Water supply, like any other system, sooner or later can fail. As a rule, the breakdown of this communication occurs as a result of its wear and tear. However, other options are possible: mechanical impact, increased pressure in the system, etc. The sequence of troubleshooting communication depends on the material from which it is made, as well as on its type.

Breakdowns in the water system occur for various reasons, but most of them can be repaired with your own hands.

Content

Types of breakdowns

Breakdowns in water utilities are divided into the following types, depending on their nature:

- from time to time there may be short interruptions in the water supply. In some cases, a break can be a long one;

- complete disappearance of water in communication;

- pressure drop in the network;

- the appearance of noise in the system that is not characteristic of the usual movement of water through pipes;

- the appearance of condensation on water pipes;

- clogging in the pipeline;

- failure of communication elements.

Important! Metal pipelines are much more likely to fail, as they have poor resistance to corrosion. In addition, the inner walls of metal pipes are not as smooth as those of plastic counterparts, so salt deposits accumulate on them. This leads to a narrowing of the lumen of the pipe, until it is completely blocked.

Low pressure is a fairly common problem, due to which there is a cessation of the flow of water into the taps. This leads to the fact that residents of high-rise buildings simply stop receiving water.

To measure the pressure in the water supply, a special device is used - a manometer. If it registers low pressure readings, it is necessary to open the dampers in the wells and at the entrance to the communication. Also, in the water supply system, various equipment may fail: fittings, pumps, etc. In the event that a malfunction of the valve in the water supply network is found, an inspection of all its types should be carried out: safety, shut-off, water-folding and water-regulating.

Most breakdowns lead to a drop in pressure in the system and a decrease in the pressure of water in the taps

In order to identify a pump breakdown, a pressure gauge is used, which must be installed at the pipeline inlet to the building and after the pumping equipment. Thus, it will be possible to detect the difference in pressure and diagnose the problem.

What pipes are used in the repair of pipelines?

To replace the damaged sections of the water supply, pipes of different material are used. Consider the materials from which they are made:

- polypropylene (PP);

- polyethylene (PE);

- metal-plastic;

- metal (steel or cast iron).

Consider the main advantages of pipes that are made of polypropylene:

- high rates of sealing compounds;

- high wear resistance;

- resistance to the harmful effects of corrosion;

- resistance to aggressive chemicals;

- smooth inner walls that prevent the formation of salt deposits;

- ease of installation;

- low cost;

- long service life.

Parts made of polyethylene, as a rule, are used only for laying external water supply networks. Consider the main advantages of plastic products:

- budgeting;

- the availability of parts and their diversity;

- long service life of polyethylene products;

- repair of an external water supply system using polyethylene parts is simple.

Polyethylene pipelines do not tolerate high temperatures, therefore they are used only for communications that transport cold water. They are also actively exploited for the installation of sewer networks. Sewer pipe made of polyethylene, as a rule, is pressureless. This means that the drains in it move obliquely in a natural way. Repair of water supply and sewage from polyethylene is carried out mainly with the replacement of damaged areas.

Metal-plastic pipelines are incredibly popular today. They combine three layers: the outer and inner layers are represented by a polymer material, and in the middle is a metal layer. Such products are very in demand in localized repair work.

Among the advantages of metal-plastic pipes are:

- low cost;

- resistance to corrosion;

- resistance to aggressive chemicals;

- ease of installation.

But it is worth noting that individual elements of metal-plastic communications have lower reliability indicators of fastening and tightness than plastic analogues. In addition, at high temperatures, the design of such pipes can lose its density.

Products made of different metals are not so popular today, as they are quite cheap and are characterized by complex installation and corrosion resistance.

How to eliminate water leakage?

Water leakage is the most common type of breakdown that can occur in any area of industrial or private communication.

Important! Before starting repair of a water pipe leak, it is mandatory to shut off the water in the system. Next, the leak should be dried and only after all these manipulations can we proceed directly to eliminate this breakdown.

To combat the leak, there are several ways that you should pay attention to:

- Use of special sealant or epoxy glue. In this case, before starting to repair the leak, remove rust around the damaged area. It is recommended that the surface be freed from rust within a radius of 5 centimeters around the leaking area. Next, apply sealant. If epoxy glue is used to eliminate the leak, a bandage will be required. After that, it is recommended to use the water supply system not earlier than after 12 hours.

- A special device, the flange, will help to cope with the leak. It is worth noting that the use of the flange is a temporary measure, however, in this case, the leak will be eliminated for a long time. A flange is a product that can be reused.

- And finally, another method to combat leakage is a pipe clamp of a larger diameter. To do this, make an incision at the breakthrough site and treat the area with glue. Then a pipe is installed in this place, which will perform the function of a clamp.

