The durability of the water supply system largely depends on the quality of the materials used during its installation. Today, polymer products are widely used. Polyvinyl chloride - a material consisting of carbon, hydrogen and chlorine. It is possible to influence the properties of finished products by introducing impurities into it during their manufacture. Polyvinyl chloride is not toxic and allows you to transport all kinds of liquids, acids (sulfuric, phosphoric, hydrochloric) and oils.

Content

Characteristics of PVC pipes

Pipes are divided into polyvinyl chloride (PVC) for cold water supply systems and products from chlorinated polyvinyl chloride (CPVC) for hot water supply.

Important! The use of special stabilizers increases the impact resistance and frost resistance of pipes, preserves the integrity of the structure under mechanical loads.

For water pipes, pressure products are usually used. One of the most important properties PVC water pipes is the ability to work with high pressure in the network. Water supply is organized by the use of pressure products, the production of which is based on documents: GOST R 51613−2000; TU 2248−056−72311668−2007.

According to the classification, the division of pipes occurs into 4 markings:

- size: large, medium, small;

- bending radius: rigid, flexible, very flexible;

- type of laying: external, internal;

- working pressure: pressure, non-pressure, for rarefied environments.

The device of external water supply systems is carried out by pipes with a diameter of 9-63 cm at a working pressure of 6-10 bar. In non-pressure water supply systems, PVC products with a diameter of 11-63 cm at a pressure of not more than 0.16 MPa are often used.

The standard pipe length is 1; 2; 3 and 6 m, the diameters are very different - from 1.2 to 63 cm. If necessary, they are cut with special scissors into the required lengths and cleaned.

When choosing pipes, it is necessary to pay attention to the wall thickness, which should be the same over the entire circumference of the section, the absence of roughness and sag.

