Profile pipes today are a very popular type of metal and are used in various fields of human activity. Profiled pipes are divided by purpose, and, depending on this parameter, can have a different shape, and also differ in other important parameters. The weight of a profile pipe is a characteristic that affects its cost. In order to correctly calculate the weight of a linear meter of a profile pipe, there are several ways.

You can calculate the weight of profile pipes in different ways, but for this you need to know some parameters of these products

Content

Why do you need to know how much a profile pipe weighs?

Calculation of the weight of professional pipes is necessary primarily to determine the value of this product. The calculation of this parameter affects not only the price, although this is the root cause. The calculation of this indicator is also necessary in order to determine the operating conditions of the pipes.

Important! To calculate the weight of 1 pm of the profile pipe, you need to know the initial amount of material spent on the manufacture of the product.

The profiled parts used in the construction industry need to be determined by mass. This is necessary so that the design engineer can calculate the load that the structure of these products is able to withstand, as well as the load that the structure of profiled metal itself will create. This is necessary in order to properly design and execute the frame structure, which will minimize the threat of its destruction.

The physicomechanical characteristics of the profile pipes depend on their mass, therefore, when designing a particular construction, the engineer pays attention to the features of the frame and selects the best professional pipes for installation. The more complex the design, the more difficult it is to calculate the optimal weight of the profiles and other characteristics.

The dimensions and weight of the profile pipes are necessary parameters that are taken into account and affect the storage and transportation of this product. These characteristics are necessary for calculation during transportation - they help to know how many meters in a ton of shaped pipes. Volumetric calculations are preferably performed according to the formulas, since the accuracy of the tables is usually lower.

The total mass of the whole metal structure depends on the weight of the blanks used in construction

What determines the weight of the pipe?

As already mentioned above, in order to calculate the weight of profiled pipes, you need to know the amount of source material that was taken for their manufacture. This rule applies to core products. The weight of 1 meter of a profile pipe is determined by several parameters that are worth paying attention to:

- the form;

- geometric data;

- specific gravity.

First of all, its shape affects the weight of 1 m of the pipe. To date, the most popular products that relate to this type of metal rolling are the following pipes:

- square;

- rectangular.

The above products are used mainly in the construction industry, for the organization of frame structures. They are also in demand in the automotive industry. Due to the smooth planes, their connection is very simple and convenient.

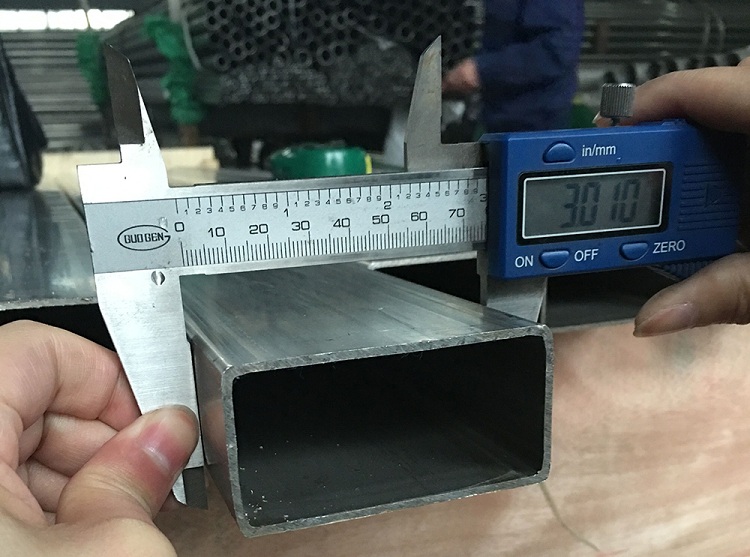

To calculate the weight of the pipe, you need to know the cross-sectional dimensions and wall thickness

Helpful information! The material from which such parts are made may be different. However, all profile pipes that have a square and rectangular cross-section are easily articulated with each other.

