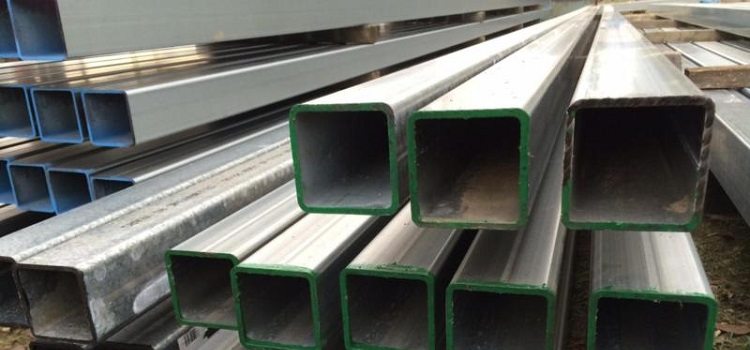

Profile pipes are made of special grades of steel, which give them additional stability and reliability. Due to their properties, such products are widely used in many areas of life: food, chemical, energy industries, welded metal structures, supports, etc. The range of pipes is very diverse. The cross-sectional shape of shaped products can be square or rectangular.

Content

Variety of products

In addition to the cross-sectional shape, profile pipes are divided by the type of coating, which happens:

- matte;

- polished;

- mirror image.

Pipes with a matte surface are used as structural elements, which do not have any special requirements in appearance. This can be production racks, supports, work sites, etc. Usually, such products are made of AISI 304 steel by the electric-welded method and have a square section.

Profile pipes of the mirror type can be square or rectangular and are used for interior and exterior decoration of buildings and premises, for the installation of metal structures, in mechanical engineering, etc.

Grinding the surface in a special way gives the profile pipe a decorative look and increases its corrosion resistance, and the surface of the products becomes uniform in both color and quality. Inside, the weld of the pipes is not processed.

Profile stainless pipes: assortment

According to GOST 8639, the assortment of square products includes products with the parameters presented in the table.

Table 1

| Wall length * 102 mm | Wall, * 10-1 mm | Weight 1 meter product, * 10-1 kg | Sectional area, * 10-1 cm2 |