Technical characteristics of PVC products

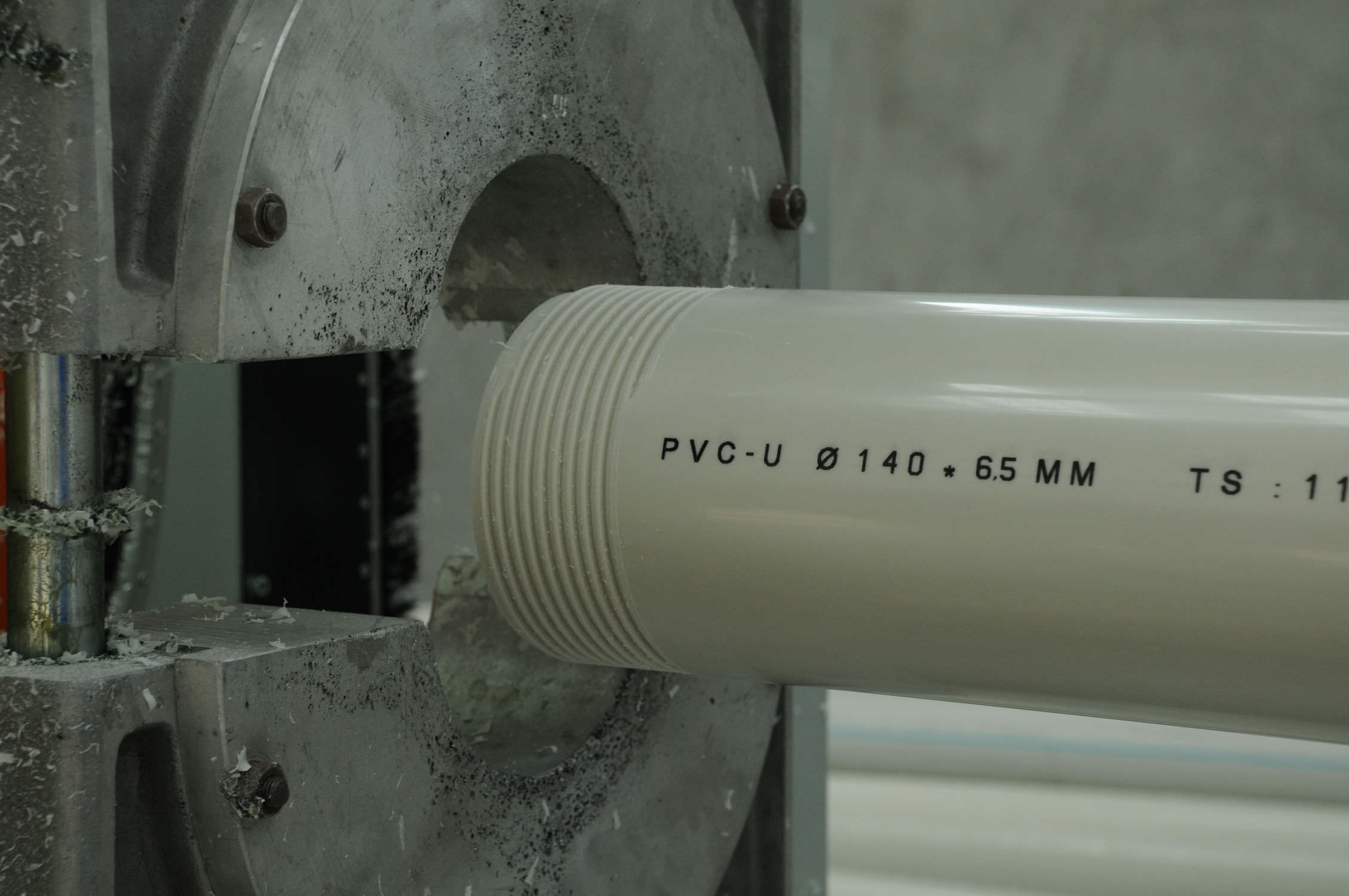

The choice of pipes is carried out by marking, which is applied to the surface of the pipe and reflects its main parameters. According to international standards, PVC pipes for water supply are equipped with a bar code indicating the main characteristics:

- SDR is the ratio of the outer diameter to the wall thickness;

- pipe wall thickness;

- outside diameter;

- conditional pass;

- nominal pressure;

- ring stiffness;

- maximum pipeline pressure.

The manufacturer applies the technical data of each type of pipe to the outer surface of the products

In the regulatory documents for the manufacture of pipes, numerous parameters and requirements for such products are given. For PVC pipes, the main ones are several indicators, which are presented in the table.

Table 1

| Index | Value |

| life time | 50 years |

| density | 1.4 g / cm³ |

| flammability | incombustible |

| thermal conductivity | 0.15-0.25 W / (m * ° C) |

| estimated linear expansion coefficient | 0.07 mm / (m * ° C) |

| change in pipe length after heating | no more than 5% |

| tensile strength of pipes d> 1.2 cm | not less than 49 MPa |

| elongation at break of pipes d> 1.2 cm | not less than 25% |

| opacity | no more than 0.2% |

PVC water pipes have a safety margin of 1.25 units for cold and 1.75 units for hot water. For outdoor water supply systems, pipes with SDR 41–17 for pressure values of 16–6 bar are most often used. They are gray in color and differ from sewer pipes by the type of bell.

The main advantages and disadvantages

PVC pressure pipes for water are lightweight and are sold at a relatively low cost. They have a bell with a sealing ring, which allows to obtain a tight connection without the use of an additional seal. For installation, welding machines and sophisticated tools are not required. Due to its simplicity, installation can be done by hand.

Since pressure pipes are not susceptible to decay and corrosion, the incoming water is clean. Products made of polyvinyl chloride are characterized by reduced flammability. The inner surface of PVC pipes is always free and clean, since there is no accumulation and deposition of salts on their walls. This property increases the operational life of products.

Drinking water can be transported through PVC pipes. A wide variety of elements allows, if necessary, to arrange a curved water main. Bacteria do not multiply inside such pipes. There are 12 times fewer bacteria per 1 cm2 of PVC pipe than in a similar section of a polyethylene pipe, and 9 times than in a polypropylene pipe. Polyvinyl chloride pressure pipes are resistant to ultraviolet rays, which allows them to be used for outdoor water supply.

