About 10-15 years ago, the laying of the pipeline was accompanied by blocking traffic, digging deep trenches, which is why residents of megacities faced great inconveniences. But utilities are not eternal, therefore, overhaul of pipelines is required, and often their replacement. And what, again, breaking the asphalt, digging "anti-tank ditches"? No, today there is a worthy alternative. It consists in trenchless laying of pipelines.

Trenchless pipe laying is a modern method that allows you to quickly create a water, gas or heating main without digging trenches

Content

Modern methods

This technology allows you to save a lot of time when replacing engineering communications with a new one, to avoid inconvenience and to solve the problem of carrying out a pipeline under roads and highways with busy traffic. Now workers can quite quickly lay pipes over considerable distances and to great depths without digging trenches.

Currently, installation and repair of pipelines is carried out using the following types of trenchless technology:

- Horizontal drilling. Drilling is being performed using a drilling rig. Moreover, the hole itself can have a diameter much larger than the cross section of the pipe being laid. Such a technical solution allows workers to adjust the drill route in order to work around an obstacle.

- Piercing. The soil is pierced using a special pipe equipped with a tip made in the form of a drill. Piercing is carried out a short distance. This method is used for small diameter pipelines.

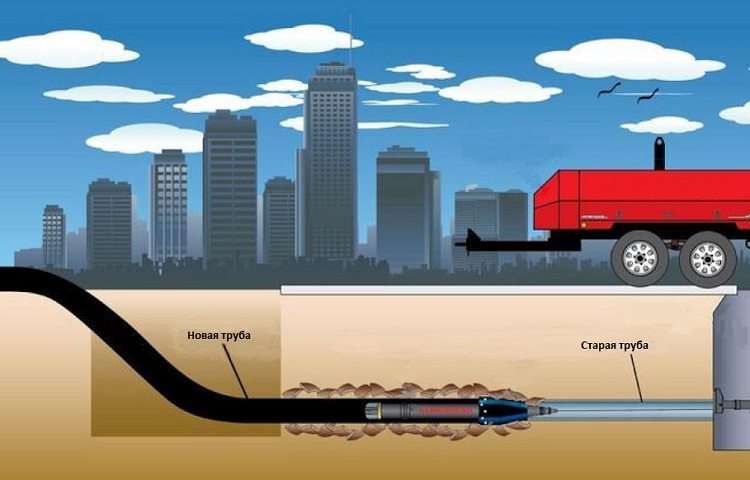

- Punching. For lines of much larger cross section, punching is used. This technology allows you to lay pipes without trenches already at a considerable distance. It has found the greatest application in replacing steel pipelines, and the methodology for the behavior of the work is fully consistent with its name.

- Remediation is precisely the trenchless replacement of sewer pipes.

Laying engineering communications without a trench provides for the following factors:

- distance of the proposed pipeline;

- the material of manufacture of the pipe itself and its diameter;

- the nature of the soil at the place of passage of a sewer or other highway.

These factors affect the choice of one of the above methods of laying a sewage system. And the type of suitable drill is determined based on an analysis of the nature of the soil.

The advantages of modern technology

Even a person whose occupation is not connected with laying pipelines can easily understand all the advantages of trenchless technology.

- communications passing near the pipeline are not at risk of loss of operability, while bursts of neighboring networks were repeatedly recorded during digging of trenches.

- there is no need for subsequent repair of asphalt or paving of paving slabs.

- preservation of the landscape, green areas.

- It is possible to lay and carry out repair work in the winter.

- speed of work.

- minimal damage to the environment.

- emergency situations practically do not occur.

Important! Such a technology is very cost effective. After all, it is not necessary to connect labor and additional equipment for earthwork, as well as for backfilling the trench.

