Despite the appearance on the market of a huge number of pipes made of polymer materials, steel structures do not give up their positions. They are still widely used in many industries, construction and households. Steel pipes, especially galvanized, are very durable, durable and easy to install. Sorts of steel pipes are determined by GOSTs, regulated in 2003 and 2006, as well as some regulatory documents preserved from the second half of the last century.

Content

The main GOSTs on steel pipes

Technical characteristics of each type of steel pipe, depending on the method of its manufacture, are determined by the relevant GOST. It is necessary to get acquainted with the contents of regulatory documents at least in order to know the features of the operation of a certain type of pipe.

GOST 30732-2006. Regulatory document number 30732 was adopted in 2006, and its effect extends to pipes and steel fittings with thermal insulation. Steel pipes made using polyurethane foam insulation (PUF) with a polyethylene sheath or a protective coating of steel are used for laying heating networks under and above the ground. They are designed for a coolant temperature not exceeding 140 degrees (with a short-term increase to 150 degrees). The maximum allowable working pressure for steel pipes with insulation according to state standard 30732-2006 with the presence of foam insulation is 1.6 MPa.

GOST 2591-2006 (88). GOST, which defines the assortment of hot-rolled steel, has been in force since 2006. Some sources use the old GOST - 2591-81. The provisions of the document apply to square steel products obtained by the "hot" method. In GOST 2591-2006 (88) all products are included, the sizes of the sides of which are in the range from 6 to 200 mm. The production of larger square pipes is possible only with the agreement of the manufacturer’s contract with the buyer.

GOST 9567-75. A version of the document adopted in 1975 is currently in use. This standard specifies the provisions observed in the manufacture of precision steel tubes. These products are characterized by increased manufacturing accuracy: they can be either cold-deformed or hot-rolled (they can also be galvanized or chrome-plated). Pipes of increased accuracy according to GOST 9567-75 are mainly used in the engineering industry.

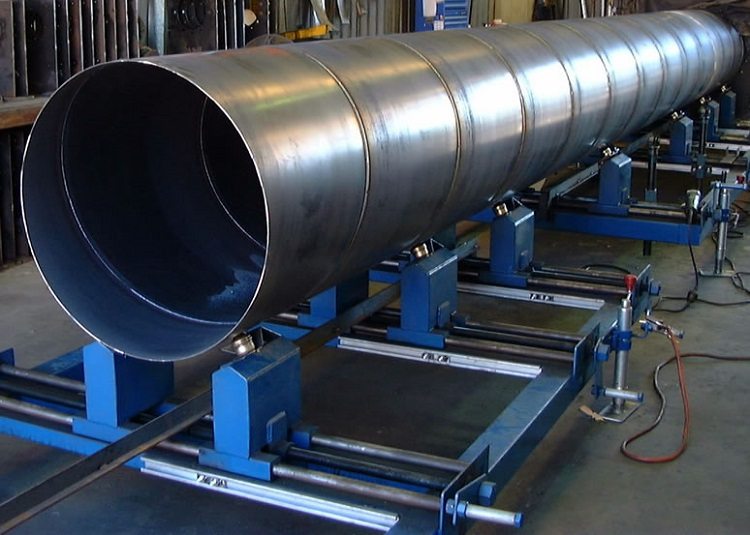

GOST 52079-2003. Document number 52079-2003 defines the standards to which welded straight-line and spiral welded steel products are subjected. Their diameter is in the range 114-1420 mm.Such dimensional pipes are used in the field of gas pipelines and pipelines for the transfer of oil and oil products. GOST 52079-2003 permits the transportation of only non-corrosive active products.

Welded steel products of large diameters according to GOST 52079 can serve as a means for transporting substances under constant pressure (working), not exceeding 9.8 MPa. The ambient temperature can drop to -60 degrees.

Important! GOST 52079-2003 officially lost its force on 01/01/2015. It has been replaced by GOST 31447-2012.