| 0,1 | 10 | 2,69 | 3,43 |

| 0,15 | 10 | 4,26 | 5,43 |

| 15 | 6,05 | 7,71 | |

| 0,2 | 10 | 5,83 | 7,43 |

| 15 | 8,41 | 10,71 | |

| 20 | 10,75 | 13,7 | |

| 0,25 | 10 | 7,40 | 9,43 |

| 15 | 10,7 | 13,7 | |

| 20 | 13,9 | 17,7 | |

| 25 | 16,8 | 21,4 | |

| 30 | 19,5 | 24,8 | |

| 0,30 | 20 | 17,0 | 21,7 |

| 25 | 20,7 | 26,4 | |

| 30 | 24,2 | 30,8 | |

| 35 | 27,5 | 35,0 | |

| 40 | 30,4 | 38,8 | |

| 0,35 | 20 | 20,2 | 25,7 |

| 25 | 24,6 | 31,4 | |

| 30 | 28,9 | 36,8 | |

| 35 | 33,0 | 42,0 | |

| 40 | 36,7 | 46,8 | |

| 50 | 43,7 | 55,7 | |

| 0,40 | 20 | 23,3 | 29,7 |

| 25 | 28,5 | 36,4 | |

| 30 | 33,6 | 42,8 | |

| 35 | 38,5 | 49,0 | |

| 40 | 43,0 | 54,8 | |

| 50 | 51,6 | 65,7 | |

| 60 | 59,2 | 75,4 | |

| 0,42 | 30 | 35,5 | 45,2 |

| 35 | 40,7 | 51,8 | |

| 40 | 45,6 | 58,0 | |

| 50 | 54,7 | 69,7 | |

| 60 | 63,0 | 80,2 | |

| 0,45 | 30 | 38,3 | 48,8 |

| 35 | 44,0 | 56,0 | |

| 40 | 49,3 | 62,8 | |

| 50 | 59,4 | 75,7 | |

| 60 | 68,6 | 87,4 | |

| 70 | 76,9 | 98,0 | |

| 80 | 84,3 | 107,4 | |

| 0,50 | 30 | 43,1 | 54,8 |

| 35 | 49,4 | 63,0 | |

| 40 | 55,6 | 70,8 | |

| 50 | 67,3 | 85,7 | |

| 60 | 78,0 | 99,4 | |

| 70 | 87,9 | 112,0 | |

| 80 | 96,9 | 123,4 | |

| 0,60 | 35 | 60,4 | 77,0 |

| 40 | 68,2 | 86,8 | |

| 50 | 83,0 | 105,7 | |

| 60 | 96,9 | 123,4 | |

| 70 | 110,0 | 140,0 | |

| 80 | 122,0 | 155,4 | |

| 0,70 | 40 | 80,7 | 102,8 |

| 50 | 98,7 | 125,7 | |

| 60 | 115,7 | 147,4 | |

| 70 | 131,9 | 168,0 | |

| 80 | 147,1 | 187,4 | |

| 0,80 | 40 | 93,3 | 118,8 |

| 50 | 114,4 | 145,7 | |

| 60 | 134,6 | 171,4 | |

| 70 | 153,8 | 196,0 | |

| 80 | 172,2 | 219,4 | |

| 0,90 | 50 | 130,0 | 165,7 |

| 60 | 153,4 | 195,4 | |

| 70 | 175,8 | 224,0 | |

| 80 | 197,3 | 251,4 | |

| 1,00 | 60 | 172,2 | 219,4 |

| 70 | 197,8 | 252,0 | |

| 80 | 222,5 | 283,4 | |

| 90 | 246,2 | 313,7 | |

| 1,10 | 60 | 191,1 | 243,4 |

| 70 | 219,8 | 280,0 | |

| 80 | 247,6 | 315,4 | |

| 90 | 274,5 | 349,7 | |

| 1,20 | 60 | 209,9 | 267,4 |

| 70 | 241,8 | 308,0 | |

| 80 | 272,7 | 347,4 | |

| 90 | 302,8 | 385,7 | |

| 1,40 | 60 | 247,6 | 315,4 |

| 70 | 285,7 | 364,0 | |

| 80 | 322,9 | 411,4 | |

| 90 | 359,3 | 457,7 | |

| 1,50 | 70 | 307,7 | 392,0 |

| 80 | 348,1 | 443,4 | |

| 90 | 387,5 | 493,7 | |

| 100 | 426,1 | 542,8 | |

| 1,80 | 80 | 423,4 | 539,4 |

| 90 | 472,3 | 601,7 | |

| 100 | 520,3 | 662,8 | |

| 120 | 613,6 | 781,7 | |

| 140 | 703,3 | 895,9 |

Special sizes are also available.

Production of stainless steel profile pipe

The basis for the production of products is rolling from blanks. If electrowelded billets are used, then the manufacture of a profile pipe is governed by GOST 11068, if seamless, GOST 9940 (for hot-formed, cold-worked).

To get a profile pipe, the workpiece is driven through special rollers - rollers, which give it the desired shape

Note! Stainless steel profile pipe can be made from different grades of steel: AISI 201, AISI 304, AISI 430, etc.

Profile stainless steel tubes (square) can be produced from stainless steel by the method of hot, cold deformation, by the electric-welded method, as well as by the methods of electric-welded hot calibration and furnace welding.

The first method is selected if an external size of 0.6-1.8 is required (* 102) mm and the wall 0.4-1.4 (* 10) mm. Cold deformation is usually applied with the required external dimensions of 0.01-0.1 (* 103) mm with a wall thickness of 1-8 mm. The electric-welded method for producing profile pipes is characteristic for the size of the finished product 0.01-0.1 (* 103) mm and a wall of 0.8-5 mm, electrowelded hot calibration - for 1-1.8 (* 102) mm and a wall of 4-14 mm, furnace welding - 0.04-0.07 (* 103) mm and wall 0.3-0.5 (* 10) mm.

