Of whatever materials the pipeline is built, no matter what load it is designed for, whatever its functionality, it must be durable and reliable. Today, polypropylene pipes with insulation have become a worthy alternative to metal pipes, and they are more suitable for plumbing in the private sector. This is due to the fact that the water in it remains clean - due to the absence of rust and other deposits in metal pipes. These pipes have a lot of advantages, so their demand is increasing - an ever larger segment of the market is allocated to this variety.

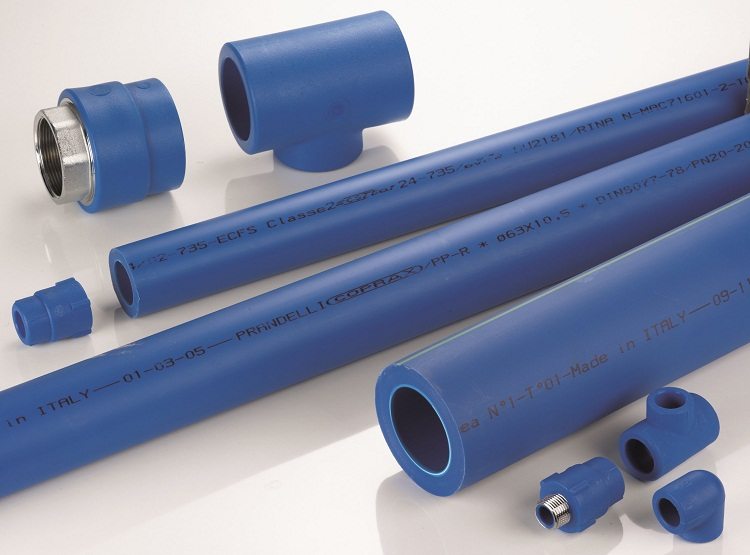

Manufacturers offer many types of polypropylene pipes for the installation of plumbing and sewer systems

Content

- 1 Polypropylene Pipe: Important Material Information

- 2 Important features reflected in standard requirements and certification

- 3 Operational load classification

- 4 Positive characteristics of the polypropylene pipeline

- 5 Rating of the largest suppliers and assortment of polypropylene pipes manufactured by them

- 6 Recommendations for the selection of polypropylene products

Polypropylene Pipe: Important Material Information

When chemists invented plastic, it became a big breakthrough in technological development. Its new varieties periodically appear in the production of communications, in construction and in various spheres of economic activity. Among the largest inventions in the field of plastics was the invention of plastic and its varieties. The latest development of the technologists was the so-called “Rand of the copolymer of the 3rd type” or a high-temperature variety of the copolymer close to polyurethane foam, it is better known as polypropylene.

A durable and lightweight thermoplastic in practice has shown many positive characteristics, including inertness (resistance to most chemicals) to alkaline and acid reactions. Today, polypropylene of excellent quality is given by enterprises in Finland, Italy, and Germany. In construction supermarkets you can find their products with the appropriate labeling, insulation and a large assortment.

It is interesting! The uniqueness of polypropylene water pipes is that their flexibility and ductility allow water to freeze inside without changing its shape and without reducing the properties of products. They tolerate a short-term temperature jump inside up to 110 ° C. And although such pipes are not suitable for hot water and other media for prolonged use, in normal mode pipelines from them are used for water supply in the range from -10 ° C to + 95 ° C.

Polypropylene pipes are also applicable for the installation of heating, you just need to remember that for these purposes you need to choose reinforced products

Important features reflected in standard requirements and certification

- Polypropylene has an extremely low density, relative to a number of polymers and plastics, according to GOST 15139 - about 0.9 g / cc. But this does not prevent gas and other polypropylene pipelines from having sufficient hardness and wear resistance.

- During the likely stretching, according to GOST 11262, indicated in the certificate, the yield strength of the PPRC copolymer is 24-25 N / sq. Mm. Ultimate elongation is possible, according to GOST 11262 - about 50%, in the test area.

- The polypropylene pipe begins to melt or deform at t ° above + 150 ° C, as indicated in GOST 21553.But outside of + 110 ° C, the flexible pipe begins to deform when overheated, softening occurs at + 140 ° C. However, within + 90 ° C, hot water supply is acceptable.

- The thermal conductivity at a normal water supply t ° up to 20 ° C is 0.24 W / m. At the same temperature, the specific heat of the pipe is 2 kJ / kg (GOST 23630).

- The amplitude of tensile strength, according to GOST 11262, is within 34-35 N / sq. Mm. This is indicated in the certificates for polypropylene pipes of various diameters.