GOST 12336-66. The normative document GOST 12336-66 applies to closed-type profile products having a rectangular or square section. Since 01/01/1981 GOST 12336-66 was canceled, its functions began to perform TU 14-2-361-79. However, the provisions of document 12336-66 have remained relevant to this day.

GOST 10705-91 (80). Determines the technical conditions for creating steel electric-welded straight-seam pipes, the diameter of which is 10-630 mm. Steel pipes are produced in accordance with GOST 10705-91 (80) from carbon or low alloy steels. The scope of these structures is diverse: they are mainly used when laying pipelines for transporting water. The provisions of the standard do not apply to steel pipes used in the manufacture of heaters.

Pipes produced in accordance with GOST 10705-91 - the basis of domestic and industrial water supply systems

GOST 10706 76 (91). Gained distribution on electric welded steel pipes with a straight seam, used for general purposes. The diameter of the pipes according to document 10706-76 (91) may be in the range of 426-1620 mm.

GOST 10707 80. Regulates regulations for cold-deformed electrically welded pipes of various degrees of accuracy: ordinary, high and precision. Products according to the document under the number 10707-80 are available with a diameter of 5 to 110 mm. For the production of pipes, unalloyed (carbon) steel is used. Sometimes manufacturers of steel electric-welded (straight-seam) pipes indicate in the technical passport a link to GOST 10707 91. This is not a mistake, since the 1980 standard was extended in 1991.

In more detail, we will consider the main GOSTs below.

Assortment of steel square pipes: GOST 2591-88 (2006)

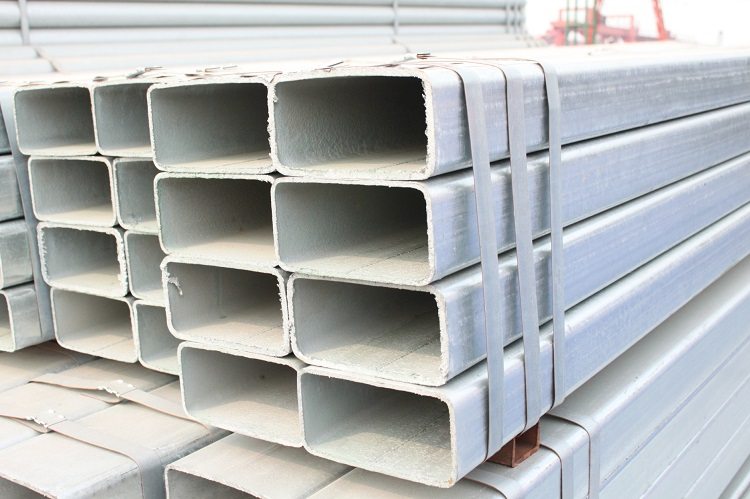

Rectangular and square shaped pipes are not widespread in the field of water and gas supply, but they are effectively used in construction as load-bearing and supporting structures. Thin-walled profiles are used in the furniture and advertising industry.

A weighty indicator of the quality of a square steel pipe is its mass: this position is also specified in GOST 2591-88 (2006). The mass index per 1 running meter with a steel density (black steel) of 7.85 g / cm3 should be from 0.269 kg - the thinnest pipe; 70.33 kg - for the thickest.

GOST 2591-88 for steel square pipes indicates that the value of the curvature of square steel should not exceed 0.5% of the length for products with a diameter of 25 mm and 0.4% for products with a length of more than 25 mm. At the request of the customer, this indicator can be reduced to 0.2%.

Deviations on the sides of square steel according to GOST 2591-88 can be in the plus or minus range. With normal rolling accuracy, a minus deviation of -2.5 mm is allowed (for dimensional products with a square side of 200 mm) to -0.5 (thin-walled products, the side of a square is 13-25 mm). And, accordingly, plus: from +0.9 mm to +0.3 mm.

Important! The range of steel square cold-deformed closed-type pipes is determined by GOST 12336-66.

