Seamless pipes are a type of metal rolling, the production technology of which provides for the absence of any seams along the entire length of the products. Such parts do not contain other compounds. Such continuous blanks are made on special rolling machines. Therefore, the production process is called "rolling."

Content

Features of seamless products

Seamless pipes are solid products and do not contain seams, as well as other compounds. First of all, depending on the production technology, seamless pipes are divided into two types:

- hot rolled;

- cold rolled.

There are also seamless parts that belong to a special group of seamless metal products. Such products are characterized in that they have thick walls.

Products that have a seam, in turn, are performed using two main methods:

- welding (the workpiece is welded in a spiral);

- folding (a folded sheet is fixed longitudinally with a special fold).

Helpful information! Seamless pipes are characterized by high strength characteristics, so they are usually used in communications with high pressure ratios.

The material for such parts in most cases is steel. This is due to the fact that this material has high strength. Consider other advantages of these products:

- high coefficient of thermal conductivity;

- low rate of linear expansion;

- corrosion resistance of thick-walled products.

The main disadvantages of such products include:

- high price;

- complicated installation.

In order to lay communication from such pipes, the correct calculation of the main parameters is important. These include indicators of the cross section of the pipes and the thickness of their walls.

Operational field

Seamless pipes are used in critical structures that operate under high pressure. For transportation of toxic substances, mainly hot-rolled seamless products are used.

In addition, products made by hot rolling are widely used in the automotive industry, aviation, etc. They are also used to transport aggressive chemicals and oil (chemical and oil industries).

The use of such parts is also in demand in the utility sector. Of these, various economic communications are mounted that transport hot water, cold water, gas, as well as sewage (sewer system).

In the coal mining sector, such products are used to divert steam and other products from equipment. In addition, continuous pipes are used in the defense industry, shipbuilding, and metallurgy. Extensive operation of seamless products due to their high reliability. Of these, quite complex, from a structural point of view, communications are carried out, which are used in heavy areas of production.

Hot Rolling Seamless Pipe Technology

How to make a seamless tube using the hot rolling method? This process is accompanied by large financial costs, so the cost of such products is also quite large. Let us consider the phased production of seamless pipes by means of the most popular method - hot rolling:

- At the first stage, preparatory work takes place. The workpiece is prepared for further processing. The workpiece is a hollow element that has certain indicators of section and length. The manufacture of such a workpiece occurs from a special type of steel. Before rolling this primary element, it is heated to high temperatures (1180–1200 ° C).

- At the second stage, the formation of the sleeve. The sleeve is obtained using a special high-power drill, which drills a hole of a certain size in the workpiece. After completion of the process, the part already resembles a pipe, however, is not the final product.

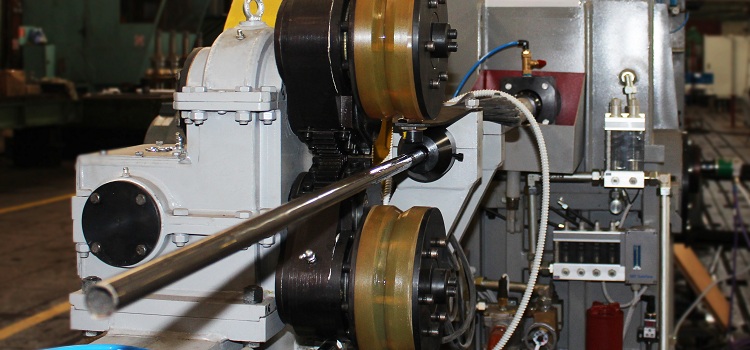

- And finally, in the third stage, the main process occurs - rolling. Rolling involves a number of processes: the sleeve is placed on special rolling machines, which include several rollers, then the sleeve located between the two rollers is gradually stretched in one of the directions. An element for controlling the diameter of the future pipe is a special restrictive element.

Note! In order for the finished pipe to meet the necessary parameters, the above manipulations are carried out several times, until the desired product is obtained.

It is also worth noting that the production of seamless pipes is a complex process that requires compliance with all technical standards and safety rules. The production of seamless metal rolling is carried out only at special enterprises equipped with all the necessary equipment for this.

Hot rolled pipes are produced using a fairly sophisticated technology that requires special control.

Cold pipe seamless pipe production technology

Cold-rolled products are characterized by high strength characteristics, and also have a perfectly smooth surface, which is a very important factor for various communications.

How to make pipes using cold rolling? Let's consider this process in stages:

- First of all, the procurement undergoes a set of cleaning measures. These measures include:

- cleaning with chemicals;

- etching.

In addition, it is worth noting that often the workpiece is processed with phosphates or copper, which increases its strength characteristics. Subsequently, such products have good resistance to deformation.

- Then, with the help of the rollers, a round section is formed. It is worth noting that the angle of rotation of the rollers can vary, which, in turn, entails a change in the caliber of the pipe.

- When performing a round gauge of a pipe with a large diameter, an additional procedure is performed - compression.

If it is necessary to reduce the cross section of the product, the process is repeated, after which the necessary condition is to carry out additional procedures - pickling and washing.

Varieties of seamless tubular products

Seamless or molded products are primarily classified by length and are:

- measured;

- multiple to measured length;

- unmeasured.

According to GOST, there is a clear division of seamless pipes by size. For example, the cross-sectional indicators of hot-rolled seamless products range from 25 to 700 mm, and their wall thickness can be from 2.5 to 75 mm. The length of non-dimensional parts ranges from 4 to 12 m. Cold-drawn products have a cross-sectional index of 8 to 450 mm and a wall thickness of 20 mm. The length of cold drawn seamless parts ranges from 4.5 to 9 m.

Note! Seamless pipes are divided into 4 main categories, each of which, in turn, has 4 subgroups.

Seamless parts are considered the most reliable, as they have the highest strength characteristics and are produced from cast billets. In the process of manufacturing a seamless pipe in a monolithic billet, a hole is made that has the necessary sectional characteristics. It is also worth noting that in the case of seamless steel products, their wall thickness is 6–13 mm.

In addition, all seamless products are classified according to the steel grade. Today, there are about 10 grades of steel, of which it is allowed to produce seamless metal rolling.