Assortment of rectangular products

8645 rectangular pipes have the parameters given in the table.

table 2

| Side Length * 102 mm | Side Length * 10mm | Wall mm | Sectional area, * 10-1 cm2 | The mass of one meter, * 10-1 kg |

| 0,15 | 1,0 | 1 | 4,43 | 3,48 |

| 1,5 | 6,21 | 4,88 | ||

| 2 | 7,71 | 6,05 | ||

| 0,20 | 1,0 | 1 | 5,43 | 4,26 |

| 1,5 | 7,71 | 6,05 | ||

| 2 | 9,71 | 7,62 | ||

| 0,20 | 1,5 | 1 | 6,43 | 5,05 |

| 1,5 | 9,21 | 7,23 | ||

| 2 | 11,7 | 9,19 | ||

| 2,5 | 13,9 | 10,9 | ||

| 0,25 | 1,0 | 1 | 6,43 | 5,05 |

| 1,5 | 9,21 | 7,23 | ||

| 2 | 11,7 | 9,19 | ||

| 2,5 | 13,9 | 10,9 | ||

| 1,5 | 1 | 7,43 | 5,83 | |

| 1,5 | 10,7 | 8,41 | ||

| 2 | 13,7 | 10,8 | ||

| 2,5 | 16,4 | 12,9 | ||

| 0,3 | 1,0 | 1 | 7,43 | 5,83 |

| 1,5 | 10,7 | 8,41 | ||

| 2 | 13,7 | 10,8 | ||

| 2,5 | 16,4 | 12,9 | ||

| 3 | 18,8 | 14,8 | ||

| 1,5 | 1 | 8,43 | 6,61 | |

| 1,5 | 12,2 | 9,59 | ||

| 2 | 15,7 | 12,3 | ||

| 2,5 | 18,9 | 14,8 | ||

| 3 | 21,8 | 17,1 | ||

| 2,0 | 1 | 9,43 | 7,4 | |

| 1,5 | 13,7 | 10,8 | ||

| 2 | 17,7 | 13,9 | ||

| 2,5 | 21,4 | 16,8 | ||

| 3 | 24,8 | 19,5 | ||

| 0,35 | 1,5 | 1,5 | 13,7 | 10,8 |

| 2 | 17,7 | 13,9 | ||

| 2,5 | 21,4 | 16,8 | ||

| 3 | 24,8 | 19,5 | ||

| 3,5 | 28 | 22 | ||

| 2,0 | 1,5 | 15,2 | 11,9 | |

| 2 | 19,7 | 15,5 | ||

| 2,5 | 23,9 | 18,8 | ||

| 3 | 27,8 | 21,9 | ||

| 3,5 | 31,5 | 24,7 | ||

| 2,5 | 1,5 | 16,7 | 13,1 | |

| 2 | 21,7 | 17 | ||

| 2,5 | 26,4 | 20,7 | ||

| 3 | 30,8 | 24,2 | ||

| 3,5 | 35 | 27,5 | ||

| 0,40 | 1,5 | 2 | 19,7 | 15,5 |

| 2,5 | 23,9 | 18,8 | ||

| 3 | 27,8 | 21,9 | ||

| 3,5 | 31,5 | 24,7 | ||

| 4 | 34,8 | 27,3 | ||

| 2,0 | 2 | 21,7 | 17 | |

| 2,5 | 26,4 | 20,7 | ||

| 3 | 30,8 | 24,2 | ||

| 3,5 | 35 | 27,5 | ||

| 4 | 38,8 | 30,5 | ||

| 2,5 | 2 | 23,7 | 18,6 | |

| 2,5 | 28,9 | 22,7 | ||

| 3 | 33,8 | 26,6 | ||

| 3,5 | 38,5 | 30,2 | ||

| 4 | 42,8 | 33,6 | ||

| 3,0 | 2 | 25,7 | 20,2 | |

| 2,5 | 31,4 | 24,7 | ||

| 3 | 36,8 | 28,9 | ||

| 3,5 | 42 | 33 | ||

| 4 | 46,8 | 36,8 | ||

| 0,45 | 2,0 | 2 | 23,7 | 18,6 |

| 2,5 | 28,9 | 22,7 | ||

| 3 | 33,8 | 26,6 | ||

| 3,5 | 38,5 | 30,2 | ||

| 4 | 42,8 | 33,6 | ||

| 3,0 | 2 | 27,7 | 21,7 | |

