Arrangement of pipelines for various purposes in a residential building is the most important stage in the repair process. A single and equally successful solution in all cases will be the installation of a pipeline of copper pipes. Copper meets the requirements for both water supply systems, and heating or gas supply. This material is universal in its properties, as well as in its special production technology. This metal has no drawbacks, so the copper pipeline is a rational approach, a guarantee of comfort and safety.

Content

Characteristics and indicators of copper pipes

The popularity of copper can be explained by referring to its following advantages:

1. Absolute inertia. Copper is a chemically neutral element. In domestic conditions, copper does not enter into any reactions even with aggressive environments. Copper is impervious to liquids and substances of any type: metal does not change its structure during prolonged interaction with a heat carrier, liquefied gas, fats, oils.

Copper pipes and fittings for water supply are special in that they are not destroyed by the action of chlorine, which is almost always present in hard tap water. Moreover, chlorine promotes the development of natural protective qualities in copper - an oxidative layer forms on the walls of products made from this metal, which provides additional structural strength.

2. Security. Copper structures successfully operate both at extremely low temperatures (-200 degrees), and at high (more than +250 degrees). Moreover, the system is not threatened with sagging or rupture due to sharp temperature fluctuations: the coefficient of linear expansion of copper is very low. The material itself is extremely plastic, the copper pipe is able to withstand even repeated freezing of water in the system.

The walls of copper pipes, as in the case of plastic pipelines, remain smooth throughout their life. The owner of the copper pipeline will not have problems with clogging of the system due to organic or inorganic deposits on the walls of the products.

3. Simplicity mounting. The manufacture of pipes and fittings is carried out using phosphorus deoxoxidized copper (grade CU-DPH), represented by an alloy Cu + Ag (99.9%) and an admixture of phosphorus (not more than 0.040%). Products from this alloy lend themselves perfectly to soldering, without losing their positive properties even after several decades of operation. Information on the alloy used in the production should contain a certificate from the manufacturer.

4. Aesthetic qualities. If for some reason the owner is not satisfied with the natural reddish color, the pipeline can be painted with any paint suitable specifically for this metal. There are no protective functions for copper paint, since the pipeline itself does not need additional protection. A chrome-plated copper pipe with a spectacular metallic color can also be used for external broaching.

The weight of the copper pipe differs significantly from similar structures made of steel or, especially, cast iron. The weight of a meter section of a pipe with a diameter of 12 mm and a wall thickness of 1 mm will be about 300 grams.

The aesthetic qualities of copper pipes allow the use of ordinary water pipes from them as an interior detail in a certain style

Good to know! From products made from other metals, these products also have a very high melting point. For example, all pipes that have a certificate in accordance with GOST 617-2006, melt at a temperature of +1083 degrees.

Before they go on sale, copper pipes pass a test that includes not only an assessment of the technical characteristics, but also the appearance of the product.

Varieties of copper piping

Copper pipes for water and gas are produced in accordance with the standards described in GOST 52318-2005. All companies offering their products for mass sale must have a certificate of compliance with this document.

All copper pipesused in the household can be divided into two categories:

- annealed;

- unannealed.

Annealing is a special heat treatment during which products become soft and plastic. The annealed copper pipe slightly loses its strength properties, but its installation at the same time requires less time and physical effort.

Annealed copper pipe It is supplied in bays, the length of which is usually from 2 m to 50 m. The area where soft copper is used is very wide: these are gas supply systems, freon, air conditioning and condensate drainage systems. Unannealed copper products are sold in segments of 5 m, and are mainly used in the field of domestic water supply and heating.

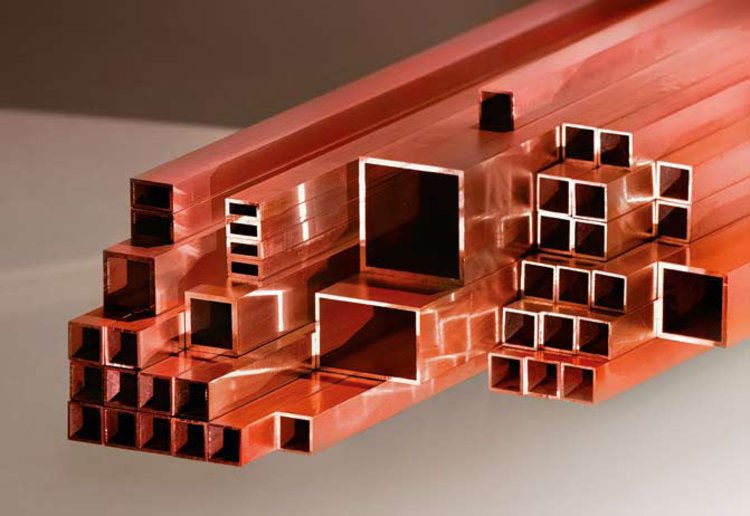

Copper profiled pipes can only be used as cable channels for laying electrical networks and as elements of furniture or room decor

Another variety of unannealed products is a copper pipe of rectangular cross section (profile). Unlike steel profile steel, such pipes are inappropriate to use as supports for structures. Copper profiles are necessary for the manufacture of stator conductors for electrically driven machines, which are cooled by a liquid method.

