Many products made of modern materials managed to surpass the working qualities that a steel pipe possesses, but it is still ahead in terms of strength, resistance to temperature and pressure. The main reason steel pipelines are inferior to competitors is corrosion, but this issue also found a worthy solution. Galvanized steel protection made it possible to obtain reliable and durable material for the construction of a water supply system.

Galvanized products are used for water supply systems much less often than other types of pipes, due to the properties of zinc and installation features

Content

What is galvanizing

A galvanized pipe for water supply is a steel pipe, the inner and outer surfaces of which are coated with a thin layer of zinc - a metal that is not subject to corrosion. The longevity of the pipeline directly depends on the quality, strength and thickness of the applied coating. Galvanization is carried out in several ways:

- electro-galvanic - a method based on electrolysis (under the influence of electric current, zinc from the electrolyte settles on a steel surface), allows you to get an even layer of zinc with a thickness of 10-25 microns, but not the highest adhesion and porosity;

- hot dip galvanizing - a steel pipe with a carefully polished, cleaned surface is immersed in a container with molten zinc (450aboutC), which envelops it, forming a dense, 40-200 microns thick coating. The surface may have sagging, threading;

- thermal diffusion - a method of obtaining the highest quality coating by treating a steel pipe with zinc vapor under the action of high temperature in a closed container. Zinc particles are “embedded” in the structure of the steel surface, providing reliable adhesion. The layer is dense, uniform, durable.

Galvanized pipes for water supply have several advantages:

- strength, resistance to loads, water hammer, mechanical damage, wear resistance;

- the roughness of the inner surface is reduced, which increases the throughput and significantly slows down the overgrowing of the pipe section;

- resistance to corrosion;

- operating temperature 20aboutC - 140aboutWITH;

- working pressure 1.6 MPa;

- minimal thermal expansion, pipeline construction stability;

- average life of 20 years.

As a rule, in a domestic and industrial domestic water supply, a round galvanized pipe with a diameter of 20-160 mm from carbon steel of ordinary quality or carbon high-quality structural steel, seamless or electric-welded, is used. The wall thicknesses are ordinary (2.5-4.5 mm), light (2-4 mm) and reinforced (4-5 mm). The mass of the tubular product after galvanizing increases by 3%. Length measured, multiple measured (4-12 m).

Galvanized pipes for cold water supply with an uninterrupted supply of drinking water are safe for human health, since the maximum concentration limit of zinc does not exceed 5 mg / l (daily norm of zinc is 10-15 mg).

Important! When the concentration of zinc in drinking water is above 5 mg / l, its taste becomes astringent, opalescence is visually manifested.

Galvanized pipes are used to organize autonomous water supply during the construction of wells, but this is not provided for by SNiP and GOST. There is not enough water exchange inside the well; due to the influence of carbon dioxide, the water composition is significantly deteriorating due to chemical reactions. Soil environment does not exclude electrochemical corrosion at the joints.

Service life of galvanized water pipes

Galvanized water supply has proven itself in cold water supply with a constant flow of purified water. Corrosion resistance is significantly lower for hot water supply systems, since temperature fluctuation over time leads to the destruction of the zinc layer. With an increase in water temperature from 60aboutC to 80aboutWith the corrosion rate increasing by 5 times, the zinc layer changes polarity relative to steel, becoming a cathode porous coating from the anode, which leads to ulcerative corrosion. The life of a zinc-coated pipeline is highly dependent on the quality of the water.

Replacement of galvanized water supply elements may be required after 15 years of operation, if the composition of the water is aggressive for zinc coating

Important! Galvanized pipes are designed to work with cold water, the acid-base balance of which is pH 7.5 - 8.5, chloride content up to 100 mg / l, sulfate content up to 150 mg / l, saturation index I≥-0.5, oxygen up to 3 mg / l, copper up to 0.04 mg / l.

The combination of copper and galvanized pipelines is excluded, since the ongoing physicochemical processes of the interaction of these metals will lead to ulcerative corrosion of the zinc-coated pipes. The presence of 0.1 mg / l of divalent copper in water will inevitably cause damage to the pipeline.

The increase in the corrosion rate of galvanized steel is directly proportional to the cubic root of the water flow rate (from 0.3 to 0.95 m / s) inside the water supply. In multi-storey buildings, pumps are used to supply water, with an increase in pressure in the water stream, the level of oxygen rises, and therefore, zinc layers are washed off. Durability in this case depends on the thickness and quality of the zinc layer, optimally 400 grams of zinc (layer thickness 45 μm) should be spent on 1 m of pipe.

It was found that in the first period of the average service life (30% of the 20-year period) of pipes with galvanization, significant repair work or replacements are not required. About 15% of replacements are required during the period of 30-80% of the service life and 60% of replacements in the period of 80-120% of the average term.

The life of a galvanized water supply system, as can be seen, depends on many factors and can range from 15 to 40 years. Nevertheless, it should be noted that galvanization extends the work of steel pipes by 4 times.

