Almost every owner of a private house or land faced the problem of freezing water pipes. It is not always possible to lay the water supply system below the level of soil freezing, and pipe freezing can have completely different reasons: winter is too cold for a given region, mistakes made during installation. You can resolve this issue with installation of heating cable for water supply: Even a novice electrician will cope with this procedure without much difficulty.

Installing a heating cable is an effective solution to the problem of freezing water supply in winter

Content

- 1 How does a heating cable for water supply work?

- 2 Choosing a self-regulating heating cable for water supply

- 3 Installation of a heating cable for water supply: insulation method from the outside

- 4 Installation of heating water pipes with a cable inside

- 5 Is it possible to make a heating cable for a water pipe with your own hands?

How does a heating cable for water supply work?

The degree of need for laying the cable for heating the water supply is preferably foreseen. It is not necessary to arrange a “strength test” already installed in the water supply system: wait for the first severe frosts, and only then make a decision about heating the pipe. A timely warming procedure will save both monetary and temporary resources.

The principle of operation of the cable for heating the water supply is simple: a self-regulating wire is laid in the pipeline section or along its entire length, then it is connected to the electric network. As a result of this, the required area is heated. There are only two mounting methods - the cord can be attached to the outside or inside the pipe.

Connecting the electric wire to the network should be done when the air temperature in the region approaches 0 degrees. There is no need to wait for frosts: if the water in the system freezes, it will take some time to defrost it. All this time the pressure in the pipeline will be reduced, which is undesirable. A completely frozen water supply without insulation is not only uncomfortable from a domestic point of view, but it can also lead to an emergency. Pipes are deformed under the influence of ice, their walls are torn. This can happen with steel and newfangled plastic products. Heated pipes for outdoor water supply are protected throughout the year.

Any heating cord is an electric wire with a certain indicator of electrical resistance. Products for heating pipes have several or one heating core, covered with a protective insulating layer.

Important! The degree of isolation determines the quality of the self-regulating heating cable for the water supply, because the system will have to work in rather difficult conditions with constant electric voltage from the network.

Choosing a self-regulating heating cable for water supply

On sale there is a mass of finished products for heating pipes with various specifications. The choice of a heating cable for the water supply will depend on indicators related to the system itself:

- diameter of the used water pipe;

- material of which the pipe is made;

- thermal insulation layer thickness;

- approximate calculation of heat loss.

These parameters will affect the power of the heating cable for the water supply and the presence of additional elements in it. When buying a ready-made heating cable for water supply, you must pay attention to the following characteristics:

- Power.

- The presence or absence of a thermostat.

- Rated voltage.

- The length of the self-heating cable for the water supply in the bay.

- The indicator of the maximum working temperature (optimal - 65 degrees).

Installation of a heating cable for water supply: insulation method from the outside

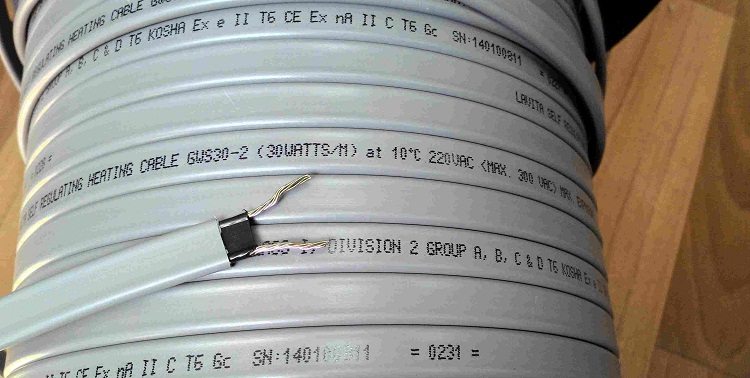

Before starting installation work, it is necessary to carefully check the integrity of the insulation throughout the entire length of the self-heating cable for the water supply. If cracks, creases and other violations of the insulation layer have been detected, the installation of heating is not allowed.

A cable manufactured under industrial conditions does not need to be assembled, it just needs to be fixed on the pipeline

Important! The most serious event in the process of preparing the cord for installation is the switching of the heating part of the electric wire with a “cold” wire.