The specific gravity of a meter of pipe can be calculated using several methods. This indicator is easy to determine using formulas. Thanks to this, it is possible to quickly calculate the mass of the profile pipe, which is necessary to obtain operational information for the construction project.

Geometric data

In order to calculate the amount of source material spent on pipe production, you need to know the following important product specifications:

- profile width;

- profile height;

- wall thickness of the profile product.

Accordingly, there is a certain dependence, which is unchanged, namely, the greater the value of the above indicators, the more the profile pipe weighs. There is one more parameter that practically does not affect the weight of a rectangular or square pipe, but for ovoid (oval) products this characteristic is decisive. This parameter is the strength coefficient during bending.

If all the necessary geometric data are known, it is not difficult to calculate the volume that was used to make 1 m of these products. To calculate the weight of a rectangular shaped pipe or square part, simple formulas will be required by which this characteristic can be easily determined.

The weight of the pipes depends on their shape, which is also taken into account in the calculations

There are ready-made tables on the Internet, using which you can easily find the finished theoretical weight of the required product.

Specific gravity of steel

This parameter is the ratio of the weight of the material, which is necessary in order to fill the volume of one meter or more (depending on the nature of the calculations). The specific gravity of the material is measured in the following units:

- according to the absolute physical system of units (GHS) - 1 g / cm³;

- according to the international system of units (SI) - 1 kg / m³.

The specific gravity index is directly proportional to the weight of 1 meter of the profile pipe. That is, the higher this indicator, the correspondingly, the greater will be the weight of a running meter of the profile pipe. For steel products, the specific gravity, as a rule, ranges from 7500 to 7800 kg / m³, depending on the composition of the alloy. Or rather - from the ratio of various elements in the alloy. The following elements are included in the steel alloy:

- iron;

- carbon;

- cast iron.

For example, the more carbon is consumed in the production of a steel pipe, the less will be its mass, and the lower will be its strength characteristics.

What methods are used to determine the mass of a profile pipe?

As a rule, products that have a rectangular and square shape, combine two very important characteristics:

- affordable cost;

- high strength characteristics.

The most frequently purchased and operated products are pipes of this size:

- 20x40;

- 40x40;

- 100x100.

In order to calculate the weight of a meter of a professional pipe (for example, with dimensions of 100x100), it is recommended to use one of the methods for finding this parameter. There are several such methods, and all of them will be discussed below.

Note! Unlike conventional pipes, profile metal products from different suppliers can have different weights even if they are of the same size (cross section and wall thickness). This is due to the fact that profile products in accordance with certain tolerance limits. Even the dimensions indicated in the GOST tables may differ from the actual data.

Therefore, it is recommended to conduct an individual calculation for higher accuracy, which will be required to find other, no less important, parameters necessary for the correct implementation of the construction project. Consider the three main methods that are used to determine the weight of rectangular and square shaped pipes:

- ready-made tables that can be found on the Internet or in specialized books;

- formulas;

- computer programs.

To determine the mass of rectangular and square profile parts, it is necessary to use a special formula. For round pipes, individual formulas are used. Consider the formula by which everyone can calculate the weight of 1 meter of a square pipe, as well as a rectangular one:

1 p m details = S x 2 x (A + B) x ρ

where S is an indicator of the wall thickness of the product, which is calculated in meters; A and B - indicators of the lengths of the sides of the core product, which are calculated in meters; ρ is the density coefficient of a particular alloy. This formula can be useful in situations where it is not possible to see the weight of the profiled part according to the finished table or if the most accurate calculation of products for a complex construction project is needed.

You can calculate the weight of a profile steel pipe in another way - using special computer programs. A computer program calculates the mass of not only rectangular and square products, but also round, as well as any other shape. To determine the mass of the product through a special program, it is necessary to enter the initial data (dimensions of the profile pipes) into it. Consider the list of parameters that will be required for this:

- part length;

- sectional option;

- profile wall thickness.

In addition, the program will need to select the material from which the part is made.