The first impression of a private estate is a solid fence and a metal gate with a wicket. Doors from a profile pipe are gradually made with your own hands, if you have elementary skills in working with metal and welding. It is easy to decorate an ordinary lattice and a framework with a decorative finish - forging, overhead elements or galvanized sheet to hide from prying eyes what is happening behind the gate. They are made sliding or swinging, and even better - opening remotely in automatic mode.

Content

What is important to know about self-made doors?

Independently weld the gates from profile pipes at home, any home master can have a tool and minimal experience with the welding machine. If there is no welding, these services can be ordered by an experienced welder, and do the rest of the work yourself with your own hands.

The final result largely depends on several aspects:

- a good choice of gate design;

- competently made drawing (sketch);

- high-quality metal;

- good fittings.

Attention! Strictly vertically installed support posts are very important, which eliminates distortions and spontaneous opening of the gate under its own weight.

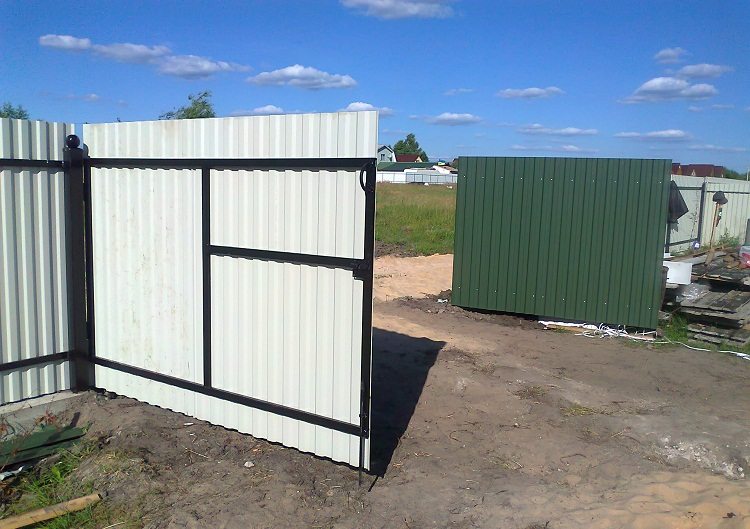

Homemade gates on a metal frame are made for the garage and at the entrance to the courtyard. Ideally, they should be implemented in a single key. Even a simple design, executed carefully, will be in harmony when the two gates are similar and painted with the same paint. Even if some gates are sliding, others are oar, but with a similar finish, it looks aesthetically pleasing. Although they are structurally different, when closed, they look the same.

Sliding gates can be installed at the entrance to the courtyard if there is not enough space for swinging

Making gates from shaped pipes with your own hands is a laborious process involving the transportation, cutting and welding of metal. Separately, you will have to deal with digging up pillars. An important point is that it is better to do the entrance gate with a gate that closes independently, it will have to be used more often than the gate. Do not do everything in a hurry, primitively - the gates should serve for a long time.

How to choose materials for metal gates?

The quality of materials and the competent choice of a profile pipe of the desired section is the key to success. Some masters act recklessly, make a frame of metal, which remains from other construction and installation works. As a result, self-made gates turn out to be too heavy or skewed, unattractive.

Advice! The metal for the frame must comply with all technical parameters, of the metal residues it is permissible to perform only decoration, molding and lintels.

A blank of rectangular or square shape is the best option for the production of a door frame from a profile pipe and other frame products at home. They are produced according to technical standards from carbon steel of various grades, galvanized steel or stainless steel.

Stainless steel products are quite light, expensive and durable.Such a metal is not suitable for a heavy load, but for decorating a gate or a gate with your own hands - this is the best choice.

Profiled steel is available in different forms:

- welded pipes and seamless;

- hot rolled and cold rolled.

Solid or seamless pipes are designed for the highest load. They are used for the frame, supports and frame structures.

Inexpensive blanks are quite suitable for the independent manufacture of swing gates (or sliding) from a profile pipe:

- under the supports, a profile of 100x100 mm is recommended;

- a profile 40 × 40 or 50x50 mm is recommended for a frame or frame;

- a metal rod or pipe cut 40x20 mm is suitable for lintels or gratings.

Preparatory stage

To begin with, we determine the type of gate, they can be done:

- openwork;

- trellised;

- forged;

- with a covering from a professional leaf, a tree or a siding.