Galvanized water pipe connection

Connection of galvanized pipe is possible by welding or threaded method. Obviously, the violation of the integrity of the protective layer leads to corrosion and the joints are exposed to this risk to a large extent, therefore, the installation of these systems requires a special approach.

The threaded connection is used for mounting round galvanized pipes. Steel pipe product with factory-applied thread at the ends after diffusion galvanizing is fully protected and ready for threaded connection using galvanized fittings (couplings, nipples, reductions, plugs, adapters, angles, etc.). The joint is sealed by winding tow with painting. During hot-dip galvanizing, the thread often swims and has to be restored again. Docking with a thread, made in accordance with all the rules, is reliable and airtight, safe for water supply, does not corrode, and is convenient for further replacement and repair.

The welding connection for galvanized products was previously considered inapplicable, since at high temperature the zinc burned out, and the junction became vulnerable.In addition, zinc vapors lead to serious poisoning. However, today there are several known methods of welded joints of steel products in galvanization without damaging the protective coating. The welding method is suitable for installation of all types of pipes, both round and profile, of any section.

The basis for welding galvanized products is to prevent the evaporation of zinc from the surface of the steel. To do this, a flux layer is applied to the pipes at the junction, which prevents the protective layer from burning out. The filler rod is molten by the torch flame, forming a weld. Zinc melts, but does not fade, then solidifies again. This type of connection is used for installation of the water supply system, the remains of the flux inside are gradually washed out with water without harm to drinking qualities.

Also, during welding on a semiautomatic device, liquefied food carbon dioxide is used as a protective medium to preserve zinc. In the weld zone, the zinc layer is stripped, since its oxides contribute to the spatter of the electrode, which makes the weld porous. For gas-electric welding of thin-walled galvanized pipes (up to 5 mm), overhead copper rings are used, which are then removed, while maintaining the integrity of the zinc coating.

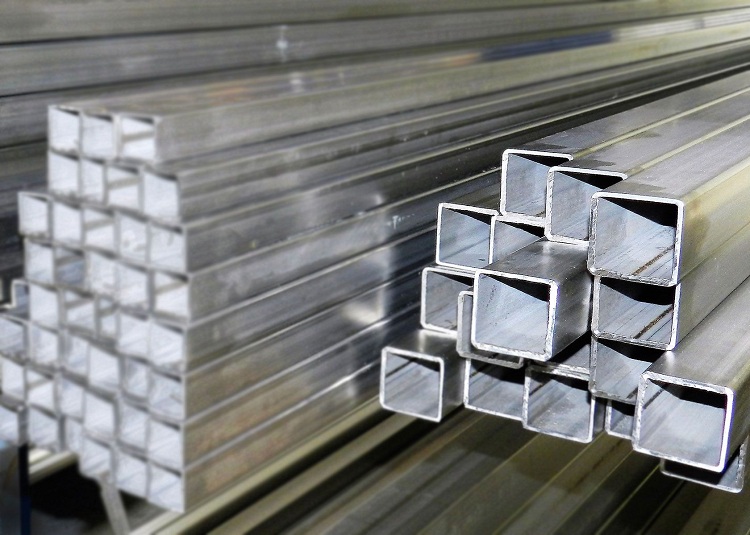

Galvanized Profile Tubes

Steel cold-rolled and hot-rolled profile tubular products of square, rectangular and other sections are also available with a protective zinc coating from corrosion processes. They can be welded straight-seam or have no seam; thin-walled (light 1.5mm, 0.85kg / m), reinforced (high strength from 2mm, 1.1kg / m).

A profile pipe is indispensable in the construction of frames, strong metal structures of any complexity due to its qualities: lightness, resistance to static, dynamic loads, kink, bend, it is easily mounted. All these advantages are greatly enhanced by galvanizing, making products more durable, resistant to corrosion and aggressive environment.

A zinc coating is applied both in the production environment and at home. The highest quality resistant coating is obtained in the manufacture of a galvanized profile pipe in an industrial way (hot, galvanic, diffusion galvanizing). The product is galvanized in finished form or bent from a steel sheet already coated with zinc, and then the seam is welded and galvanized. Cold galvanizing is carried out by painting the pipes with a special solution containing zinc powder, this coating can be done independently, while protecting only the outer surface.

Profile pipes have a wide assortment and range of sizes, in any field it is applicable due to its versatility, in galvanization it has an aesthetic appearance without additional staining. Installation of such pipes is carried out quickly by welding or bolt screed.

The protection of water pipes by galvanization has proven to be quite effective, the life of the steel pipe is extended from 5-9 years to 15-20 years with proper operation up to 35 years. Much depends on the quality of the pipes, the composition and method of applying the protective coating, all this should be paid attention to. Often, galvanizing protects the pipe assortment from corrosion during product storage, and it is not designed for operational loads as a water supply. Therefore, for water supply systems, galvanized pipes should be selected according to their intended use.