Steel square pipe recently became very popular in the construction industry. It is simply indispensable for the construction of sports fields, commercial and residential buildings. It is used even for the construction of television towers. Such popularity is due to the undoubted advantages of the product. However, it also has its own characteristics, which must be familiarized with before purchase and installation.

A square steel pipe is a universal product that is used in the manufacture of a wide variety of structures and structures

Content

What is it like

Steel square pipes are used in the construction and repair of buildings of various types and purposes. In addition, they make fences, frames, gates, floors; they also serve as an element of the supporting structures of structures and decorative details of the interior. If you need the effect of forged parts - they are also perfect for this purpose.

Often this equipment is used as a replacement for a metal bar. What are its advantages compared to it? Mostly in value. The profile pipe is hollow inside, for its manufacture much less raw material is consumed, which means its cost will be much lower.

In addition, it is much easier to bend, again due to the fact that there is a cavity inside it. For this, a special tool is used - a pipe bender. It exists in different forms depending on the principle of action, level of complexity and scope of work. In addition, the parameters of the pipe itself have values for the choice of a pipe bender.

Good to know! In strength, such a pipe is almost not inferior to a bar. This is ensured by the design: such a pipe has the correct shape and stiffeners, thanks to which it has special strength and is able to withstand significant loads.

Designs of square pipes are highly durable, so these products are used in the construction of residential and public buildings

The pipe is easier and cheaper to transport, as it is manufactured in standard sizes and has a relatively low weight.

Production process and its features

In order to better understand the quality of the product and subsequently choose the one that will last you a long time, while maintaining strength and all other necessary operational characteristics, you should study the product as best as possible. For this, it will not be amiss to get acquainted with the production process. This is important, because the quality of the product is determined by technology and its compliance.

A square steel pipe (in assortment) is made of steel of a special composition (often carbon steel), which has all the necessary characteristics to ensure functional, strength characteristics, and also to guarantee a long service life. In addition, stainless steel, copper or brass can be used in the manufacturing process.

There are two main methods for manufacturing such equipment.

Production according to the first method begins with the procurement - the so-called strip. Pipes of the design section with a round cut are made of it. After that, the details go through the forming stage in a special compartment with rolls - so they get their final shape.

At the final stage, square steel pipes are tested for strength, checked for damage and checked that the finished goods comply with GOST. Then the pipes are heat treated to relieve possible mechanical stress, and this is where the production ends.

However, there is a cheaper and simpler method of manufacturing - welding of a tape profile. Pipes made in this way have a slightly lower strength (its level is 95% -97%).

The manufacturing procedure consists of several stages:

- cutting steel sheet into strips;

- the formation of stripes of tape;

- the formation of profile blanks in a special compartment with rolls;

- pipe welding in an inert gas environment (for this, the workpiece is placed in a specially equipped chamber).

To ensure a higher level of strength, special stiffeners are present inside the pipes.

Assortment of steel supporting structures

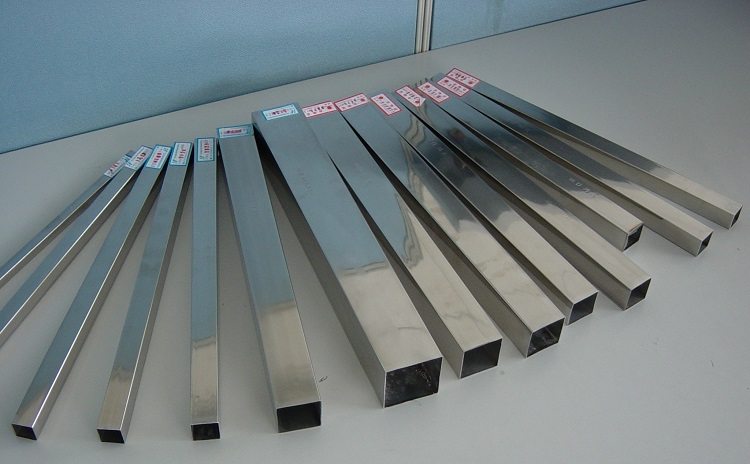

At the moment, there is a large assortment of steel profile products. It is classified by such factors as the length of the pipe itself (varies in the range from 1 to 12 meters, most often up to 10 meters, however, many manufacturers make pipes of certain lengths to order from a client or cut ready-made pipes), profile parameters, its type, section diameter .