Important! Copper profile structures can be called rare and rather expensive products, since their production is fraught with a number of difficulties (profiles remain seamless).

The manufacturing technology of copper profiles is regulated by GOST under the number 16774-78, and the certificate presented by the manufacturer will speak about compliance with the standards.

Why do we need a copper pipe in isolation?

Despite all the advantages, a copper pipe pipeline still involves some additional costs for even better work.

An insulated copper conduit loses one of the main drawbacks of the metal - its excessively high thermal conductivity. The need for insulation is especially acute if it is planned to heat or hot water from metal pipes. The coolant in a non-insulated system can cool too quickly, while the walls of the pipeline heat up too much and quickly, which is also not quite convenient.

Pipes in polymer insulation can reduce heat loss in the heating system, but such products are quite expensive

Insulation on copper construction is absolutely necessary if hidden wiring is needed: the pipeline will be laid in the wall gates, and masked with plaster from above. Insulation made of foamed polyethylene (rubber or thermaflex) will solve several problems at once:

- wet plaster in the passage of the heating main due to the formation of condensate;

- protection against constant exposure to the surface of the pipe with plaster;

- prevention of destruction of the plaster layer due to slight expansion of the pipe when heated.

Metal pipes can be produced with factory insulation, but the cost of such sets will significantly exceed the price of conventional products. A more economical solution would be to purchase separate insulation of the required diameter and thickness.

Insulated copper pipe is also suitable for underfloor heating. In this case, the polymer layer will protect the system from constant mechanical stress and pressure.

Using a copper pipe to conduct gas

The gas pipeline can be built both from a soft copper pipe, and from unannealed and reinforced copper. According to the manufacturing method, a gas pipe is both seamless (seamless) and welded. The latter option will be cheaper, but less reliable. Of course, the concept of less reliability in the case of copper structures is quite relative.

Important! Gas pipes do not fit into walls, but may require the use of insulation to reduce heat loss and protect against any impact.

Before putting the gas pipeline into operation, copper pipes must pass the test of a special commission to obtain permission to turn on the gas supply.

The peculiarity of gas unannealed pipes is such that after prolonged storage in storage conditions, their walls become somewhat more fragile. Additional annealing can solve the problem. But this rule proves that large batches of this type of product cannot be purchased: in case of natural aging, even the certificate provided cannot guarantee the maximum quality of the product.

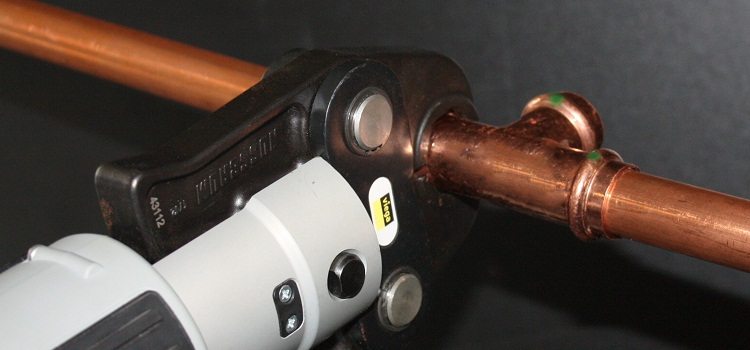

The gas connection fittings are usually subject to the same certificate of conformity as the copper pipe. Compression fittings must be marked yellow: usually, the o-ring of the fitting is painted yellow. For high temperature brazing, special shortened fittings are used. Quality test soldering copper pipes produces a pressure test (pressure test).

If it is necessary to connect a copper gas pipeline to a pipeline having galvanized steel parts, rubber gaskets that act as dielectrics must be used. Otherwise, the electrochemical processes that occur when several metals come into contact will cause premature corrosion. Copper pipes can be combined with brass fittings.

Knowing some of the nuances in the properties of copper pipes for water supply, heating, a gas pipeline and fittings for them will help get rid of possible problems that may arise even in the operation of a pipeline made of an expensive and noble metal.