A large number of accidents of water mains during the winter season is due to the fact that the water in them freezes. For this reason water pipe insulation is a very urgent problem in our country. After all, frost is merciless to any material from which a water supply pipeline can be made, starting from high-quality galvanized steel pipes and ending with metal-plastic products from leading manufacturers.

Thermal insulation for pipes is necessary to prevent freezing of the working medium of the pipeline, heat loss and condensation

Content

Goals and objects of thermal insulation

Thermal insulation means materials, as well as methods designed to ensure that the surface of the water supply pipes does not contact the cold ambient air. The materialization of this definition at the industrial level has led to the appearance of many varieties of products that make it possible to realize the above requirement.

For the manufacture of thermal insulation materials with a very low coefficient of thermal conductivity are used. They are called heat insulators. If thermal insulation is designed to retain heat inside the insulated object, such materials are called “heaters”. Thermal insulators are characterized by high porosity and heterogeneity of the structure.

By means of thermal insulation of water supply pipes, the loads on the walls of engineering communications are reduced, as well as the degree of its contact with the environment, and, consequently, the liquid circulating along the highway. We are talking mainly about freezing temperatures. This is achieved in accordance with GOSTs and other regulatory documents in force in our country. It is in them that the rules for creating a thermally insulating environment for technological purposes are regulated. According to experts, the best choice is protection with gas or vacuum.

Features Lower energy costs

The most affordable and simple is considered to be a heater for water pipes (read, a heat insulator for water supply), created on the basis of fibrous materials with a special structure, due to which the retention of thermal air masses is carried out. Here, the heat loss in the carrier is minimal, and it is maintained in a state that eliminates the possibility of freezing.

An inconvenient, difficult problem is the pipeline system with stagnant water. When the liquid does not circulate along the production lines, its temperature, although very slowly, but inevitably drops. Ultimately, water can begin to crystallize. In this case, you can:

- increase pressure in communication;

- perform a fluid discharge;

- force to heat.

Important! The last option, based on fire safety requirements, is carried out in accordance with existing projects and acts.

Today, thermal insulation for pipes for cold and hot water supply is very relevant and important.Ignoring the requirements of GOSTs, as well as other regulatory documents, can cause breakdowns in the centralized water supply system in winter. All currently operating pipelines are laid both in the ground and above its surface. In contact with the air masses, the pipes give off heat, which causes a decrease in the temperature of the working medium. The lack of necessary coverage will cause significant budget losses and reduce the quality of services provided to the population.

Monitoring compliance of thermal insulation with the requirements is the main responsibility of employees of special state bodies. An ordinary citizen should also not turn a blind eye to obvious omissions in this matter. For example, he may be interested in why a particular section of the pipeline is not covered by a heat insulator and other facts testifying to the negligent attitude of officials to the performance of their duties and their squandering.

Thermal Insulation Requirements

When purchasing heat-insulating material, you need to stop your choice on one that is characterized by certain properties.

These properties are as follows:

- simplicity of laying. This will allow you to save on the purchase of the necessary tools and equipment, as well as the payment for specialist services;

- minimal moisture absorption. To do this, you will need to find out the hygroscopicity coefficient of the heat insulator in question. The greater its value, the more moisture the material absorbs. And this causes a decrease in its heat-insulating characteristics.;

- minimum coefficient of thermal conductivity;

- wide operating temperature range. A material with this property can be used both at very low and very high temperatures;

- fire safety. This issue is especially relevant for those main water supply systems in which there are open areas;

- durability. The annual repairs or replacement of thermal insulation will be tedious and overhead;

- chemical inertness. The coating must not react chemically with the pipe or with the atmosphere.

Next, we dwell on the types of pipe insulation, their main advantages and differences.

Styrofoam

To all those who studied the regulatory documents, experts recommend paying attention to foam-based thermal insulation. Of the advantages of this material, it is worth highlighting:

- quick and easy installation;

- low coefficient of thermal conductivity;

- minimum cost;

- even one layer has excellent thermal insulation qualities;

- design feature allows you to collect thermal insulation without the use of special tools;

- due to the fact that the foam does not absorb moisture, it is allowed not to use additional waterproofing components;

- the material is inert to various biological and chemical elements;

- due to its resistance to temperature changes, it is suitable for thermal insulation of systems, both hot and cold water supply;

- light weight. Therefore, the load on the pipeline is minimal.

Important! Polyfoam is highly flammable, and is characterized by increased flammability. When burned, it releases dangerous and harmful chemicals. Therefore, during the operation of the insulation made of foam plastic, it is necessary to strictly observe the fire safety rules.

Mineral wool and fiberglass

It is necessary to choose heat-insulating materials taking into account their composition, the diameter of the treated area, as well as the installation method. The wrong approach can lead to a significant deterioration in the quality of the functioning of engineering communications, a decrease in its productivity and heat loss.