Repair of metal pipes for water supply

There are several common methods for repairing various breakdowns in metal communications. Consider them:

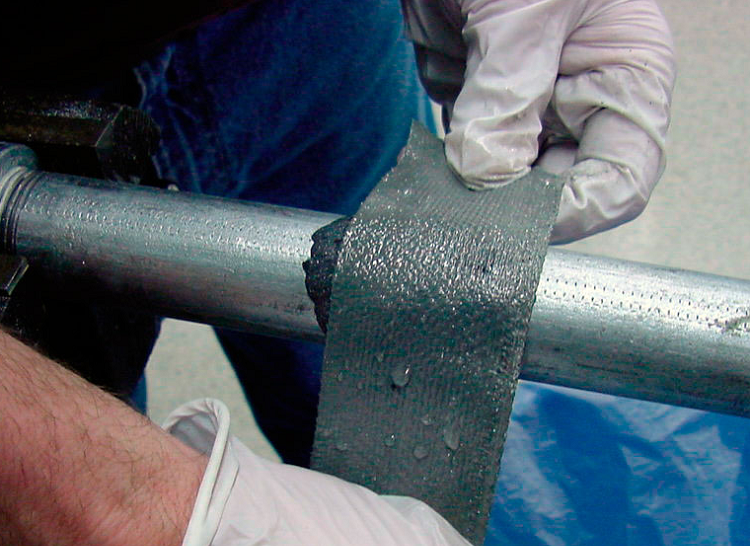

- As a rule, a fairly common problem associated with water supply systems is the failure of the drain. This is due to reduced pressure. Repair can be done in a fairly simple way: wrap the damaged area with gauze soaked in cement mortar.

Gauze soaked in cement mortar is recommended to wrap around the pipe in several layers. Not only the damaged point is wrapped, but also the areas that are located on each side of it. The total length of such a gypsum pad as a result should be at least 30 cm.

After the repair work, it will take 24 hours for the cement to harden. After that, you can turn on the water and continue to operate the repaired communications.

The main advantage of this method is the strength of the cement dressing. The disadvantages include the fact that in this way it is undesirable to repair the joints of pipes. Also, if the pipe is close to the wall, then to carry out such a repair event simply will not work.

- The second method includes an improved version of the first method. To repair the pipe in this case, you need a reinforced cement mortar. Asbestos fiber, which has high strength characteristics, acts as reinforcement. If desired, epoxy adhesive can be used instead of cement mortar.

The technology for repairing a damaged section of a water supply system in this case is no different from the first method. Water is also launched a day after the repair work.

- There is another way by which you can repair the water supply, however, it is relevant only if the hole in the pipe is small in size.

Helpful information! Another method that can help eliminate leaks is a rubber band. In this case, additional fixing in the form of a conventional wire will be required.

With a small hole, it is enough to screw a bolt, suitable in diameter, into the metal water pipe. Such repair refers to a temporary measure and is performed in such a way: the hole expands to the size of the bolt, and then screw the bolt and washer into it. The washer must be flexible in order to obtain the required tightness indicators.

A pipe from any material can be repaired simply by wrapping the leak with electrical tape, but this is a very short-term measure.

Repair of plastic water pipes

Plastic pipes for water not only easier to install, but repair of water pipes made of such material is easier to carry out than repair of a metal water supply pipeline. This applies even to cases where a major replacement of individual sections of the water supply is necessary. Consider the types of joints that are used in the installation of polymer parts:

- soldering method (thus, individual elements of the polypropylene pipeline are joined);

- threaded method (used when installing metal-plastic pipelines).

Soldering is quite simple, but the presence of welding equipment is a must. Even a novice who does not have any special building knowledge and skills can cope with the adhesion of plastic pipes.

Local repair of plastic or metal-plastic water pipes is carried out in three ways:

- In case of minor damage, repairs are carried out without the use of a special bandage. It is enough to take the most ordinary electrical tape and wind it around the damaged place. It is advisable to wrap the damaged area with several layers of electrical tape. After that, the pipeline element thus repaired will be able to last from several months to several years.

- In some cases, it is possible to repair a damaged section of a plastic water pipe by welding. As a result, the damaged area is sealed with its own plastic. To do this, it is necessary to heat the soldering iron and attach it to the damaged point - the plastic will melt and fill the damage. Such manipulation can be performed even with the help of a conventional lighter, however, such “artisanal” repairs should be carried out very carefully, since overheating of the pipe may occur.

- There is also a method that can be called insertion. This method is suitable for articulating pipes with different diameters. To do this, grease the outer surface of the pipe with a smaller diameter with glue and insert it into the pipe with a larger diameter. In the end, it is necessary to compress the junction with an iron bandage.

Important! In all cases where glue is used to eliminate the breakdown, experts recommend additionally insuring the repaired section of the pipe with a bandage.

There are a lot of ways to repair damaged sections of water pipes. From the simplest, “artisanal” methods, to the complete replacement of a certain section of the pipeline structure. The choice of method depends on the nature of the damage and, as a rule, on the particular case. If you wish, you can always turn to experienced professionals who can carry out quick and reliable repairs of any water supply networks.