Sometimes switching is provided by the manufacturer, but if a home-made electric wire is prepared for installation, you will have to do it yourself. Each model of cable for heating water pipes provides a specific type of connection, which is discussed in the instructions that are attached when purchasing. The main objective of this operation is to create an effective electrical contact, which will also be reliably insulated.

Fundamental principles of cable installation for heating water pipes from the outside:

- The standard arrangement of the wire is in one line along the entire length of the pipe. Moreover, certain requirements will be put to the location of the heating element. For example, the wire cannot be on the upper side of the pipe. This is due to the protection of the wire from possible mechanical damage from the fall of various objects from above or forcing the soil. It is also taken into account that liquid freezing usually starts from the bottom of the pipe, which is why this section requires maximum heating.

- The number of wires for pipe insulation can vary depending on individual requirements. If one external electrical wire does not provide sufficient heating power, it is possible to start several heating traces. Their number can reach up to 4.

- There is another method for efficiently heating a pipe system with one wire. The cord may not extend in a straight line, but may be laid on a pipe surface in a spiral. In other words, the heating cable for the water supply simply wraps around the pipeline in compliance with a certain step. This option is economical, but it is not always possible to bring it to life. If there is not enough space in the ditch to let the entire cable inlet pass for heating the pipes, allowance should be left for the loop allowances for subsequent wrapping.

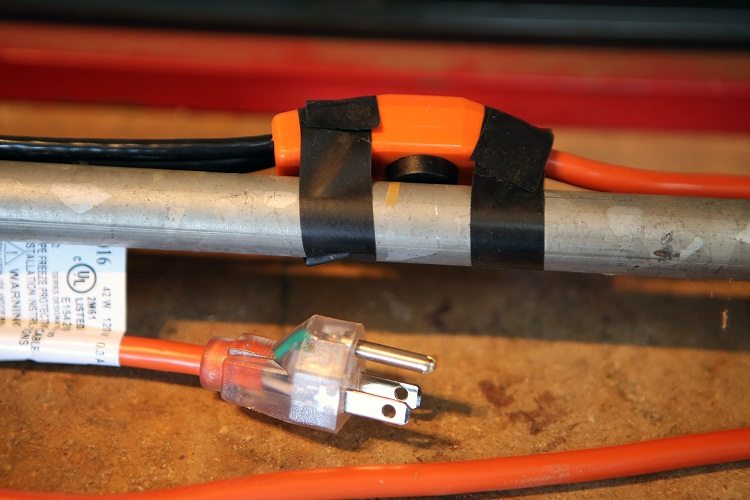

- On the surface of the polymer pipes, the heating wire is fixed with aluminum tape. This material allows you to create a reliable mount, and also contributes to maximum heat transfer from the heating path to the pipeline. The wire must be fixed along its entire length, and aluminum foil can be used on the most problematic ones for better heat transfer.

- If we are talking about installing a warm cable for metal water supply, fixing is done in a ring way using heat-resistant adhesive tape or plastic cable bandage. The step between the attachment points will be no more than 300 mm.

- The installation of a cable for insulation of water pipes at the turns of the system has specific conditions. The wire should be as close as possible to the radius of the outer tap. At the junction of the pipeline with metal fasteners, an additional loop of wire is held near the mount.Cord allowances are also left at the locations of the massive shaped elements of the pipeline: gate valves, flanges or taps.

Helpful advice! A self-regulating cable is associated with consumers with a more economical solution, since the energy costs are in theory controlled. But, as practice shows, a self-regulating heating cable for insulation of a water supply system often works in the same mode regardless of air temperature. Therefore, to be completely sure that there is no unnecessary energy consumption, it is recommended to install a special thermal sensor.

The correct location of the temperature sensor affects the degree of cost control. The temperature sensor cannot be located near the cable for heating water pipes, otherwise its performance will be incorrect. Typically, the sensor is located in the coldest place of the water supply, namely, closer to the top of the pipe.