Many home masters give preference to mineral wool due to the fact that it can heat-insulate trunk sections of any type. Another important factor is the reasonable price of this material. These properties offset such a disadvantage of mineral wool as the high complexity of the work.

The main points of the method of thermal insulation with mineral wool are indicated in the relevant regulatory documents. Consider them in more detail.

First, the minvata and fiberglass roll is cut into rectangles with sides of 15 and 20 cm. Then, the resulting pieces are sequentially wrapped around the pipes. Fix the mineral component without undue compaction and squeezing. After the thermal insulation layer is formed, it must be protected with fiberglass. This method is used for large diameter outdoor pipelines. It is impractical and inconvenient to insulate pipes with a cross section of less than an inch of mineral wool and fiberglass due to the specific physical properties of these materials.

Polyurethane foam (PPU) shell

Using this material, you can insulate almost all types of utilities, even if the pipes are laid in the open. The use of PPU shell reduces heat loss by 95%. Polyurethane foam is highly resistant to most aggressive chemicals, including household chemicals. Having come into contact with chemicals, it does not lose its properties and does not decompose. Among the other advantages of the shell made of polyurethane foam, it is worth highlighting the following features:

- significant rigidity and resistance to mechanical damage. This property is especially true for pipelines that are located on the street;

- when in contact with water, the material does not deteriorate and does not absorb it;

- ability to work in a wide range of temperatures. This characteristic allows the use of PPU shell for thermal insulation of the pipeline of any type;

- polyurethane foam will not suffer from attacks of rodents, since this material is not in their taste.

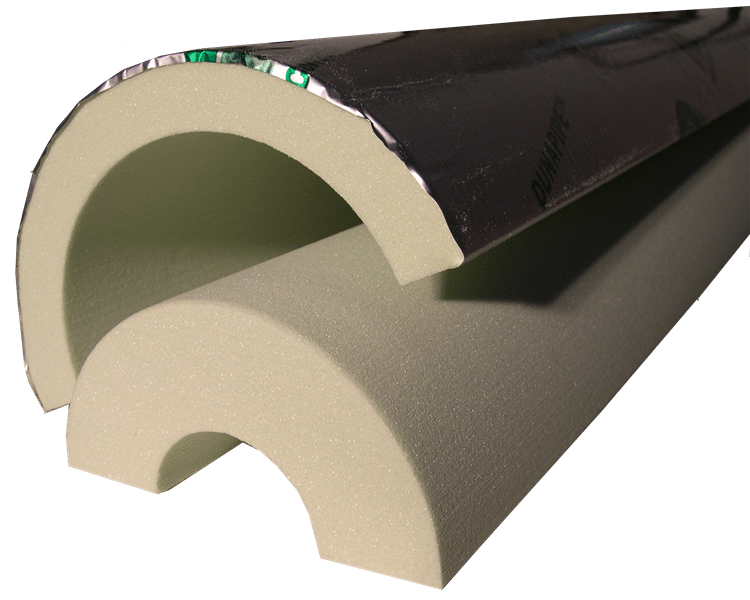

Modern industry has launched the production of several types of PPU shells. Some of them have a layer of additional coating of special foil, while others are made entirely of polyurethane foam.

Such products look like a hollow half cylinder of certain sizes. This form suggests that for the insulation of a separate section of the water supply, 2 shell samples will be required.

Good to know! In addition to standard half-cylinders, a shell for insulating pipe bends and turns is also on sale.

The height of the half-cylinders (in this context, the word length is more suitable) is different, but most often you can find samples with the value of this parameter equal to 1 meter. They are easy to cut. Shell service life reaches 50 years. In addition, this heat insulator can be reinstalled, of course, while its thermal insulation characteristics will not be affected.

Liquid protection of a water supply system with two-component polyurethane foam

A two-component foam is used in conjunction with a casing that acts as a protective element. Since its operation is carried out on the street, in order to protect it from corrosion, stainless steel or galvanized iron is used to manufacture the casing base. This leads to an increase in the cost of work performed.

Having high thermal insulation performance, such a design has been widely used in the construction of large diameter utility networks. But the performance of work involves significant labor costs. In addition, regulatory documents regulate the use of thermal insulation of this type only on the street.The reason is that the material can be harmful to human health.

Network processing using a liquid two-component polyurethane sealant begins with the installation and centering of the protective metal casing relative to the pipe body. Then, in turn, the main and auxiliary element on a polyurethane basis is laid in the casing. When they come into contact, a chemical reaction accompanied by foaming will begin, as a result of which all the free space will be filled with a dense composition. The selection of the dosage of the material is very critical. Excess will lead to its excessive consumption and unnecessary additional costs, and a disadvantage to poor-quality pipe insulation.

Timely thermal insulation works can guarantee the owner of a private house peace of mind, since utilities will be reliably protected from the effects of negative natural factors.