Advice! Solid gates are made to hide what is happening in the yard from outsiders. If there is a desire to demonstrate the beauty of a cozy courtyard to passers-by, then it is better to make openwork gates with elegant forging with your own hands.

If there is little experience, then it’s easier to make swing gates with your own hands - from a profile cut into drawings and a metal rod. A good drawing is needed to accurately calculate the total amount of material used and the length of each workpiece. Automatic control should also be planned in the first stage and summed up in costs.

The size of the gate should be convenient for daily use of the car. The minimum opening of the gate is from 3m, so that the car easily passes through the gate and leaves the street. The height of the frame is at least 1.6 m. The width of the gate should coincide with the level of the gate at the lowest point, if the tip is made in the form of a crown. The gate should be convenient for the passage of a person of any complexion - from 0.75m to 1m.

Often welding of doors from a profile pipe is performed as part of a previously installed fence. The general sketch allows in the smallest details to present the final result. Therefore, whatever the choice of the finished illustration, you will have to draw it to adapt to your court.

All purchased metal is previewed in order to reject the profile with defects - during cutting it will fit into short and auxiliary parts. Pipes with signs of corrosion must be cleaned with sandpaper or wire brush before cutting.

Attention! Swing gates are a paired product, therefore, for symmetry, all parts are cut in pairs, observing dimensions up to a millimeter. Then you can start cutting blanks for the gate.

Details for the finish are prepared with their own hands separately. Elements for decoration in the form of openwork forging can be purchased ready-made - in specialized departments of building supermarkets or in a blacksmith workshop.

After cutting the blanks to the gates from the profile pipe with your own hands, you will need to rent a welding machine or hire a specialist. It costs a lot. Therefore, it is important to properly organize the preliminary preparation stage so that the leased equipment does not stand idle for several days. In any case, the independent manufacture of metal gates will cost several times less than buying a finished product with installation. Moreover, it is pleasant when a product assembled by one's own hands attracts the enthusiastic looks of neighbors.

Second stage: installation of supports

An important condition is the absolute verticality of the supports, so that the gates can not tilt or spontaneously open / close.

The quality of the installation of rack supports for gates from a profile pipe determines their durability and flawless operation.Columns should be dug deep into the ground and carefully concreted, while not being submerged under the weight of the entire structure.

To install the base of the gate, you need to make a marking for 3 holes - 2 for the gate leaves and 1 for the gate (if planned). Of course, the gate can be mounted on the same column as one half of the gate, but this will create an additional load. Under the supports dig deep rounded pits with a diameter of up to half a meter and a depth of not more than 1 m. The bottom of the potholes is leveled and covered with gravel with sand, tamping well.

The columns are placed strictly vertically in the pit, sprinkling with rubble or rubble stone under the concrete solution. After a small layer, the vertical is verified and finally poured with concrete to the top. Get a kind of foundation under the frame.

Attention! Do not hang gates from the profile pipe onto this structure until the mortar has completely hardened. Depending on the temperature and quality of the cement mixture, this will require 3-5 days in summer weather. If the strength of mounting the base of the gate is obvious, go on to do-it-yourself assembly of the main parts.

Third stage: assembly of the gate leaves

The main task when assembling with your own hands is to weld a reliable frame for swing gates from profile pipes.

The overall aesthetics will depend on the accuracy of the layout and the observance of the distance between the metal segments forming equal intervals. The second aspect is the aesthetic welding seams of the frame without coarse sag with the processing of burrs. This will ensure safety when using the gate and gate.

It is better to work with the welding machine in the open air, providing it with power. It is imperative to observe safety precautions - in overalls and a protective mask. There should not be any flammable objects on the welding site that could be exposed to a spark or scale.

When the frame construction of the handle is ready, the remaining structural elements are welded to the frame. Ready-made gates must be mounted on hinges, and the functionality and reliability of the entire structure depends on the quality of their welding to poles. Well-installed hinges should not creak or jam. When the hinges are ready, they proceed to hanging all the parts - gates and gate leaves.

The final stage is degreasing, priming and staining. Do-it-yourself sliding or sliding gates do about the same, but guides and rollers are needed to ensure the movement of the wings. These parts are also mounted strictly according to the level, without distortions otherwise the gates simply will not open.