Installation of heating water pipes with a cable inside

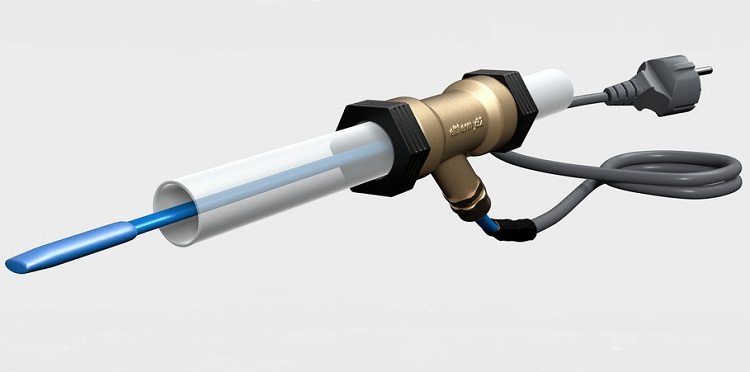

A wire located inside the water supply is more efficient in operation, but its installation is always accompanied by certain difficulties. This method is preferred when the installation of an external cable for heating the water pipe is not possible due to the passage of the system through concrete rings or floors.

The installation of the internal cable for heating the water pipe is carried out using a design designed specifically for the insulation of pipes from the inside. This product has more durable insulation, and threaded bushings and washers with conical or cylindrical seals are included in the kit.

Installation of a heating cable for the water supply inside the pipe is as follows:

- All additional devices are put on the internal cord in the appropriate sequence, and only after that the heating element is switched with the “cold” wire.

- A tee is installed in the area where the wire enters the pipe cavity. A sealing sleeve is screwed into the tee.

- The heating cable for the water supply is located inside the pipe to the required length. The internal electrical wire can heat only straight sections of the pipeline, with the exception of slight bends in the structure, in which the presence of the wire will not impede the passage of fluid. The heating cable for the water supply inside the pipe at the location of the valves, taps or gate valves is prohibited: a threaded connection can damage the integrity of the insulation layer.

- After introducing the cable for heating the water pipe, the stuffing box is twisted and crimped. This is necessary to exclude the possibility of depressurization inside the water supply system.

Before deciding on the wiring of the electric wire inside the water supply system, it is necessary to make sure that the material for the manufacture of the wire complies with sanitary standards for drinking water. Heating the water supply from the inside with a cable is possible only if the diameter of the structure exceeds 20 mm. Otherwise, the pressure inside the system will be below optimal.

The heating cable can also be located inside the pipe, but for such an installation you will need a cord with moisture-proof insulation

Is it possible to make a heating cable for a water pipe with your own hands?

In the event that the cost of a wire for heating water pipes is not acceptable for your budget, you can do the analogue of a purchased cable yourself. For a successful result, you must have at least a superficial experience with electrical equipment.

The most proven way is to create a home-made heating cable for water from a power telephone cable. This wire was used to optimize field communications, it is marked P-274M. This model is used due to the presence of the required degree of insulation and sufficient rigidity.A telephone cord can even be used as an internal heating wire. True, a self-regulating cord cannot be made in this way.

Important! This method of heating water pipes with a do-it-yourself cable assumes optimal sealing of the wire inlet to the pipe. Sealed approach can be arranged using a flange from a flexible pipe for supply. You can also fill the fitting with the wire with epoxy, and then tighten the connection with a nut.

If it is planned to heat the water supply system not inside the pipe, but outside, then the telephone cable is not required to be untied. It should be connected in the opposite side of the site, requiring insulation. Mounting on the inside of the pipeline structure is carried out using aluminum foil and tape. The pipeline is additionally insulated with thermal insulation. In this way, it is possible to create conditions for heating not only the water supply system, but also the sewage system. However, it should be remembered that the current strength cannot reach more than 9A.

The presence of heating cables for water supply is an undeniable advantage, especially for systems running in cold regions. However, such a method of warming is not necessary. If there is an opportunity to do without heating cables for water supply, then it is better to do just that. Digging a trench to a sufficient depth and good thermal insulation should solve the problem of freezing even without complicated manipulations with electric wires.