Outer and inner diameters are the main parameters of the pipes. The length of the pipeline, its working pressure, the parameters of the transported medium and the general functionality depend on these indicators. Since iron and non-ferrous metal products are standardized products by GOST, the diameters of copper pipes are expressed in inches and millimeters. It is important to be able to translate these values in order to exclude an error in matching. Especially when it comes to the articulation of sections of the trunk from another material, since each type of pipe is produced according to its own standards.

Copper pipes are available in different sizes, the diameter of the products is indicated in inches or millimeters

Content

What is important to know about pipe parameters?

Length and diameter are simple parameters, expressed in digital terms, so that it is easier to measure and enter a value in the formulas. But in reality there are several parameters for measuring the thickness of the pipes, and accuracy is needed everywhere.

It is interesting! The discrepancies in measurements arose due to the introduction of copper pipes in the construction technology of Europe since the mid-twentieth century. Then, in our territory, the main standard was defined in millimeters - for iron products, which are widely used even today. Domestic apartment buildings are equipped mainly with steel water supply.

In Europe, private households with copper communications are more popular. They are the most durable, resistant to corrosion, but with high cost.. Seamless copper products are gradually gaining their market segment, they are also produced according to GOST. They are used not only for plumbing communications, but also to ensure work:

- split systems;

- solar panels;

- refrigeration units;

- autonomous heating;

- parts for mechanical engineering.

For different segments of the pipeline, pipes of different sections are used, and it is important to know which diameter is suitable for a particular purpose

Basic values for measuring pipes

Specialists distinguish the diameter of copper pipes:

- nominal;

- interior;

- outer.

There are also such general concepts as "conditional pass" and "wall thickness". Without specifying dimensions, they say that the product is "thick-walled" or "thin-walled." All diameters of copper pipes should be indicated in their marking - in inches and millimeters.

- The wall thickness of the product, the value is indicated in "mm", the parameters are related to the volume of the passing substance and its pressure. A significant indicator remains the difference between the inner and outer diameters.

- For a good connection of the trunk through the fittings, a conditional passage is important - the internal clearance of the product, millimeters are also used for its designation. On imported non-ferrous metal products, it is indicated in inches, which requires translation into “our” values.

- The inner diameter is the main indicator of the throughput of the pipeline (mm), used for calculations in formulas.

- Outer diameter - important for the classification of products (large, medium and small), indicated in "mm" in all tables.

- The nominal diameter is roughly the same as the “conditional pass", but marked with the exact value.

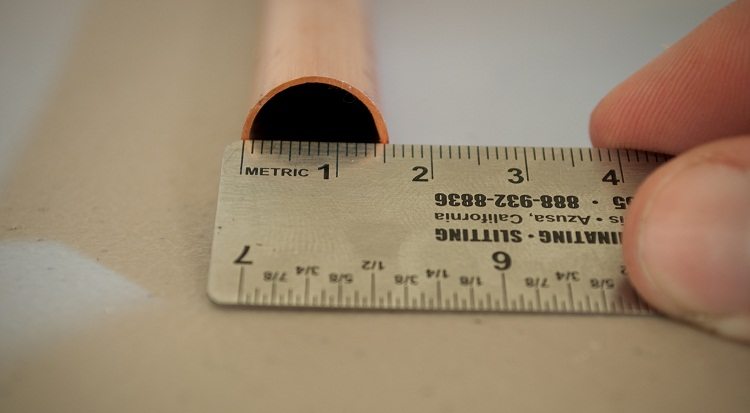

Attention! Roulette or centimeter tape gives approximate values; calipers and measuring equipment give exact values.

Today, the materials from which pipes for highways and domestic water pipes are produced are limited to a small list:

- steel;

- plastic, metal plastic;

- aluminum, copper, other light alloys.

Some copper pipe sizes are indicated in inches, for example, inch or half inch. This means that the inner diameter is expressed as 1 inch or ½ inch - about 25.4 mm and 12.7 mm. Specialists in laying highways pay attention to these values in order to choose the sizes for the copper pipe:

- couplings;

- tees;

- threaded fittings.

How to convert inches to millimeters

Metric parameters are often used for external measurements of the diameters of copper pipes, and inches for internal ones. Use tables to convert inch values to millimeters.

Table 1

| Pipe size inches | Outer diameter mm | Equivalent Diameter, mm |

| 1/4 | 13,5 | 8 |

| 3/8 | 17 | 10 |

| 1/2 | 21,3 | 15 |

| 3/4 | 26,8 | 20 |

| 1 | 33,5 | 25 |

| 1+1/4 | 42,3 | 32 |

| 1+1/2 | 48 | 40 |

| 2 | 60 | 50 |

| 2+1/2 | 75,5 | 70 |

| 3 | 85,5 | 80 |

| 3+1/2 | 101,3 | 90 |

| 4 | 114 | 100 |

| 5 | 140 | 125 |

The size in "mm" is converted to "inches" with rounding up. 1 inch is 25.4 mm, but with rough rounding, an error is obtained, which is important to consider when choosing a range.

table 2

| Inches | Millimeters |

| 1/2 | 20 |

| 1 | 25 |

| 1/1/4 | 32 |

| 1/1/2 | 40 |

| 2 | 50 |

| 2/1/2 | 65 |

| 3 | 89 |

| 4 | 100 |

Converting inch to metric sizes is a simple procedure, but it requires attention. The mismatch of the parameters of the details of the future pipeline will deprive the master of the opportunity to install, or the connection points will be leaky, which will make it impossible to use the trunk.