The range of steel rectangular pipes is determined by GOST 8645-68. Products manufactured according to this standard can be hot-rolled, cold-drawn and seamless. From the point of view of strength, seamless designs win, but their cost does not allow them to be used massively.

Profile (both square and rectangular) steel pipes according to GOST are more often welded. Modern technological methods allow you to adjust the strength of the seam using induction currents, while the products will remain relatively inexpensive.Welds can be peeled and processed or left un peeled: it all depends on the further method of operation.

Galvanized profile pipes are produced in the same way: a steel tape with a previously applied protective coating is used. In some cases, galvanizing of finished products is applied. The profile tube is lowered several times into the reservoir with molten zinc.

GOST does not divide products into rectangular steel pipes into groups depending on the grade of steel used in the manufacture. GOST admits that in the production of shaped steel pipe black steel will be used, which is inferior to more expensive grades in presentable appearance and instability to corrosion.

A rectangular steel pipe according to GOST 8645-68 can have various sizes: the most popular on the lower side are 40 mm, at most - from 60 mm to 100 mm. Profile pipes, whose dimensions for the most part exceed 60 mm, have high bending strength with a relatively light weight, which makes them very popular in the field of engineering and construction.

Assortment of steel round pipes: the main GOSTs

Round steel pipe, manufactured in accordance with GOST, is mainly used in water and gas piping systems. Like profile designs, round pipes are produced in various ways, they are sutured and seamless. The group of round steel pipes covered by GOST is the most extensive and has a rather complicated systematization.

The assortment classifying a steel round pipe according to GOST mainly depends on the method of manufacturing the products.

Range of seamless steel pipes: GOST 8732-78 (91)

The production of hot-deformed seamless steel pipes in accordance with GOST 8732-78 (91) is a rather lengthy and complex process. This can explain the high cost of these products. Hot-deformed and cold-rolled seamless pipes are used in special conditions requiring excellent system strength: where any leakage can lead to irreversible consequences.

The raw material from which hot-deformed seamless pipes are made is a metal blank. From it subsequently the firmware process and after significant heating, a hollow cylinder is obtained - a sleeve. Initially, it has an irregular shape, but after passing the molding on the rollers, the hot-rolled round pipes become smooth.

The product is cut into segments from 4 to 12.5 meters, they can have a measured or unmeasured length. Hot-rolled steel pipes corresponding to the accepted GOST may have insignificant differences in wall thickness. Deviations in diameter are also allowed: if their values do not exceed those given in the table. The diameter tolerances allowed for the norm for seamless steel pipes according to GOST 8732-78 (91) are presented in Table 1.

Table 1

| Outside Diameter | Permissible deviations of steel pipes with manufacturing accuracy, mm,% | |

| Increased | ordinary | |

| Up to 50 mm | +/- 0,5 | +/- 0,5 |

| 50 to 220 mm | +/- 0,8% | +/- 1,0% |

| Over 220 mm | +/- 1,0% | +/- 1,3% |

Seamless steel round pipes can also be cold-deformed, in which case their norms will be governed by GOST 8734-75 (91). The production scheme resembles a hot deformation, with the only difference being that after passing through the press-flashing process, the metal billet is cooled by water.

GOST for cold-rolled seamless steel pipes repeats the provisions specified in the standard for hot-deformed seamless products. The document is subject to deviation in the dimensions indicated in the table.

table 2

| Initial dimensions, outer diameter | Permissible deviations, mm,% |

| 4 mm - 10 mm | +/- 0,15 |

| 11 mm - 30 mm | +/- 0,3 |

| 31 mm - 50 mm | +/- 0,4 |

| More than 51 mm | +/- 0,8% |

Assortment of steel welded straight-line pipes: GOST 10705-91

Specifications for the production of longitudinal steel welded pipes are dictated by GOST 10707-91.

The range of longitudinal pipes includes products of various diameters, including very large ones for industrial highways

The most important provisions of this regulatory document:

- round curvature electric welded pipe on a plot of 1 running meter, 1.5 mm is allowed for thermally processed products and for unprocessed - 2 mm. At the request of the customer, the value of curvature can be reduced in the first case to 1 mm, in the second to 1.5 mm.

