Recently, the following trend has become clearly visible: the number of our compatriots who prefer internal pipe wiring made of copper is increasing rapidly. This is due to the presence in copper pipes of such characteristics as durability, the ability to withstand high pressure. And, of course, high strength. Their installation carried out by special fittings for connecting copper pipes.

Content

Application and types of fittings

Almost all of the copper piping elements produced by modern industry comply with the requirements of European ISO 9002, British BS2 and German DIN standards. In addition to the above characteristics, all of them have high bactericidal properties. That is, the probability of water contamination by pathogenic bacteria in engineering systems made of this metal is minimal. Copper pipes and fittings for copper pipes are used in the installation of all types of plumbing communications:

- water supply systems;

- gas supply;

- heating;

- air conditioning hydraulic and pneumatic systems.

Copper pipes can be easily cut and bent, and fittings are simple and reliable. The service life of a water supply system made of this metal is about 80 (!) Years. The connection of parts in each of the above systems is carried out using different types of fittings. If you use the method of connecting to pipes as a criterion, then these elements are divided into:

- threaded;

- capillary;

- compression. Their other name is crimp fittings;

- press fittings;

- self-locking fittings;

- fittings for welding.

All types of fittings are equipped with a calibrated bell at the production stage. This allows installation to be carried out as soon as possible, without prejudice to its quality.

The designs of products of the same type may differ depending on the scope: gas supply, drinking water supply, non-potable water supply, heating. Consider the main features of the most common types of copper pipe fittings.

Helpful information! The standards in force in our country govern the following fitting parameters: wall thickness, outer and inner diameters, gap width of the fitting pipe, socket depth, smooth end length.

Threaded fittings

Such products are used when it is necessary to frequently assemble / disassemble engineering systems, create branches, turns and for connecting, mainly, thick-walled pipes of one, as well as various diameters. According to the name, all fittings of this type are equipped with a cylindrical thread. Moreover, both internal and external. Installation of threaded fittings for copper pipes is necessary in an accessible place, since they are subject to constant inspection. Depending on the design, such elements are divided into the following groups:

- bends;

- crosses;

- couplings;

- stubs;

- nipples

- squares;

- tees and others.

Threaded fittings are equipped with a special crimp ring. By tightly attaching it to the pipe, a high tightness of the connection is ensured.Threaded fittings are available with or without a protection layer. The most commonly used coatings are zinc, chromium and nickel. Such a layer enhances the properties of copper and increases the strength of the connection. To ensure its tightness, special materials are wound on the threaded part of the fitting: FUM tape, tow with paint, etc.

Crimp (compression) fittings

Installation of pipes using parts of this type is convenient in that it does not require special equipment and high temperature. That is, with crimp fittings for copper pipes, you can work in hard to reach places. To do this, you will need tools such as a cutter, calibrator and wrenches.

Other advantages of these products include a reduction in labor costs, a reduction in the time required to complete the work, and the result is a durable and airtight system. However, compression fittings must not be placed under concrete, as they must be checked and tightened periodically.

The design is reusable. In other words, after dismantling the segment of the pipeline fastened with such parts, they can be used in the future.

Helpful information! Installation of fittings for copper pipes for crimping is recommended for connecting engineering communications elements made of different materials.

Device and features. The compression fitting includes the following parts:

- Body.

- Crimp ring.

- Crimp nut.

Tightness, durability and the ability to withstand high pressure provide the connection precisely crimp rings (usually they use one or two).

In addition, thanks to them, the design becomes resistant to vibrational fatigue and can serve for many years.

The raw materials used in the production of compression fittings for copper pipes are brass, copper, steel and plastic. Brass fittings are more popular. This is due to the fact that this material is cheaper than pure copper, and is easy to process. And in terms of "strength" it is comparable to stainless steel. Often, brass compression fittings are additionally treated with nickel at the production stage. This provides resistance to various negative influences.

When choosing a product, pay attention to its weight. For brass crimp fittings for copper pipes, it should be relatively big. Do not be shy and ask the seller to show a certificate of quality. This will protect you from wasting money, and the installed system will be reliable. Professionals recommend purchasing parts that came off the assembly line of a well-known manufacturer.

Brass fittings can also be used for HDPE pipes. They provide a margin of safety greater than plastic and are not susceptible to corrosion.