The trenchless method is safe, it allows you to save buildings, plantings, asphalt pavement of roads and sidewalks near the work

In addition, trenchless repair of sewer pipelines has another important advantage, consisting in the absence of the need for special excavation preparatory work. For example, laying pipes from polyethylene in a trench is usually carried out using an excavator, followed by arranging at the bottom of a shock-absorbing cushion, which is a mixture of sand and gravel. At the final stage, backfilling of the trench of the trunk line is performed, while the soil is compacted and rammed. A closed way of laying communication requires only a well-designed project of work, a thought out optimal route without turns and bends, compliance pipeline slope and the depth of its occurrence.

Technologies for trenchless replacement of sewer pipelines

The best solution to avoid repairing the sewage system is its prevention. But if, after all, a nuisance happened, and the pipeline began to leak, a professionally performed rehabilitation will help out.

Relining. A brief description of this procedure is formulated as follows: the internal cavity of the damaged section of the sewage pipeline is filled with a flexible polymer sleeve by pulling it. In this case, the old pipe may collapse. To prevent this phenomenon, before you begin to stretch a new pipe, you need to study the condition of the cavity of the old one, since there may be foreign objects and other insurmountable obstacles.

If it is necessary to preserve or increase the diameter of the pipeline, the method of static cracking is used. This procedure is performed in the following sequence:

- a digging pit 2 × 3 meters in size is digging;

- from its side rods are passed through a destructible pipeline;

- in a previously dug starting pit, an expansion knife is attached to the end of the rods. It is connected to a stretched HDPE type pipe through a swivel;

- hydraulic jacks are mounted on the frame located in the receiving pit. The rods are pulled in them;

- the carriage on which the rods are mounted is driven by jacks. To better fix the frame, a persistent plate is pre-installed in the pit;

- the polymer pipe extends until the expansion knife fully exits into the receiving pit;

- while pulling the bar (their length is 1.5 meters) periodically removed.

During the above procedure, the old pipe is cut with a knife, expanded, and a new plastic pipe is drawn into its cavity.

There are nuances of relining. Home masters, choosing a method of repairing a pipeline, as a rule, give preference to this particular method because of its economy. At the preparatory stage, the diameter of the stretched HDPE pipe is selected so that it ideally fits the size of the cross section of the restored branch of engineering communications. Pipes with a length of about 10-12 meters are pre-welded, after which they are introduced into the area of the system for removal of human vital products that is to be repaired.

Important! The maximum length of the welded pipeline is 700 meters.

Relining performance is the derivative of the diameter of the pipes.Repair of pipelines using this method allows replacing up to 250 meters of the sewer system within 24 hours.

It must be remembered that butt welding is accompanied by the formation of a collar with a height of up to 1.5 cm at the junction of the pipes. When measuring the gap between the new HDPE pipe and the inner surface of the pipeline being restored, this nuance must be taken into account. Here, one should take into account such a factor: with a decrease in the diameter of the repaired pipe, the throughput of the line, if it becomes less, is very insignificant. This is due to the low hydraulic resistance of the inserted HDPE pipe.

And one moment. Reorganization by relining is permitted only in cases where a change in the diameter of the pipe is permissible within small limits, or if it is compensated by an increase in the throughput of the new line.

Trenchless replacement of pipelines, in which the old element of engineering communication is destroyed, after which the new pipe is pulled, will be useful when relining does not produce the necessary pressure during restoration of the network line. Construction organizations prefer this method if:

- work is carried out in difficult hydrogeological conditions;

- other communications or buildings are located near the pipeline being repaired.

Highway renovation. This method of rehabilitation involves the complete destruction of the old pipe while laying a new one in its place. It is used in the following two cases:

- insufficient bandwidth of the existing branch of engineering communications;

- the pipe has expired.

In this case, the diameter of the laid line can change in the direction of its increase or decrease.

Remediation of this type is usually carried out in two ways:

- using a pipe breaker;

- replacement of the operated area with a plastic branch, consisting of HDPE pipes connected by a thread.

During renovation, the destruction of the old pipeline is carried out by cracking by the static method. The area where the problem was detected is first cut with roller knives. Then a special expander increases the diameter of the tunnel. The final stage of the pipeline replacement is pulling a new segment.

