Polished stainless pipe is used in the food, chemical and pharmaceutical industries, in the manufacture of furniture; it is indispensable in interior, facade and landscape design. Its main advantage is an aesthetic appearance with high structural reliability. Depending on the manufacturing method, it may have increased strength, wear resistance or anticorrosion.

Content

Key Features of Polished Stainless Pipes

Grinded stainless pipes are mainly made of steel, which, in addition to iron, contains chromium. Depending on the brand and purpose, other chemical elements can be added to the alloy, due to which the material acquires additional properties.

The mirror surface is the result of polishing, which is carried out in three ways: mechanical, thermo- and electrochemical. The sanded construction has no planar or structural defects, as a result of which the pipe becomes suitable for use in areas requiring impeccable smoothness.

Such a profile metal construction combines beauty and strength, durability and wear resistance. In each city, you can get a visual representation of how much stainless steel is in demand in the modern world. In any medical institution, in food concerns, a mirror piping system is used. Just like almost every office and shopping center boasts shiny handrails on the stairs.

Types of pipe blanks and methods for their manufacture

The polished stainless steel pipe is of two types:

- welded;

- seamless.

Welded

Now there are several methods for making a seam. Basically, profile pipe metal construction is made using the following types of welding:

- welding with a tungsten electrode in an inert gas environment. The electrode is not consumed, it only creates an electric arc, causing the edges of the product to melt and weld together;

- high frequency induction welding;

- laser welding;

- electron beam welding. The peculiarity of the process is that it takes place in a deep vacuum.

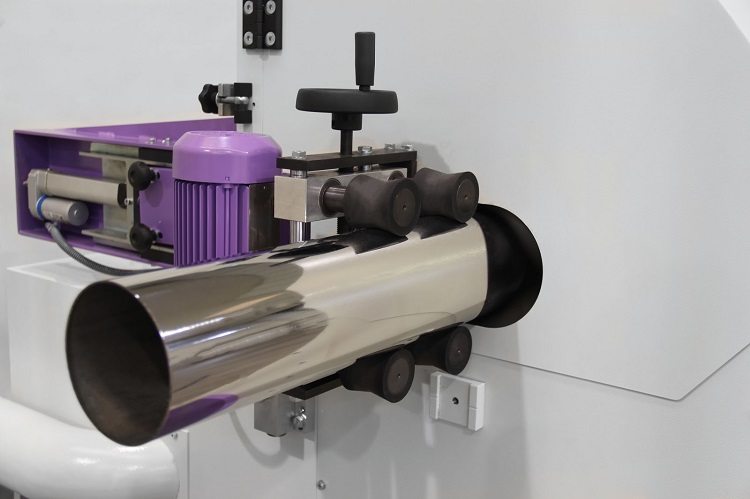

The production technology looks like this: flat stainless steel is folded into a tube, boiled along the seam, calibrated in the rollers and passes the tightness control. Then the pipe is sent for polishing, as a result of which minor defects are eliminated and, if necessary, a mirror reflective surface is acquired.

Seamless

By casting or pressing, a round and hollow stainless billet is made - the future pipe, which is to be processed and calibrated in rollers.

According to the temperature at which it is processed, they distinguish: hot-deformed products, heat-deformed and cold-deformed.

Helpful advice! For the second and third categories, it is important to find out whether the profile blank has passed heat treatment. According to GOST, it is mandatory: the pipe is calcined and cools, freeing itself from the internal stresses of the metal. If you save at this stage, the strength decreases.

Methods of surface treatment of the finished product

Regardless of the manufacturing method, a polished surface is obtained according to one principle.

Two main methods of processing polished stainless pipes can be distinguished: electrochemical and abrasive.

Electrochemical method

The product is immersed in a solution of concentrated acid. Then, depending on whether a polished surface is required on the outer or inner part of the workpiece, it is either surrounded by a round electrode, or the electrode is inserted inside. After that, a large current is supplied to it.

Abrasive method

Primary coarse abrasive treatment is possible at the manufacturing stage. By the way, this is how the cheapest stainless steel mirror pipe is obtained.

The abrasive method does not require large expenses, therefore, pipes obtained in this way are notable for their affordable price

The polished surface is gradually becoming smoother due to the consistent use of abrasive substances with decreasing grain size. Mirror polishing is done with felt sanding belts.

It is interesting! The stainless workpiece has the advantage: in addition to dry abrasive processing, wet polishing is also possible. The only difference is that the abrasive particles are carried by water. The rest is the same use of abrasive particles of an ever smaller size.

Established GOST standards and sizes of stainless pipes

Steel marking is regulated by the requirements of EN 10088-1, GOST 5632-72. Sampling for determining the chemical composition is carried out according to GOST 7565-81.

Depending on the purpose, the mirror polished pipeline system can be:

- intended for structures used in the food, chemical and pharmaceutical industries - DIN 11850;

- intended for domestic and decorative purposes - DIN 17455, EN 10296-2.

As for the dimensions, they are the same as for any other pipelines based on stainless steel:

- GOST 9940-81 seamless hot deformation pipes can have a diameter from 57 mm to 325 mm, wall thickness from 3.5 mm to 32 mm;

- GOST 9941-81 seamless cold and warm deformation pipes are produced with a diameter of 5 mm to 273 mm and wall thicknesses of 0.2 mm to 22 mm;

- welded pipes GOST 11068-81 come in diameters from 8 mm to 102 mm with walls with a thickness of 0.8 mm to 4 mm.

The polished design of small diameters is most in demand, and strength most often comes second after appearance and wear resistance. Therefore, the profile model that was manufactured by the welded method is in greatest demand in the country. And, as a result, the vast majority of pipes, which are based on the appearance of mirror processing, are made that way.

Profile pipe billet: applications and advantages

Bacteria do not stay on polishing simply because they have nothing to eat there: dirt does not accumulate on the surface. Another advantage is the fact that stainless steel is chemically stable: milk or syrup will not be enriched with iron oxides.

Doctors are also interested in this feature of the material. In addition to tools, polished pipe is used in the manufacture of implants. They are not rejected by the body’s immune system precisely because the stainless steel is completely chemically stable.

Therefore, profile mirror stainless pipes, like no other, are in demand in the food, chemical and medical industries.

Important! When it comes to purchasing materials for food concerns and factories for the production of medical equipment, it is necessary to clarify what type of welding was used in the manufacture.If HF welding was used, models are not recommended for the implementation of pressure pipelines in these industries.

Also in practical implementation, a polished stainless steel pipe is:

- heated towel rails and other pipeline communications, the location of which requires that they be used based on polished, that is, an aesthetically attractive profile steel;

- systems in bathrooms, in the kitchen, in baths, saunas, in interior and landscape fountains;

- staircases, railings, railings, entrance groups;

- modern furniture, frame racks for delimiting the space in shopping centers and office premises;

- pipeline elements in food and medical equipment.

For indoor use, the polished AISI201 is best suited. In the external environment, the pipe AISI304, AISI304L is used. For aggressive environments (fences near the sea, in pools, on yachts, etc.) AISI316L is best suited.