Installation

When realizing the connection of copper pipes with crimped fittings with your own hands, you need to know that there are some nuances here. So, when buying, pay attention to the labeling of these products. According to the European classification, it must include one of the English letters A or B. Installation of above-ground pipelines, for the manufacture of elements of which semi-solid grades of copper were used, is performed by compression fittings exclusively of type A. Type B is designed for thick-walled pipes made of semi-solid and soft grades copper. It is applied to elevated and underground pipelines.

Installation of compression fittings of both types is carried out according to the following scheme:

- selection of the connection element of the desired size.It is not difficult to do this, since manufacturing enterprises are guided by the requirements of a single European standard in strict accordance with the nomenclature;

- Obtaining a pipe segment is necessary in size by cutting it crosswise. Deburring. Calibration of the cut caliber. Cleaning the surface of the pipe from dirt;

- put the crimp ring on the pipe. To prevent the seal from tearing or slipping, the joint can be moistened with water;

- Having done this, push the pipe all the way into the fitting. First tighten the clamping nut by hand, and then tighten using a wrench.

To get the most reliable connection, you must strictly adhere to these rules.

Helpful advice! Excessive effort will be unnecessary here. From this, the tightness of the connection will not increase.

When using low-quality compression fittings for copper pipes, you risk squeezing the ring, which will lead to the need to replace the entire part.

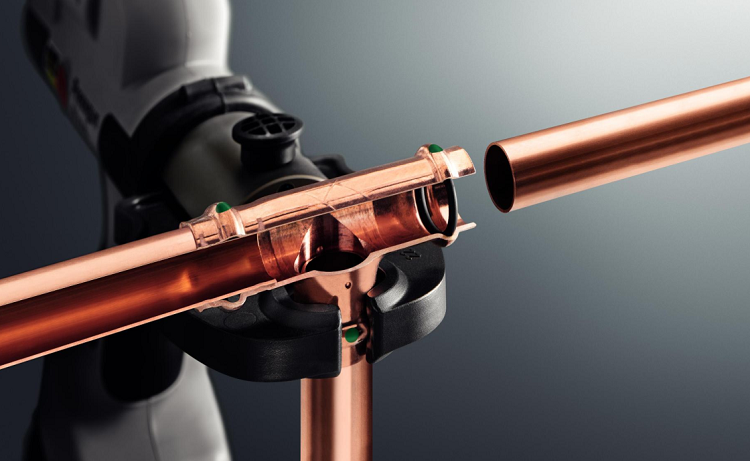

Press fittings

The possibility of realizing such a compound is based on the ductility of copper, which ensures its susceptibility to deformations created by mechanical stress. Installation is carried out as follows: first, the pipe is inserted into the press fitting, after which it is crimped with special pliers along the contour of the connection element. As a result, a characteristic impression remains on the surface.

A permanent, solid mechanical connection is obtained when crimping is performed with a force exceeding 32 kN. The joint sealing is provided by the sealing element inside the fitting: the action of the external compressed sleeve determines its tight fit to the outer surface of the pipe. One of the features of this technology is that the press fittings for copper pipes can be rotated along their longitudinal axis. But this does not affect the tightness of the joint and its quality in any way.

Capillary fittings

So-called copper fittings for soldering. The connection of the pipes in this case is carried out using solder. The technology is as follows: a small piece of wire (made of tin, copper or silver) is placed inside the tube on its base. Then the fitting is put on. After that, it must be pressed firmly to the pipe. In any case, some kind of clearance remains. Then, using the burner, the pipe heats up.

High temperature causes the wire to melt, as a result of which the liquid metal, filling the gap, fastens the two parts together. When the working section of the pipe has completely cooled, it must be cleaned and checked for leaks.

This method is characterized by the following advantages:

- long service life of the final product;

- the seam is able to withstand high pressure in engineering communications;

- high resistance to temperature fluctuations without compromising the quality of the seam;

- the seam has an aesthetic appearance;

- minimum level of material consumption for solder;

- the ability to perform this procedure with your own hands, as well as the low cost of installation work.

But it was not without some drawbacks. Firstly, the implementation of the method of connecting pipe segments using capillary fittings requires burners. And secondly, the performer must have working skills, even minimal ones, with similar materials.

Important! For each specific case, you need to choose your type of fitting. Only then will the pipeline be durable and of high quality.

With copper fittings, you don’t have to adapt to the material, and you can assemble the system so that it is both sealed and practical. And installation will take much less time than if you did it using other features.