Many owners of private houses opt for an autonomous water supply system. This solution becomes especially relevant when it is impossible to connect to a centralized network. The process of setting up a modern long-term well is rather complicated. The choice of the main elements of the system - plastic pipes for wells (casing) - must be approached with care.

Content

Varieties of casing

Well casing is carried out in order to prevent collapse of its walls during operation and to prevent penetration of water present in the upper aquifers into the system. To do this, apply:

- plastic pipes;

- metal pipe products;

- products from asbestos cement.

The choice of material affects the life of the well. Metal pipes are used quite often, especially where the aquifer is at great depths. Durability is the main advantage of such a technical solution. The service life of such a casing is about 50 years. However, there is one significant drawback - the steel casing pipe will inevitably rust. And this phenomenon will cause a deterioration in the quality of the water itself. Therefore, the use of metal products without fail implies the additional installation of special filters. Experts believe that the best option for the use of steel pipes is the casing of artesian water sources, where the pressure is always increased.

Become familiar with the mechanical properties of the steels used in the production casing pipe, you can by examining the data from the table below.

Table 1

| Characteristics | Steel Strength Group | ||||

| M | L | E | TO | D | |

| Relative extension, % | 10,8 | 12,5 | 13 | 12 | 16 |

| Yield Strength, MPa No more no less |

964 758 |

861 655 |

758 551 |

-490 |

551 372 |

| Temporary resistance, MPa. | 861 | 758 | 690 | 687 | 637 |

Asbestos cement products began to be used for casing for a long time. Along with positive characteristics - a long operational period and low cost - these pipes have the following disadvantages:

- monetary, time and physical costs increase because because of the considerable wall thickness it is necessary to drill channels with a large diameter;

- where the ground pressure is quite high (and this is fixed at a great depth), the strength of asbestos cement pipes is insufficient.

If water should be suitable for household needs, then pipes should be selected that do not affect its quality

Important! Over time, asbestos can adversely affect the quality of drinking water.

Therefore, regardless of the diameter of the casing for the well made of this material, its installation must be carried out only under certain conditions. The main ones are formulated as follows:

- installation should be carried out by a specialized company;

- installation is carried out in limestone soils;

- the product must have a hygiene certificate.

What materials are casing plastic structures made of?

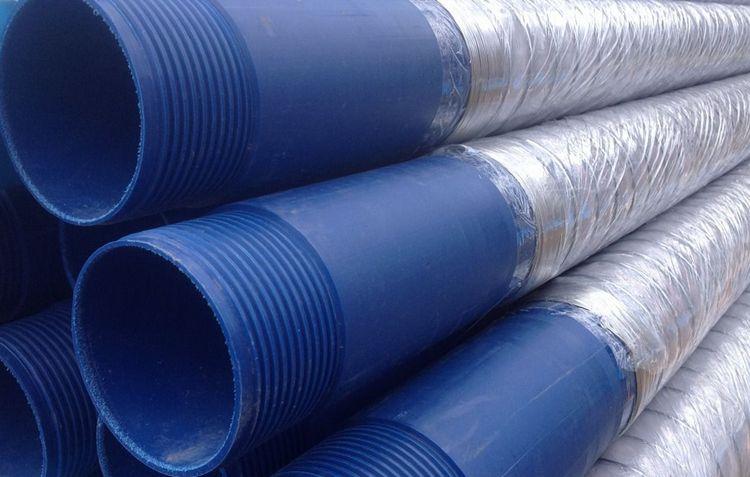

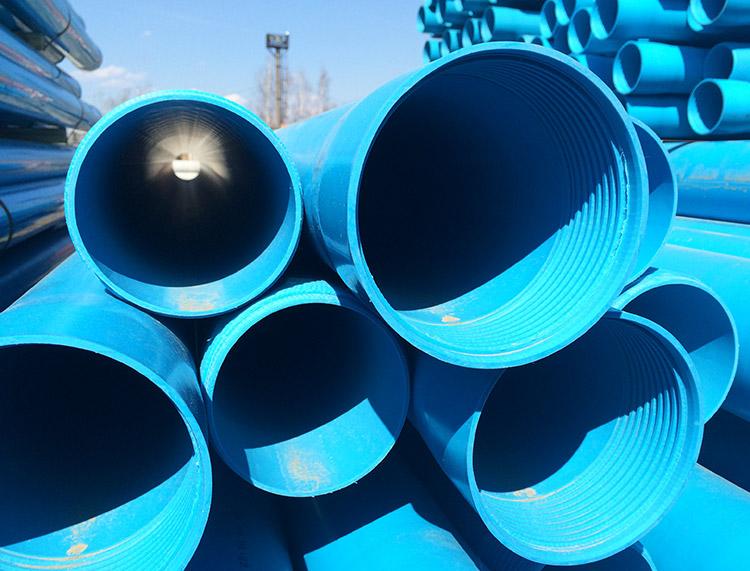

Recently, plastic pipe products have become very common in channel casing.This type of product has excellent performance characteristics. Their advantages include:

- long term of operation;

- good tightness of joints;

- simple installation;

- light weight;

- low cost;

- resistance to corrosion;

- resistance to chemically aggressive substances.