- if the pipe will undergo heat treatment, at the request of the customer this process can take place in a protective atmosphere.

- the ends of a longitudinal seam welded pipe according to GOST 10707-91 are cut at a right angle, and also are cleaned from bumps and burrs.

A separate GOST was assigned for industrial gas and oil pipeline steel pipes. As mentioned above, GOST 52079-2003 applies to steel electric-welded straight-line pipes with a large diameter.

Important! Also in a special category are placed steel pipes (welded and seamless), manufactured for the motor industry. The provisions are regulated by GOST 12132-66. In any section of special pipes, curvature above 1.5 mm is not allowed. Regulatory document 12132-66 permits the release of products of only high or high accuracy.

Assortment of steel water and gas pipes: GOST 3262-75

Gas and water steel pipes were separated into a separate GOST, although in fact they are the most ordinary electric welded ones.

Electric-welded steel pipes for water and gas pipelines GOST 3262-75 commercially available in measured or unmeasured lengths. The range of segments in this case is from 4 to 12 m.

The curvature of water and gas pipes is allowed, but its value should not exceed two mm per linear meter, if the conditional passage is less than 20 mm. For VGP pipes with a conditional pass exceeding 20 mm, curvature is allowed at 1.5 mm.

Gas and water pipes have threads that can be short or long. When sending the pipe to the enterprise, a decrease in the internal diameter of no more than 10% in places of the rolled thread may be allowed. GOST presents the requirements for the thread on a steel electric-welded pipe, presented in the table.

Table 3

| Conditional pass | Number of threads with conditional pass | Thread lengths | Conditional pass | Number of threads with conditional pass | Thread Length (mm) | ||

| long | short | long | short | ||||

| 6 mm | No | No | No | 50 mm | 11 | 24 | 17 |

| 8 mm | No | No | No | 65 mm | 11 | 27 | 19,5 |

| 10 mm | No | No | No | 80 mm | 11 | 30 | 22 |

| 15 mm | 14 | 14 | 9,0 | 90 mm | 11 | 33 | 26 |

| 20 mm | 14 | 16 | 10,5 | 100 mm | 11 | 36 | 30 |

| 25 mm | 11 | 18 | 11,0 | 125 mm | 11 | 38 | 33 |

| 32 mm | 11 | 20 | 13,0 | 150 mm | 11 | 42 | 36 |

| 40 mm | 11 | 22 | 15,0 | ||||

In households, thin-walled VGP pipes are more often used. Their wall thickness does not exceed 4 mm, but it does not happen less than 1.8 mm. Thin-walled steel VGP pipes comply with all technical requirements and withstand pressure in the system without problems.

Steel pipe in PPU insulation in accordance with GOST 30732-2006

Separately, steel pipes insulated with PPU material should be highlighted. They have special technical characteristics that differ from ordinary steel products. GOST 30732-2006 also dictates the rules and procedure for the manufacture of shaped products.

Pipes with insulation are used when installing heating mains and water pipelines, if they are placed above the level of freezing of the soil

In accordance with state standard number 30732-2006, these pipes have a multilayer structure (pipe in pipe):

- Steel pipe. Directly working tube of circular cross section, which can be produced in any way. According to GOST 30732-2006, steel pipes in insulation can also be galvanized. In this case, their qualities will be even higher. The steel grade is selected depending on the method of further operation: the price of the product will also depend on this.

- Layer of PPU for isolation.It is a rather thick layer of insulating material of polyurethane foam, which is applied either by pouring liquid substance or by putting on a finished “shell” cover. PPU possesses the increased moisture resistance and promotes heat preservation. PU foam insulation can be normal or reinforced, depending on the weather conditions in the region.

- Containment shell. For the long-term safety of PPU-insulation, special protective shells made of low-pressure polyethylene (HDPE) or an additional layer of galvanized steel are used. The latter option will be more heavyweight and effective.