- The linear expansion coefficient of GOST 15173 is 0.15 mm / m ° C, this is with an external diameter of products from 15mm to 125mm.

- Resistance to the majority of aggressive environments is confirmed experimentally, and the destruction of the structure is likely only at high temperature, in combination with caustic acids.

- Typically, pipes for water supply of PP are used indoors at a positive t °, but the indicator of their frost resistance is within -15 ° C, and this is enough for adjacent rooms with heated rooms. But it is better in this case to choose models in isolation of PPU.

- Allowable pressure is up to 25 atmospheres, depending on the modification, and these indicators are indicated in the certificate and on the marking of the assortment of gas and polypropylene pipes for water supply.

- The permissible bending radius of tubular products made of PP is proportional to their diameter, which depends on the presence of PPU-insulation and the type of reinforcement component. Limit indicators - for polypropylene products with aluminum foil without perforation.

Note! All these properties are guaranteed for polypropylene pipes with a certificate of conformity.

Operational load classification

According to the domestic standard for thermoplastics products and their fittings used in heating, water supply and gas pipes, there are 6 classes of operation. They are indicated in the norms of GOST 521343 (2003), where the parameters are oriented to the nominal temperature of gas and water.

- Use of PP in cold water supply (labeling ХВ).

- Use in low-temperature floor heating systems (up to 60 ° C).

- Use in water supply with warm water up to 60 ° С.

- Use in hot water supply up to 70 ° С.

- Use in floor systems without PPU isolation and for radiator heating of low temperature - up to 70 ° С.

- Use for the heating system in radiators at high temperature - up to 90 ° C.

Attention! The technology for laying polypropylene communications has long been developed, it is simple if there are suitable fittings and a knife designed for cutting soft pipes. Installation resembles the laying of metal-plastic pipelines. The popularity of flexible water conduits with PPU insulation and without it is growing among large construction organizations and ordinary consumers - this is due to the low weight and simple docking.

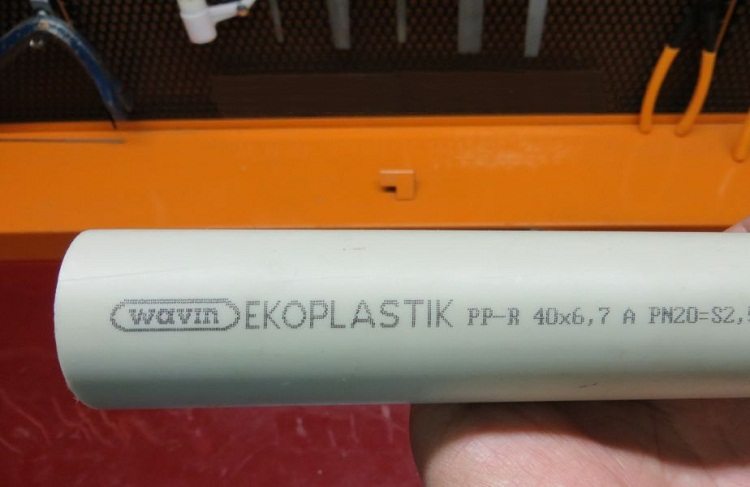

An extensive assortment of polypropylene pipes has its own indexing. The letter marking on the pipes is indicated by an additional letter, as their quality parameters increase - PP, PP-R, PP-RC of the 3rd type (for hot water supply and heating) and universal PP-RCT.

Certified polypropylene pipes marked PP-RC are general-purpose products. These are communications and heating, gas and water supply, specific needs in agriculture and industry.

Polypropylene pipes in polyurethane foam insulation are also classified into 4 categories, according to the working pressure parameters:

- PN10 brand products - the internal pressure of the heat transfer fluid is permissible within 10 atmospheres, which is used at low temperatures, up to 45 ° C.

- PN16 brand products - the figure shows the permissible pressure up to 16 atm. In this case, the permissible temperature of the coolant or gas is within 60 ° C.

- The most demanded standard is PN20 brand products, with a liquid medium supply up to 95 ° С, gas - within 20 atm.

- PN25 brand products withstand the highest pressure - up to 25 atmospheres. They provide the supply of hot water or gas (steam) up to 95 ° C, thanks to the PUF insulation and the minimum rate of linear expansion. The most common pipe format is with an outer diameter of 20 to 40 mm.

For heating, purchase products in insulation with continuous foil reinforcement; they have a slight linear expansion during heating and gas diffusion. This variety is designated PN, but they have different types of reinforcement, for example, foil (aluminum) or fiberglass. Also inside is:

- perforated tape;

- monolithic layer;

- fiberglass mesh.