Plastic pipes for water intake made from several types of polymer raw materials. Briefly consider them.

Unplasticized polyvinyl chloride. When compared with analogues, products from NPVC have the best performance for use as casing strings. They belong to the category of high-strength materials, have a low level of thermal conductivity, a small coefficient of linear expansion and are characterized by high quality connecting components. In addition, this material is resistant to chemical influences. Due to the combination of these properties, the columns from the PVC-U will not allow underground drains into the filtration zone.

Polyvinyl chloride. Using PVC pipes for casing wells also a great solution. This is due to the following factors. Firstly, even if the water in their cavity freezes, the PVC pipes will not burst. Secondly, the water passing through the columns does not become unpleasant to the smell. And thirdly, no deposits form on the inner walls.

A trapezoidal thread is present on these products. Accordingly, the type of connection is threaded. Depending on the diameters of the casing plastic pipes made of polyvinyl chloride, their length varies in the range of 3 Low strength is perhaps the only drawback of this type of pipe products. Therefore, lower the PVC casing should be strictly vertical. But if the trunk is very deep, it is difficult to fulfill this requirement. Low-pressure polyethylene. This material has an increased density. It is resistant to a variety of dynamic loads, and is also able to withstand compressive and tensile deformation. The cavity of the PND pipe does not overgrow. These products are not afraid of the effects of chemicals and, of course, corrosion. When performing casing operations, polymer pipe products can be assembled independently, but its combination with steel pipes is also allowed. The descent of plastic structures of all types of milestones (NPVH, PND and PVC) is performed in the same way as metal elements. Below is an example with specific numbers. Advice! If the connection is made by a threaded connection, seal it additionally with rubber seals. This will prevent the penetration of water from the upper layers of the soil into the trunk. The wellbore must be smooth, otherwise the whole structure may break when lowering the casing elements. A very important point is the method of connecting the pipes. When choosing it, you always need to remember the main task of the casing structure - maintaining tightness. Today, there are three ways to dock its elements. Threaded connection. Experts attribute the use of threaded pipes to the category of smart solutions. But there is one caveat: the advantage in the form of high reliability of joints is offset by the relative high cost of this method. Many ordinary inhabitants may have a question related to the size of casing pipes for wells.It sounds like this: is it possible to use threaded fittings if the length of the casing elements is about 13 meters? Yes, it is allowed, but it should be noted that in this case the useful internal diameter of the well may decrease. And this factor limits the choice of a submersible pump. Welding connection. This is a very dubious method, since the tightness of the welds depends on the level of professionalism of the welder. And even if the work is done efficiently, it should be taken into account that it is welds that are the least resistant to corrosion. Therefore, the life of the casing string is reduced. Welding is considered more acceptable technology for arranging highways in open areas. Then there is the opportunity to timely detect the destruction of the joint and stop it before an emergency occurs. Installation in a bell. In this case, the pipes are connected through an o-ring. You can call this method reliable only with a big stretch. This is due to the lack of the ability to control the quality of the installation of pipes and the probability of subsidence during operation. As you know, pipes are: To design casing strings, purchase only products of the second type, since soil pressure will be inevitable. The diameter of the pipe will depend on the purpose of the well and the planned volume of water consumption. The diameters of the plastic casing pipes are calculated taking into account the type of pump intended for use. So, if the aquifer in the house has an increased static and dynamic water level, the pump must be in a suspended position in the casing. Advice! You can find out up-to-date information on the above indicators by contacting the organization that is drilling wells in your area. For a correct understanding of how the calculation is performed, we will consider the option with a water flow rate in the building of about 3 cubic meters per hour. To ensure such a volume of consumption, a pump with a diameter of 75 millimeters is suitable. From this figure and repel. To calculate the diameters of casing steel pipes for wells, perform the following arithmetic operation: 75 + 8 + 4 = 87 mm. Here: 75 is the diameter of the pump, 8 is the wall thickness of the pipe, 4 is the gap between the pump and the pipe. The unit of measurement for these characteristics is millimeters. All casing pipes are standard sizes. Having studied GOST 632-80, we can conclude that the diameter 114 mm is most suitable for the resulting figure. If you plan to use a pump with a diameter of 102 millimeters, the calculation of a suitable section of the pipe is carried out similarly: 102mm + 8mm + 4mm = 114 mm And although this figure is contained in GOST 632-80, it is recommended to purchase with a margin of 127-140 mm. The range and dimensions of casing pipes are determined by GOST 632, which was adopted in 1980. He divides similar products into several types. When choosing pipes, it is important to pay attention to the type of thread, it is different on different types of products Namely: Good to know! The diameter of the bell-shaped bulge is limited to 136 and 206 millimeters, respectively. In conclusion, a few words about the features of the casing string An attempt to save on the purchase and installation of casing will lead to collapse of the soil from the walls of the well and make it and the equipment located in it unsuitable for use. And to restore all this will require additional costs. Casing features and pipe connection options

Pipe selection

Assortment of casings