According to GOST 30732-2006, uninsulated copper wires are used as indicator conductors for pipes. This technology allows you to track leaks remotely.

The main advantages of a steel pipe in polyurethane foam insulation manufactured in accordance with the aforementioned GOST 30732-2006 are corrosion resistance (products do not require additional anti-corrosion measures), low heat losses (not more than 1-2%) and relative lightness (pipes in polyurethane foam -insulation is much easier than in isolation from PPM or APB). In addition, steel pipes with insulation according to GOST 30732-2006 can be laid without channels and wells.

At the same time, isolated structures according to document 30732-2006 have a number of drawbacks. The most significant are the flammability of the PUF insulation and the fairly rapid spread of corrosion in the event of damage to the protective sheath. Therefore, such systems require constant monitoring of the integrity of the material. If a certain insulated area is damaged, the entire network will need to be replaced: repair of a separate segment is not possible.

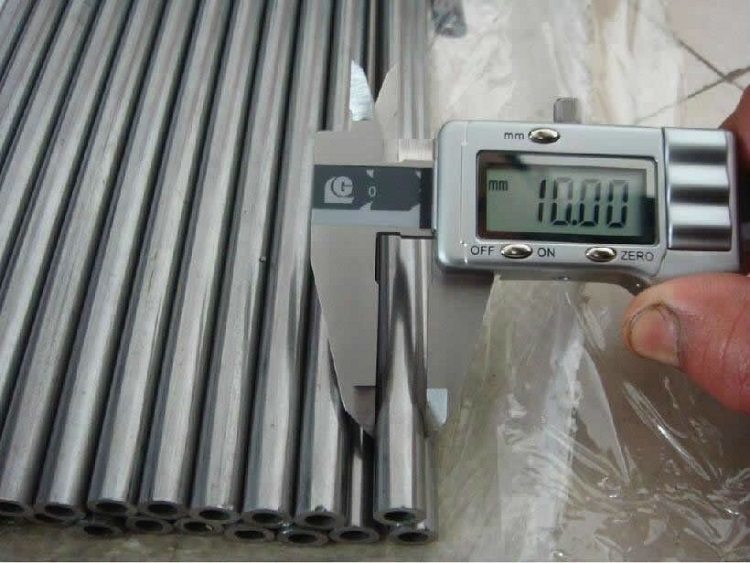

Range of steel precision pipes: GOST 9567-75

This group of steel pipes is subject to a separate GOST 9567-75, since special requirements are imposed on the production of products of increased accuracy. The product range includes precision steel pipes, different in manufacturing method and wall thickness. GOST regulates the following types of wall thicknesses of steel precision pipes:

- especially thin-walled pipes: ratio of diameter to wall thickness more than 40; wall thickness less than 0.5 mm.

- thin-walled pipes: the first indicator is less than or equal to 40; wall thickness - 1.5 mm or less.

- thick-walled pipes: the first indicator is from 6 to 12.5.

- extra-thick-walled pipes: the first indicator is less than 6.

Precision pipes are seamless. They are characterized by increased isotropic rigidity. Even thin-walled steel pipes according to GOST 9567-75 can be used in hydraulic and other rather complex and accurate systems.

Precision pipes are available in galvanized or phosphated, oiled surface.

Steel thin-walled or thick-walled precision steel pipe in accordance with GOST 9567-75 is available in measured or unmeasured lengths up to 8 m. Longer designs are made in agreement with the customer.

Other GOSTs for steel pipes

Regulatory documents also regulate other products and activities related to steel pipes. We give an overview of GOSTs that regulate the methods and procedure for installation work with steel pipes, fasteners (clamps) and connecting elements for steel products.

Steel pipe joints: welding

GOST 16037-80 - defines the requirements for welding steel pipes. The standard establishes the main structural elements for pipelines of various types of steels, typical sizes of welded joints of steel pipes with other products or fittings.

