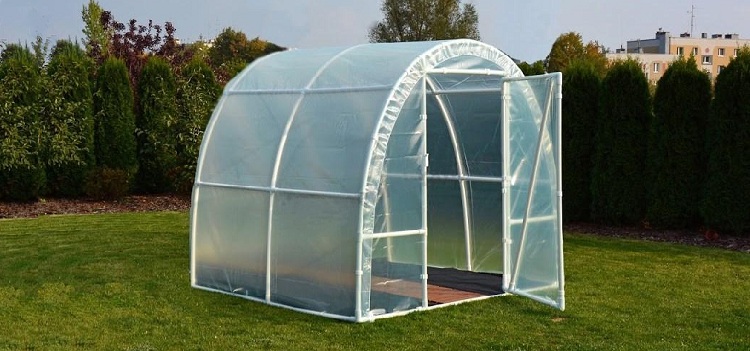

In order to build a greenhouse on your site, the summer resident needs to stock up on materials and free himself for a maximum of two days from other activities in order to rush to construction without haste. A small greenhouse is constructed of plastic pipes with your own hands simply and very quickly, it requires very little financial investment and physical effort. And the time spent pays off by the opportunity to enjoy, almost all year round, their agricultural products.

A greenhouse whose frame is made of polymer pipes is a popular option among amateur gardeners and professionals.

Content

The advantages of building from polymers

In terms of their operational and qualitative characteristics, plastic structures are not inferior, and in some properties they even surpass metal and wooden structures. Plastic, unlike metal, is resistant to corrosion, and is not subject to decay, like wood. Polymer pipes are strong and at the same time lightweight, do not burden the structure, which does not require the installation of a complex foundation, moreover, without prejudice to the ability to withstand high loads.

Plastic belongs to the category of flexible materials, that is, it bends well. Due to this property, it is possible to give the pipes the necessary configuration without much effort. This allows you to realize a greenhouse of any shape. For example, in the form of a house with a pitched or gable roof, in the form of an arch, and even a structure with complex stereometry.

Thus, greenhouses made of plastic pipes have the following advantages:

- long service life with properly completed assembly;

- environmental safety for green spaces and soil;

- the design is characterized by ease of adaptation to the fantasies and needs of the owner of the land plot;

- you can do the installation yourself without the involvement of specialists;

- simple dismantling with subsequent transfer to another place;

- relatively low cost;

- absolute corrosion resistance. Even a galvanized pipe will eventually rust;

- attractive appearance.

The polymer frame will be lightweight but durable, will not require painting or other corrosion protection

Construction Preparation Phase

Before proceeding with the construction of a greenhouse from plastic pipes, it is necessary to create a drawing, based on which it is calculated what and how much material is required.

Note! Among other things, this will save you money by avoiding the purchase of surplus.

Choosing a place under the greenhouse. This question is far from idle. The installation location affects the level of development of the planted plants, which ultimately determines the amount of the future crop. For the considered option of the greenhouse, it is advisable to choose a sunny and open area without a shadow from country houses and trees. This requirement follows from the fact that vegetables with a lack of natural light will poorly develop and grow slowly. Therefore, the greenhouse is best placed along the East-West parallel. Then the lighting will be present in it throughout the daylight hours, due to which the optimal growing conditions will be created for the plants.

Greenhouse design and determination of the amount of material required. It is quite difficult to make a design drawing for a layman on your own. But today you can find many ready-made projects and, taking one of them as a basis, perform the necessary calculations. As an example, the question of building a greenhouse with a length of 6, a width of 3 and a height of 2 meters will be considered below. To make it, you will need:

- plastic pipes in the amount of 15 pieces 6 meters long. They will go to arches, two pediments, couplers and additional elements;

- a beam or boards of the same length for the base and thin wooden planks for fixing the film coating;

- tees and crosses. With their help pipes will be connected;

- plastic film for covering the greenhouse. Width - 6 meters, a total area of 36 square meters. m;

- rebar in the amount of 24 units 0.75 meters long;

- hinges, door hinges, handles, plastic clamps, staples, angles, nails and screws.

When calculating pipe footage, add 10% for contingencies.

Most often, greenhouses are built in which the role of the screed is played by one pipe located in the center. Front doors can only be installed on one side, but on the other, a blank wall with an opening for a window can be created.

