A canopy from a profile pipe in the courtyard of a private house or cottage can be built for a car, protecting malls, recreation areas, a swimming pool, etc. This design looks quite modern, easy, and also gives the site originality and uniqueness. Since the canopies should have sufficient rigidity and strength to withstand wind and other loads, then before installing them, a calculation is performed and a detailed drawing is made.

Content

Preparatory work before construction

Before the construction of the canopy is required:

- perform load calculations (if necessary);

- make a design drawing;

- to prepare the necessary tool for work;

- purchase materials.

There are several types of canopies from a profile pipe that you can assemble with your own hands, namely: single-pitched, two-pitched and arched. The type and shape of the structure, which will reflect the corresponding drawing, depend on the desire of the user and the amount of free space on the site.

Note! The fastest in terms of speed of construction and compact in terms of occupied area is the single-slope option.

Drawing and calculations of a canopy from a profile pipe can be done both with your own hands and using a special program. To maintain accuracy, it is better to be at the place of future placement of the structure.

An approximate calculation of the size of the structure is based on such initial data - the house is 6 x 9 m, in front of its free side there is a free area of 7 x 9 m. Let there be a canopy planned over the entire wall of the house (i.e. 9 m), the departure size is 6 m ( 1 m shorter than the site). Thus, the area of the canopy is 6 x 9 m.

The optimum height of the raised edge is 3.5 or 3.6 m, low - 2.4 m. The difference in the height of the slope allows you to calculate the angle of inclination - 12-13 degrees. Probable loads are determined by the wind and snow maps of the area. Based on these calculations, a detailed drawing of the canopy is made.

A single-pitched canopy resting on the wall of a house will require a minimum of materials and effort.

The main elements of the canopy and pipes for them

In the general case, the canopy as a spatial structure consists of the following elements:

- base plates and mortgages;

- arches;

- racks;

- farms;

- guides;

- roof;

- some additional elements, such as lighting and gutter systems.

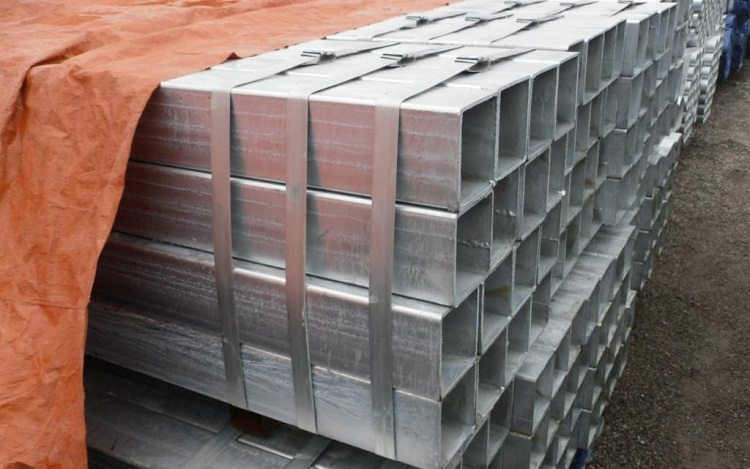

Poles or racks can be made of profile pipes, although ordinary products with a circular cross section can also be used. A significant drawback of the latter is a more complex configuration of the fastening of elements and bearing units.

Square shaped pipe ideal for mating structural parts at right angles. It is important to take into account that such a section is capable of providing equal rigidity in the transverse and longitudinal directions. When installing an arch, gable or single-pitch canopy from profile pipes, welding, bolted or threaded connections are used.

For the manufacture of trusses or runs, it is better to take pipes of a rectangular configuration, since they experience a significant transverse load, i.e., from top to bottom.At the same time, there are practically no forces along the axis.

Strength characteristics of pipes

To build a canopy and perform all the necessary calculations, it is important to determine the characteristics of the pipes. The corresponding values for products with square sections are given in the table.

Table 1

| Span length, m | 1 | 2 | 3 | 4 | 5 | 6 |

| Pipe parameters | Maximum load * 10 kg | |||||

| 40x40x2 | 70,9 | 17,3 | 7,2 | 3,5 | 1,6 | 0,5 |

| 40x40x3 | 94,9 | 23,1 | 9,6 | 4,6 | 2,1 | 0,6 |

| 50x50x2 | 116,5 | 28,6 | 12,0 | 6,1 | 3,1 | 1,4 |

| 50x50x3 | 161,5 | 39,6 | 16,7 | 8,4 | 4,3 | 1,9 |

| 60x60x2 | 171,4 | 42,2 | 18,0 | 9,3 | 5,0 | 2,6 |

| 60x60x3 | 239,3 | 58,9 | 25,0 | 12,9 | 6,9 | 3,5 |

| 80x80x3 | 449,2 | 111,0 | 47,8 | 25,2 | 14,4 | 8,2 |

| 100x100x3 | 747,3 | 185,1 | 80,3 | 43,0 | 25,3 | 15,2 |

| 100x100x4 | 921,7 | 228,3 | 99,0 | 52,9 | 31,0 | 18,5 |

| 120x120x4 | 1372,6 | 333,9 | 148,4 | 80,1 | 47,8 | 29,6 |

| 140x140x4 | 1906,2 | 473,6 | 206,9 | 112,5 | 67,9 | 42,9 |

The maximum loads for rectangular pipes (based on most of the sides) are given in the table.