| 2,5 | 33,9 | 26,6 | ||

| 3 | 39,8 | 31,3 | ||

| 3,5 | 45,5 | 35,7 | ||

| 4 | 50,8 | 39,9 | ||

| 0,50 | 2,5 | 2 | 27,7 | 21,7 |

| 2,5 | 33,9 | 26,6 | ||

| 3 | 39,8 | 31,3 | ||

| 3,5 | 45,5 | 35,7 | ||

| 4 | 50,8 | 39,9 | ||

| 3,0 | 2 | 29,7 | 23,2 | |

| 2,5 | 36,4 | 28,6 | ||

| 3 | 42,8 | 33,6 | ||

| 3,5 | 49 | 38,5 | ||

| 4 | 54,8 | 43 | ||

| 3,5 | 2 | 31,7 | 24,9 | |

| 2,5 | 38,9 | 30,9 | ||

| 3 | 45,8 | 36 | ||

| 3,5 | 52,5 | 41,2 | ||

| 4 | 58,8 | 46,2 | ||

| 4,0 | 2 | 33,7 | 26,5 | |

| 2,5 | 41,4 | 32,5 | ||

| 3 | 48,8 | 38,3 | ||

| 3,5 | 56 | 43,9 | ||

| 4 | 62,8 | 49,3 | ||

| 0,60 | 2,5 | 2,5 | 38,9 | 30,5 |

| 3 | 45,8 | 36 | ||

| 3,5 | 52,5 | 41,2 | ||

| 4 | 58,8 | 46,2 | ||

| 5 | 70,7 | 55,5 | ||

| 3,0 | 2,5 | 41,4 | 32,5 | |

| 3 | 48,8 | 38,3 | ||

| 3,5 | 56 | 43,9 | ||

| 4 | 62,8 | 49,3 | ||

| 5 | 75,7 | 59,4 | ||

| 4,0 | 3 | 54,8 | 43 | |

| 3,5 | 63 | 49,4 | ||

| 4 | 70,8 | 55,6 | ||

| 5 | 85,7 | 67,3 | ||

| 0,70 | 3,0 | 3 | 54,8 | 43 |

| 3,5 | 63 | 49,4 | ||

| 4 | 70,8 | 55,6 | ||

| 5 | 85,7 | 67,3 | ||

| 6 | 99,4 | 78 | ||

| 4,0 | 3 | 60,8 | 47,8 | |

| 3,5 | 70 | 54,9 | ||

| 4 | 78,8 | 61,9 | ||

| 5 | 95,7 | 75,1 | ||

| 6 | 11,4 | 87,5 | ||

| 5,0 | 3 | 66,8 | 52,5 | |

| 3,5 | 77 | 60,4 | ||

| 4 | 86,8 | 68,2 | ||

| 5 | 105,7 | 83 | ||

| 6 | 123,4 | 96,9 | ||

| 0,80 | 4,0 | 3 | 66,8 | 52,5 |

| 3,5 | 77 | 60,4 | ||

| 4 | 86,8 | 68,2 | ||

| 5 | 105,7 | 83 | ||

| 6 | 123,4 | 96,9 | ||

| 7 | 140 | 109,9 | ||

| 5,0 | 3

3,5 4 |

72,8 | 57,2 | |

| 84 | 65,9 | |||

| 94,8 | 74,4 | |||

| 6,0 | 3,5 | 91 | 71,4 | |

| 4 | 102,8 | 80,7 | ||

| 5 | 125,7 | 98,7 | ||

| 6 | 147,4 | 115,7 | ||

| 7 | 168 | 131,9 | ||

| 0,90 | 4,0 | 3,5 | 84 | 65,9 |

| 4 | 94,8 | 71,4 | ||

| 5 | 115,7 | 90,8 | ||

| 6 | 135,4 | 106,8 | ||

| 7 | 154 | 120,9 | ||

| 6,0 | 4 | 110,8 | 87 | |

| 5 | 135,7 | 106,5 | ||

| 6 | 159,4 | 125 | ||

| 7 | 182 | 142,9 | ||

| 1,0 | 4,0 | 4 | 102,8 | 80,7 |

| 5 | 125,7 | 98,7 | ||

| 6 | 147,4 | 115,7 | ||

| 7 | 168 | 131,9 | ||

| 5,0 | 4 | 110,8 | 87 | |

| 5 | 135,7 | 106,5 | ||

| 6 | 159,4 | 125,1 | ||

| 7 | 182 | 142,9 | ||

| 7,0 | 4 | 126,8 | 99,6 | |