Trenchless sanitation technology Primus Line

This method is used to restore the operability of water, gas and oil pipelines. It is based on the use of a flexible high-pressure sleeve and a connection technology specially developed for this system. The multilayer structure of the sleeve and the insignificant wall thickness give the structure flexibility and high strength. The inner layer is selected depending on the transported working medium, while the outer layer is in any case made from an abrasion-resistant variety of polyethylene. The role of a statically supporting layer is played by the seamless aramid fabric present between these layers.

The sleeve is drawn into a worn pipeline through small pits. This technical solution does not require opening the roadway. The Primus Line element with an old pipe product does not stick together and is self-supporting in the annular space. To existing pipes (made of PE, steel, cast iron, etc.) and, thus, to the network, the sleeve is joined by means of special high-pressure connectors. Especially for water pipelines supplying drinking water at low pressure, the Primus Line system was designed, the nominal diameter of which varies in the range of mm.

Important! The connecting technology of the new system has been modified so that the final product is able to withstand the required working pressure.

The connector design includes a molded inner sleeve and an outer sleeve. On the inside of the latter there is a deformable steel shell. Creating a long tight connection occurs by pressing the resin with a pump through the valve of the outer sleeve. As a result, the steel shell, and with it the Primus Line, is pushed into the contours of the above inner sleeve. When the resin hardens, you get a reliable and durable, leak-proof compound.

U-Liner Trenchless Remediation

This technology was developed by specialists of the world famous German company REHAU. Its essence is as follows: a plastic pipe rolled in a special way is inserted into a problem cast-iron pipe, then it is pulled. The next stage is the preparation of this polymer product for the process of transforming a section from a U-shape, which was obtained during its folding into a round one.

To this end, the pipe is closed on both sides, and hot steam is generated in its cavity, generated by a special unit.

On a note! It could be assumed that steam is supplied under high pressure, the level of which is able to change the configuration of the rolled pipe. But this is not so. It is high temperature that activates the specific properties of the material, due to which the plastic takes its original shape - in this case round.

The following point should be noted. Despite the fact that such trenchless repair of sewer pipelines is designed primarily for municipal utilities and water utilities, it can also be used with a high degree of efficiency in the private sector.

The development of REHAU significantly outperforms the traditional trench method. This statement is supported by the following figures: sanitation of pipelines by this method is carried out 10-14 times faster, and savings, taking into account the specific conditions of the facility, are 10-30 percent.

In addition, the installation and repair of pipelines using U-Liner technology practically does not cause a decrease in the throughput of the pipeline. This is due to the fact that the roughness coefficient of the inner surface of the polymer pipes is approximately 0.01 mm. Thus, deposits are not formed in the engineering communication cavity, and the friction of the working medium against the walls is minimal. The process of restoration of the pipeline does not depend on the degree of its wear - it can even be in emergency condition. The reason lies in the fact that the element of the U-shaped configuration, having taken a rounded shape, becomes a self-supporting pipe that accepts all work loads.

A few words about the types of sleeves. The following models were most widely used:

- TUBETEX (Tubtex). For the manufacture of such a sleeve, polyester high-strength yarns with circular weaving are used. At one of the stages of production, a layer of polyethylene coating is applied to them. Minimal stretching - this is the main advantage of a sleeve with circular weaving. This property allows you to block inside the pipe all the irregularities formed during its operation.

- COMBILINER (Combiner). The use of this type of sleeve is an excellent solution, the code requires trenchless replacement of heavily worn large-diameter pipes. The combiner combines the attractive properties of a felt and woven sleeve. It resists external and internal pressure. And due to the fact that it becomes a self-supporting structure, the outer pipeline experiences less deforming effects.

And in conclusion, one of the recommendations of experts. In a megalopolis, trenchless pipeline restoration technologies should be preferred when the networks to be repaired are laid below other underground structures.