GOST 6996-66 - regulates the strength of welded joints of any metals. The provisions of document 6996-66 are relevant if steel structures are joined by welding with other metals.

Important! The normative documents 16037-80 do not apply to electric welded joints used in the production of steel pipes themselves.

Steel pipe fittings: fittings

The main method of joining steel structures is welding, but in some cases fittings are also used. They are welded, crimped or threaded.

Fittings are the common name for pipe fittings. There are several GOSTs for various steel fittings, namely:

GOST 8966-75 - dictates the rules for the production of metal direct couplings for the creation of steel pipelines. Coupling fittings may or may not have zinc plating. The strength of the coupling connection is achieved due to the cylindrical thread at the ends of the product. Fittings that comply with this standard create conditions for optimal operation of the pipeline transporting non-aggressive media with temperatures up to 175 degrees and under pressure not higher than 1.6 MPa.

Couplings according to GOST 8966-75 have internal diameters from 8 to 125 mm. It is allowed to manufacture couplings with an internal diameter of 150 mm according to the individual order of the consumer.

GOST 8967-75 - the standard applies to the manufacture of steel nipples also without coating or with zinc coating. Nipple fittings are equipped with a cylindrical thread and are mainly used for connecting water and gas structures. The requirements for temperature and pressure of the substance transferred through the pipeline remain the same as in GOST 8966-75.

The diameters of the nipples are in the range of 8-100 mm. At the same time, nipples with a diameter of 65 mm and 80 mm were not put into mass production, and are made after agreement with the customer.

Zinc-coated fittings-nipples are marked with the letter “C”. For example:

- nipple d32 GOST 8967-75 - without coating;

- nipple - TS d32 GOST 8967-75 - coated.

GOST 8968-75 - defines the technical specifications for steel fitting-locknuts with or without anti-corrosion coating. Lock nuts are screwed over the main nut, preventing self-loosening.

Locknuts with a diameter from 8 mm to 50 mm are produced in mass production. Locknuts with diameters of 65 mm, 80 mm, 100 mm are made individually.

GOST 8969-75 - dictates regulatory rules for the production of drives. These fittings have threads of different lengths at the end. Bends are designed for fixed joints (in strength resembling welded) elements of pipelines. On sale, you can find a size range from 8 mm to 50 mm in diameter, fittings-shields with marking 65 or 80 are available on request.

Elements for fastening steel pipes: clamps

Clamps of various diameters are used to fasten sections of pipelines to walls or fittings. They are metal U-brackets equipped with bolts for screwing into place. For steel pipelines, in very rare cases, plastic clamps are used, since basically they can not provide sufficient fastening strength.

When installing pipelines, not only clamps and staples can be used. Widely sought after for mounting are brackets, pads, pendants. Ensuring reliable attachment to the surface is not the only function of the fasteners. The clamps are also able to absorb vibrations and somewhat compensate for thermal expansion.

Metal clamps are made of galvanized steel strip. Sometimes a rubber coating is applied, which helps to absorb sounds.

GOST 24137-80 - applies to metal clamps for fastening steel pipes. This document considers fasteners, or rather clamps with a diameter of 15 to 240 mm.These accessories are suitable for securing communications for both pressure and pressureless. The standard specifies the requirements for the design and size of steel clamps.

For fastening steel pipes, it is better to use clamps with rubber gaskets - this reduces the noise level in the pipeline

Regulatory document 24137-80 also states that steel clamps must have a tolerance of parallelism and a misalignment of the axes of not more than 2 mm for any diameter.

GOST 24137-80 - repeats the provisions of the previous regulatory document, but considers unilateral clamps for fastening steel pipes.

When creating a fastener, you need to remember that the clamps should be located at a distance of at least 0.75 mm on a horizontal surface and at least 1-1.5 m on a vertical. For strong fastening of the bends of the structure, the distance between the clamps is observed at 150-200 mm from the corner.

The range of steel pipes and additional elements for them is a very wide area, including completely different types of products for all areas of application.