Among the shortcomings of PVC pipes, it is possible to single out the impossibility of using them in hot water supply or heating systems. The maximum short-term heating temperature for them is 65 °, and the optimal temperature is 45 ° C. Pipes require good insulation at low temperatures (less than -10 ° C).

Important! PVC pipes for water supply can not be burned, since chlorine is released during combustion.

There may be difficulties in joining PVC pipes with products from other materials.

PVC pipe joint

There are three ways to join PVC pressure pipes for water supply:

- using couplings;

- into the bell;

- flange connection;

- cold welding.

To connect PVC pipes with the adhesive method, it is necessary to first check the elements for compatibility. To do this, just insert the pipe into the appropriate fitting. Further, the required length of the product is cut with scissors or a hacksaw for metal. The end of the pipe is cleaned with a file or a beveling knife. After blowing and degreasing, glue is applied to the connected surfaces.

The pipe is inserted into the fitting and rotated 1/4 turn so that the glue is evenly distributed. The connection is fixed for 20-30 seconds, and the docking process itself should not exceed 1 minute in time. After that, the remaining glue is removed. When using pipes with a diameter of more than 50 mm, tightening devices are additionally used.

To connect pipes with a diameter of 5-11 cm, couplings are used. The product of the required size is cut, attached to the coupling and marked on it. The inner surface of the coupling and pipe is lubricated with glue and they are fixed according to the marks. The pipe must fit 2/3 into the corresponding fitting.

The bell-shaped method of connection is simple and quick. Docking points are lubricated with a silicone compound and connected by introducing the pipe into the socket to the mark of the pipe. It is important to observe the alignment of the elements.

Pipeline installation

Installation of the water supply system is carried out in several stages.First, it is necessary to draw up a clear and detailed diagram of the future network, indicating the locations of the devices and the necessary elements with their size and quantity. It is important already at the planning stage to have a good idea of how pressure head water pipes will pass.

Before installation, you need to prepare pipe segments of the desired length and connecting elements to them

Further, the system is disconnected from the water supply and the old pipes are dismantled. To install PVC pipes you will need scissors for cutting them, a cleaner, glue, special brushes for applying glue and cleaning surfaces to be glued together.

PVC pressure pipes of large diameters are cut with a roller cutter. Care must be taken to maintain a right cut angle with respect to the axis of the product. The ends must be machined with a knife for chamfering or filed with a file.

Before gluing the parts of the pipeline, the connected parts are lubricated with a cleaner. The process of connecting the pipes is based on the dissolution of the upper layers of the joined surfaces with glue. Materials penetrate each other's structure, forming a monolithic joint, characterized by tightness and strength.

Note! If the connection is made correctly, an even layer of glue will appear at the junction of the fitting and the pipe, which is wiped with a cloth.

It is better to use glue, which is recommended by the manufacturer.

Feature of fittings

Shaped parts for pressure head water supply systems have a wide range of models and standard sizes. Based on the characteristics of the pipeline, the corresponding types of parts that perform certain functions are determined.

The coupling is used for straight sections of the pressure pipe from PVC pipes. It is a double bell and is used for joining pipes and pipes that have smooth ends. The repair sliding sleeve has sinuses under the rubber sealing ring on both sides. Due to its structure, it slides along the pipe from the outside and allows repair work in hard-to-reach places.

Tees are used to connect polyvinyl chloride pipes with products from other materials or to branch a pipeline. For use in pressure networks, they are equipped with trilateral sockets.

On some sections of water supply systems, pipes are installed. They join PVC pipes with valves or a system of pipes made of other materials. If the diameter of the pipes changes, adapter pipes are installed.

If the direction of the water flow deviates or the network configuration changes, bends or bends are used. They have one end smooth, and the other with a bell. There is also the possibility of inserting pipes from polyvinyl chloride into the pipeline. For this, saddle bends are used. The insert is carried out using a conical or cylindrical threaded connection. The ends of the pipes can be closed with blind PVC flanges.

Thus, polyvinyl chloride pipes are the most profitable and suitable choice for the installation of water supply systems. Their quality, reliability and variety of shapes allows you to lay a water pipe with a long service life.