Any type of pipe is manufactured according to GOST, but at the request of the customer non-standard options are possible.

In addition, there are different brands of equipment, determined, however, by the same state standards (GOSTs).

Depending on the type of profile, there are pipes of square, oval and rectangular cross-section. Plus rectangular and square, in comparison with oval - convenience when laying on flat surfaces: they do not roll down, and they are easier to fix). They are brass, copper and steel depending on the material; and besides, they are distributed in accordance with the purposes of use.

Good to know! For relatively lightweight structures that do not require heavy weight, thin-walled equipment (the so-called furniture profile pipes) is used. Such products often serve as decoration.

For more massive structures (floor beams, supporting elements during construction, etc.), building pipes are used.

The assortment of profile parts also includes flat oval. They are also called arched profiles. These are more complex parts, the production of which is more laborious and time consuming, but pays off with additional technical advantages.

General metal products - a universal type of parts. It is resistant to damage, hardy, able to withstand heavy weight and significant loads, but their surface quality is somewhat inferior to other types.

The strength characteristics of square pipes are so high that they are used for mounting load-bearing structures

Product Benefits and Features

The popularity of such equipment is due to the presence of significant advantages. Among them:

- Universality. This equipment is used in almost all sectors of the construction industry and in repair work. The assortment of square steel pipes is so wide that they are used everywhere: from massive load-bearing structures to decorative elements. The use of such products as decorative and loading elements is very common. As an example - legs of a toll or a chair, a railing of stairs or a grate of fireplaces, a visible frame of furniture and much more.

- Lightness and plasticity. These qualities make it easy to bend the product. To do this, you only need a pipe bender. It can be manual, hydraulic or electric - choose depending on the amount of work, the level of tasks and your own budget.

- Acceptable price.Metal is a material that is economically advantageous in terms of financial investments. Its cost pays off with efficiency and long service life.

- Reliability. Structures using such pipes are able to withstand heavy loads over a long period of time.

- Good assortment. You can find and use a pipe of any parameters and use it in the most inaccessible places of an object or room.

- Easy installation. A simple and convenient form, as well as a monolithic structure, facilitate the installation and transportation.

- Durability. Such parts can last for several decades with proper installation and high quality.

- Resistant to damage. Despite the fact that the main drawback of metal equipment is its tendency to develop corrosion processes, this problem is currently not relevant for steel and galvanized pipes.

- Resistance to adverse effects of temperatures. Such equipment functions normally, maintaining all the necessary technical characteristics even at extremely low and high temperatures.

- They serve as an excellent replacement for reinforcing parts. And they are even used in the construction of towers and bridges.

When mounting structures from a square pipe, welding is most often used, and this can cause difficulties for an inexperienced installer

In addition to a large number of advantages, square steel pipes in a large assortment have their own characteristics and disadvantages. For example, they do not pass hydraulic tests; therefore, they cannot be used for transportation of volatile substances. However, some manufacturers manage to eliminate this drawback, making the product even more universal. And in order to achieve a strong connection of such pipes, you need to use a welding machine. This is a specific equipment that not every master can handle.

Assembly and handling tips

If you decide to use a profile pipe in the repair or construction, then you should take into account the main points that are relevant when conducting these works:

- When constructing buildings and awnings in the open, it is better to use already painted pipes, or coated with a special protective layer (anti-corrosion spraying, zinc coating). In addition, stainless steel parts are perfect. You can save a lot by painting the pipes yourself. Even if you spend money on expensive paint, the savings will reach 30%;

- if necessary, you can connect the pipe sections to each other using self-tapping screws and nuts. Use a drill to make holes;

- as regards special equipment (for welding or pipe bending), then it is not always advisable to acquire it. If you need to give a certain shape to a few small details, or if your structure is small, it makes sense to contact a master who will do it himself using his own pipe bender. If the volume of work is impressive, then it is better to get your own device. The same applies to welding.

Helpful advice! It is better to purchase products in large retail outlets, because in addition to good quality and excellent service, they can sometimes offer the pipe cutting and bending service as a bonus for the buyer or provide such a service at a reasonable price.

In general, the installation of structures from square pipes is not a complicated procedure. However, like any repair and construction work, it requires care, accuracy and strict adherence to the rules.