table 2

| Span, meter | 1 | 2 | 3 | 4 | 5 | 6 |

| Pipe dimensions, mm | Maximum load value, * 10 kg | |||||

| 50x25x2 | 68,4 | 16,7 | 6,9 | 3,4 | 1,6 | 0,6 |

| 60x40x2 | 125,5 | 30,8 | 13,0 | 6,6 | 3,5 | 1,7 |

| 80x40x2 | 191,1 | 47,1 | 20,2 | 10,5 | 5,8 | 3,1 |

| 80x40x3 | 267,2 | 65,8 | 28,1 | 14,6 | 8,1 | 4,3 |

| 80x60x3 | 358,3 | 88,4 | 38,0 | 19,9 | 11,2 | 6,2 |

| 100x450x4 | 548,9 | 135,7 | 58,5 | 30,9 | 17,6 | 10,1 |

| 120x80x3 | 785,4 | 194,7 | 84,6 | 45,5 | 26,9 | 16,4 |

Calculation of structural strut parameters

To select the parameters of the racks, a preliminary calculation of the loads is made and a drawing is made.

Note! The width and wall thickness depend on the length of the pipe and affect its rigidity. For example, you can use a thin-walled product with a large shelf width or thicker with a smaller cross-sectional value.

The supports must be placed at an equal distance so that the load on them is uniform, and the entire structure is stable

It is important to take into account that the vertical load perceived by the stand from the canopy overlap is small, therefore even a thin profile pipe is able to withstand it without deformation. The drawing of the canopy from the profile pipes should include the exact dimensions of all the posts.

For a design of medium dimensions, products with a cross section of 50 to 100 millimeters are suitable. In the case of their more frequent location, the pipe size can be reduced. If a single-pitch canopy has four supports, then it is better to use products of a larger cross section.

Farms as structural elements

Farms belong to additional connecting elements of the canopy design, giving it strength and stability. For them it is necessary to make a separate drawing.

The standards provide for the calculation of trusses from pipes for awnings, the angle of inclination of which is from 6 degrees. It is better to push at least 8 degrees. This is because a small slope value is prone to snow accumulation in winter on the roof surface. The optimal values are 15-20 degrees. Such a pest is well suited for roofing made of plastic, corrugated board, roofing material, polycarbonate, slate and other materials.

There are such forms of similar elements:

- triangular;

- trapezoidal;

- broken;

- rectangular;

- arched.

Inside the farm, you can install additional runs, racks, struts and braces. Their support is carried out in a combined way or pinched by one of the ends. The drawing should include not only the dimensions, but also the quantity, type of required materials. Since trusses are assembled from hollow elements, the weight of the carcass frame will be relatively small. In the horizontal plane, they are fastened together by cross-shaped bonds made of profile metal with a small cross section.

The following is the installation of a battens from a beam having a height of 50 mm. It is intended for fixing roofing. The beam must be pre-saturated with an antiseptic compound or painted with a special paint to prevent rotting of the wood.

Construction stages

The main stages of the construction of the canopy include:

- foundation preparation;

- cutting of all materials specified in the design drawing;

- farm manufacturing;

- assembly of the side walls of the canopy;

- connection of roofing trusses with finished sections;

- checking the correctness of the assembled structure using tape measure and level;

- installation and fastening of a canopy on the prepared site and reliable fastening;

- processing of metal surfaces with protective agents;

- preparation of material for roof sheathing, its installation and fastening;

- trimming the excess parts of the roofing material;

- improvement of the nearby territory.

At the stage of preparation of the foundation, soil is removed in those places where it is planned to find supporting pillars. A layer of rubble is laid out at the bottom of each of the pits. Next, a mortgage is installed that has welded bolts to secure the racks. You can also use reinforcement to give the canopy extra strength. Cement mortar is poured into the remaining space. The side walls are assembled by connecting the connecting trusses and support columns in the selected manner.

Note! If there is a one-piece canopy, then the side sections are installed on the foundation before mounting the roof trusses.

It is important to monitor the compliance of the design with the finished drawing and the verticality of the elements at all stages of arranging the canopy. When preparing the material for cladding, it is better to cut sheets with a small margin. This will eliminate possible measurement errors.

The basis for the canopy can be a platform flooded with concrete or a ready-made reinforced concrete slab

Selection of necessary materials and tools

Since the main requirements for profile pipes are stability and strength, it is necessary to take products with a minimum size of 80x80 millimeters for the supporting elements of the canopy. For additional details, a cross section of 40x20 mm is optimal.

The calculation of the amount of roofing material is based on the calculation of the surface area that will be closed, with an increase in the obtained indicator by 5%. Fastening is usually carried out by roofing bolts with gaskets. The canopy can be assembled using one of the following methods:

- welding (requires electrodes and a welding machine);

- using threaded connections (fixing bolts and metal angles are required);

- using special clamps.

It is desirable to paint the carcass frame to protect it from corrosion. In addition to materials, you will need such a tool for work: a measuring tape, a level to control the verticality of the structure, a screwdriver, a grinder for cutting pipes, a shovel for earthwork. For safety reasons, it is best to carry out the entire assembly with gloves to protect your hands.

The design of the canopy can be made independently from profile pipes or buy an already finished one. A canopy with your own hands will be much cheaper and will meet all the requirements if you carefully follow the methodology of its construction.