| 5 | 155,7 | 122,2 | ||

| 6 | 183,4 | 144 | ||

| 7 | 210 | 164,8 | ||

| 1,10 | 4,0 | 4 | 110,8 | 87 |

| 5 | 135,7 | 106,5 | ||

| 6 | 159,4 | 125,1 | ||

| 7 | 182 | 142,9 | ||

| 5,0 | 4 | 118,8 | 93,3 | |

| 5 | 145,7 | 114,4 | ||

| 6 | 171,4 | 134,6 | ||

| 7 | 196 | 153,8 | ||

| 6,0 | 4 | 126,8 | 99,6 | |

| 5 | 155,7 | 122,2 | ||

| 6 | 183,4 | 144 | ||

| 7 | 210 | 164,8 | ||

| 1,20 | 4,0 | 5 | 145,7 | 114,4 |

| 6 | 171,4 | 134,6 | ||

| 7 | 196 | 153,8 | ||

| 8 | 219,4 | 172,2 | ||

| 6,0 | 5 | 165,7 | 130 | |

| 6 | 195,4 | 153,4 | ||

| 7 | 224 | 175,8 | ||

| 8 | 251,4 | 197,3 | ||

| 8,0 | 5 | 185,7 | 145,8 | |

| 6 | 219,4 | 172,2 | ||

| 7 | 252 | 197,8 | ||

| 8 | 283,4 | 222,5 | ||

| 1,40 | 6,0 | 5 | 185,7 | 145,8 |

| 6 | 219,4 | 172,2 | ||

| 7 | 252 | 197,8 | ||

| 8 | 283,4 | 222,5 | ||

| 8,0 | 5 | 205,7 | 161,5 | |

| 6 | 243,4 | 191,1 | ||

| 7 | 280 | 219,8 | ||

| 8 | 315,4 | 247,6 | ||

| 12,0 | 6 | 291,4 | 228,8 | |

| 7 | 336 | 263,7 | ||

| 8 | 379,4 | 297,8 | ||

| 9 | 421,7 | 331 | ||

| 1,50 | 8,0 | 6 | 255,4 | 200,5 |

| 7 | 294 | 230,8 | ||

| 8 | 331,4 | 260,1 | ||

| 9 | 367,7 | 288,6 | ||

| 10 | 402,8 | 316,2 | ||

| 10,0 | 6 | 279,4 | 219,3 | |

| 7 | 322 | 252,8 | ||

| 8 | 363,4 | 285,3 | ||

| 9 | 403,7 | 316,9 | ||

| 10 | 442,8 | 347,6 | ||

| 1,80 | 8,0 | 7 | 336 | 263,7 |

| 8 | 379,4 | 297,8 | ||

| 9 | 421,7 | 331 | ||

| 10 | 462,8 | 363,3 | ||

| 12 | 541,7 | 425,2 | ||

| 10,0 | 8 | 411,4 | 322,9 | |

| 9 | 457,7 | 359,3 | ||

| 10 | 502,8 | 394,7 | ||

| 12 | 589,7 | 462,9 | ||

| 1,50 | 8 | 491,4 | 385,7 | |

| 9 | 547,7 | 429,9 | ||

| 10 | 602,8 | 473,2 | ||

| 12 | 709,7 | 557,1 |

Pros of stainless products

Stainless steel profile products were widely used due to their long service life in comparison with analogues from other alloys. They are of high quality and light weight, which reduces the overall weight of the structure, do not need to be painted or used with other protective coatings.

Due to corrosion resistance, stainless steel pipe structures will serve both indoors and outdoors for equally long