Basic materials and requirements for them

From the whole variety of plastic pipes for greenhouses, it is best to choose made from polyvinyl chloride or polypropylene products. They withstand temperature extremes well, do not deteriorate when exposed to high temperatures and are resistant to frost. It is recommended to build greenhouses from polymer pipes with a diameter ranging in the range of 13 ... 25 millimeters.

Since it is not necessary to install the foundation under the greenhouse, a beam of 30 × 30 millimeters or wooden boards are used to equip the base. Their recommended thickness is 20 ... 40 millimeters.

If the project provides for the use of film as a coating, stop your choice on reinforced. A cheaper option is the use of textile material such as "agrotex", but its degree of thermal insulation leaves much to be desired. The undisputed leader in the strength and durability of the coating is polycarbonate. The optimum sheet thickness of this material for greenhouses is 4 ... 8 millimeters.

On a note! The use of polycarbonate will increase the cost estimate. But then the coating created from it will serve for at least 10 years. What can not be said about the plastic film.

The plastic film is short-lived, it is suitable only for a temporary greenhouse, which will be used for 1-2 seasons

Preparing a place to build

Before creating the foundation, you need to prepare the site. In general, the greenhouse should be installed on a site without pits, humps and other irregularities. The site is prepared by removing a small layer of soil a meter longer and wider than the future structure.

To create a more durable and stable greenhouse from plastic pipes, dig a trench around the perimeter. Its width and depth are derived from the dimensions of the timber or board. These elements should be half buried in the ground. Then pour crushed stone to the bottom, and then lay the roofing material.

To check the evenness of the site, use the building level and, if necessary, level the surface. Allowed height difference is 5 centimeters. If there is a significant slope on the site, the greenhouse area is leveled with the help of boards. They simply stack on top of each other on the side with the largest recess until they reach an identical level with the opposite side.

Greenhouse construction stages

Upon completion of the preparatory work, you can begin to create a design.

We make the foundation. For this, wooden boards are used. Professionals recommend sanding them with sandpaper or stripping them with a planer.It should also be taken into account that without special treatment, the tree can rot over time. Therefore, to prevent this phenomenon, cover the boards with antiseptic protective preparations.

A wooden frame is assembled directly on the site prepared for the greenhouse. To fasten the boards together, nails or galvanized screws are used. In the case of using beams for foundation, they are joined by half-tree cutting, that is, without metal elements.

Having made the frame, install it in the trench and cover it with soil firmly so that there are no gaps or gaps. In order to give the wooden foundation greater reliability, professionals recommend additionally fastening the internal joints of the boards with steel corners. To fix the frame, drive a reinforcement into each corner. The rods are also clogged from the inside or outside of the long boards in increments of 67 centimeters. They should protrude above the surface by 40 centimeters.

We make a frame from plastic pipes. The simplest installation option for the frame is as follows:

- one end of the plastic pipe is put on a metal pin, previously driven into the ground;

- the other edge is mounted on the opposite shaft. In the end, you should form an arc.

- for durability on both sides, screw them with metal brackets to the wooden base.

We install the ends of the greenhouse. This process includes the following steps:

- with the help of plastic tees and corners, pipes and doors are assembled from pipes;

- to strengthen the door, a diagonal strip is laid from the bottom to the middle line;

- 2 tees are put on the arched arc located at the edge at a distance corresponding to the width of the opening, by means of which the door block is attached to it;

- Before installing the door and window openings in the main structure, wrap them with plastic wrap.

Advice! You can fix it on the pipes with double-sided tape or using self-tapping screws.

We cover the frame with a film:

- distribute the film over the entire structure of the greenhouse so that there is an even supply on both sides of it;

- then nail the film to the wooden frame with nails, fixing it with planks. First, moving to the corners from the center, fasten one side. Then, pulling the material well, do the same procedure on the other side;

- the deaf ends of the greenhouse deal last. To fix the film in this case, you can use not a plank, but a furniture stapler.

In conclusion, it must be said that galvanized greenhouses from galvanized pipes act as competitors to greenhouses made of plastic load-bearing elements. So, they are usually covered with polycarbonate. And it is justified. This material can withstand even a stone blow, which is not a curiosity in the realities of life in rural areas.