Positive characteristics of the polypropylene pipeline

The invention of the random PPRC copolymer has become revolutionary in the field of flexible materials. Polypropylene pipes for gas and liquid media differ in a number of unique properties that give advantages over other materials:

- do not form rust and dirty sediment, the water inside is always clean;

- a long period of operation (even with susceptibility to expansion, the inner diameter of the products is stable);

- inertness of the material, the absence of chemical reactions inside the pipe, liquid substances and gas do not change the composition during transportation;

- resistance to temperature extremes, internal pressure and external deformations;

- polypropylene pipes have a longer service life than metal and flexible analogues;

- minimal thermal conductivity, condensation does not form on the surface and insulation;

- excellent noise absorption (the flow of water inside does not create such noise as in metal-plastic pipes);

- resistance to vibrations that destroy harder materials;

- quick installation according to the technology of socket welding (in the presence of special scissors), fitting do not require additional insulation;

- profitability during transportation - the weight of a polypropylene pipe is several times less than the weight of metal pipes;

- products have certificates and markings on each product range;

- the operational period indicated in the documentation for polypropylene pipes exceeds the same indicators for metal and plastic (up to 50 years);

- ease of maintenance, does not require inside cleaning and does not need to be painted on the outside for heating, water supply. Paint does not require gas pipes made of polypropylene.

Attention! Even if a comparison is made between metal-plastic and polypropylene pipes, many indicators with a random PP-RCT copolymer will be higher.

Rating of the largest suppliers and assortment of polypropylene pipes manufactured by them

The production of polypropylene pipes has long been established by foreign enterprises. It has already been proven that eco-friendly PPRC does not harm the environment, even when disposing of waste from scraps and used fittings. The properties of the random copolymer make it the most valuable in the conditions of global environmental pollution. A harmless compound was obtained experimentally - through the introduction of ethylene gas molecules into the structure of propylene, which gave a new modification of plastic with unique qualities and insulation.

In the vast majority, polypropylene pipes have a certificate of conformity and marking. They are produced by industries with an impeccable reputation in the world market. Although the technology is slightly different, they compete in quality, and the best products deliver:

- German companies Banninger Reiskirchen (low-weight polypropylene of the highest quality PP-RCT by Wefatherm).

- Czech companies WAWIN Ecoplastik, which have become pioneers in this industry, however, the high price makes their products less popular in our country.

- Italian Valtec companies offer metal-plastic and PP pipes for water supply with an optimal price ratio.

The most popular polypropylene pipes in our market are from Pilsa, Vesbo and TEBO and others. These are Polish, Chinese, Finnish and Turkish manufacturers. All of them offer a good quality assortment, but their marginal parameters are lower than those of German and Italian.

Tip! When shopping, look not at the manufacturer, but at the labeling and technical parameters of the products. It makes no sense to overpay for high-quality pipes for gas or hot water if you intend to make a pipeline for cold water without high pressure. But the low cost from a dubious manufacturer cannot guarantee resistance to temperature and pressure extremes.

When choosing pipes, it is worth giving preference to a well-known brand, since saving on materials for water supply can turn into the need to replace the entire system

Recommendations for the selection of polypropylene products

- When buying, pay attention to the pipes themselves and to the accessories - couplings, fittings, tees, etc. Combined products where a metal frame or an insert with a thread is soldered, despite the greater weight, are reliable. They provide a transition from PP to metal-plastic pipes or metal parts (radiators).

- In any pipeline in PPU-isolation and without it, a short-term increase in load parameters is possible, including water hammer, steam pressure and temperature changes. It is better to choose pipes with high load indicators.

- In individual heating systems, the pressure is usually lower than in urban houses, but pipes marked PN20 are quite enough.

- A reinforced polypropylene pipe is considered universal if the pipeline systems will serve autonomous water, gas and heat supply. For hot heat carrier - only reinforced productshaving a little more weight. When laying in the ground or in an unheated room, you should insulate the pipes, or buy products with PPU insulation.

Attention! The guarantee of long-term operation is provided not only by imported products with a certificate and impressive marking parameters. High-quality installation and compliance with the parameters of the workload is important.

Do not take up installation of pipes for water supply or a gas pipeline if there is no experience in this matter.

The unique plastic random copolymer of PPRC polypropylene is an excellent alternative to metal-plastic and metal pipes. The widespread use of copolymer pipelines ensures the purity of the liquid medium and gas. Due to the internal insulation and the fact that these pipes do not rust, the water inside is clean. Those who care about the health of their family are advised to pay attention to the water supply system from this material.