Stainless steel does not enter into chemical reactions with other substances and is not able to change its own chemical composition. The production of rectangular pipes by 25 percent reduces the consumption of materials compared to round ones, and the presence of stiffeners (longitudinal) gives the structure additional strength.

Such products are perfectly welded, well amenable to mechanical processing and have the ability to be used in a significant temperature range. Corrosion-proof pipes are resistant to high pressure. They are usually used where good corrosion resistance is required. Assortment (of products allows you to choose the most suitable option.

How to bend stainless pipes

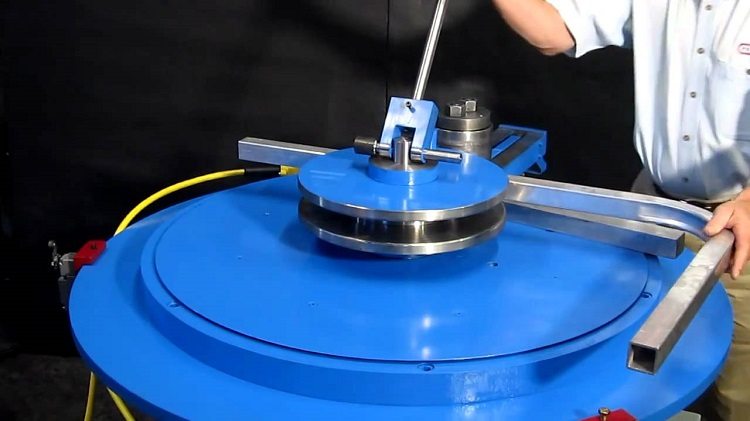

At home, it is often necessary to bend the pipe at a certain angle. To obtain the most accurate and high-quality result, it is better to use a pipe bender (profile bender). There are manual and mechanical designs of these tools.

A manual bender for bending stainless pipes includes a clamping element, a bed and a conveyor, consisting of connected rollers. The product can be moved by rotating the handle, and the pressure roller presses on the necessary face.

Note! In order to manually bend stainless steel pipes, both profile and round, it is necessary to make considerable efforts.

To work with a large batch of products, a manual pipe bender is ineffective. The mechanical apparatus allows bending stainless steel pipes without any physical effort, as it is equipped with an electric motor and hydraulic drive. The deformation scheme of the product is similar to the previous case.

Bending profile pipe stainless steel can be without a pipe bender by heating the structure. However, wrinkles may occur at the deformation site. One way to prevent them from occurring is to put sand inside the product. Previously, one of the ends is insulated with a wooden gag. After the entire internal cavity is filled, the second end also closes. Then the pipe is heated, bent and freed from sand and gag.

Profile pipes have advantageous technical, operational and aesthetic characteristics, as well as a wide range of products, which makes them popular and indispensable in many industries.