Plumbing pipes are a large group of products that differ in production material, size, wall thickness. To ensure the proper operation of each sanitary function (supply of cold or hot water, sewage, etc.), a certain type of pipeline is required. You can make the right choice from the entire assortment of pipes for plumbing if you familiarize yourself with the technical characteristics and features of each item.

Content

Plumbing pipes for cold water supply

Cold water supply - essential communication in any apartment, private house, industrial and even warehouse. Cold water supply systems are mandatory even in areas that do not provide for the presence of a hot pipeline or heating.

Materials for laying a pipeline for supplying cold water can be as follows:

1. Galvanized steel. Zinc coating gives 100% corrosion protection to the pipe, but in places where galvanizing is damaged, rust will still form. Violation of the galvanized layer is inevitable in the weld areas, as well as on threaded joints.

Un galvanized (black) pipes cannot be used for water supply. Due to the constantly protruding condensate, the surface of the black steel product is quickly covered with rust. Corrosive accumulations lead to a violation of the integrity of the pipe.

To slow down the formation of rust, steel systems are coated with a coat of paint. This method makes it possible only briefly to avoid the occurrence of corrosion. Another significant drawback of non-galvanized steel will be overgrowing of the inner surface of the pipe, which over time greatly reduces its clearance.

2. Stainless steel. Stainless steel is more expensive than galvanized steel, installation is also complicated with it. Especially in cases where there is no thread on the measuring pipe segment. Of all the varieties of steel structures, stainless steel is considered the most durable and durable.

3. Copper. Noble metal, in properties significantly superior to steel. During its operation, there are no problems with corrosion, copper also has good bactericidal properties.

Helpful advice! Copper piping for cold water is recommended to be installed with a plastic coating. You will have to neglect the aesthetic qualities of the copper coating, but the condensate will not drain from the surface of copper and spoil linoleum or furniture.

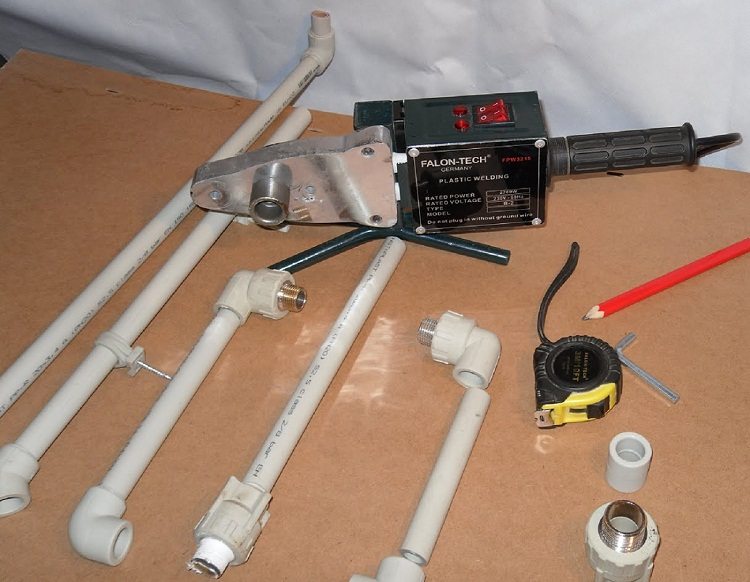

4. Polymer products. In the context of cold water supply, all plastic plumbing pipes, namely PVC (polyvinyl chloride), polypropylene and polyethylene (HDPE - low pressure polyethylene), will be completely equivalent in properties. The question of choice will be decided on the basis of the price and some nuances of the purpose of the pipeline.

In cold water systems, plastic pipes almost completely replaced metal counterparts. Cold water supply is the simplest communication with minimum requirements, so even relatively cheap plastic pipes able to ensure the effective operation of the pipeline.

Plastic and metal pipes for hot water and heating

The requirements for pipelines for these purposes will be completely different. Not all materials can withstand prolonged heating. On the other hand, in hot water supply and heating systems, plaque on the inner walls is less likely to occur.

Non-galvanized steel is better for hot water than for cold water: due to the lack of condensation, black steel does not rust. If we are talking about a heating system made of black steel, water must always be present in it. If you dump water from the system (with which oxygen will necessarily get into it), the steel will quickly become rusted.

Stainless and galvanized steel are free from the disadvantages of black, and show their positive qualities in pipelines with hot water.

There are practically no deficiencies in copper. The only factor hindering the widespread distribution of copper pipelines is too high a price. The installation of a pipeline for heating and hot water supply from copper involves the use of insulation, and this again entails additional costs. Insulation is necessary, since without it the heat loss will be great.

Plastic pipes are suitable for heating, but by no means all are only improved modifications of ordinary polymers. Simple polyethylene softens at +80 degrees, and cross-linked polyethylene withstands higher temperatures. The same with PVC: PVC without chlorine is suitable only for cold water, and chlorinated PVC is suitable for systems with operating temperatures up to +95 degrees.

Helpful advice! The best option among plastic products will be reinforced polypropylene. The reinforcing layer of aluminum foil and fiberglass prevents polypropylene from “creeping” under the influence of high temperatures.

Conclusion - plastic pipes are suitable for hot water and heating no worse than metal. True, the cost of reinforced polymers will not fundamentally differ from the price of analogues of metal. A significant advantage, which in any case will have plastic plumbing pipes, is ease, simplifying transportation and installation.

Another factor why plastic pipes are preferred in plumbing is ease of cleaning. From time to time, any sewage system will have to be cleaned, and deposits will accumulate on products of any material. But due to the smoothness of the walls of PVC pipelines, clogs will accumulate much more slowly, therefore plastic systems need less frequent cleaning.

Plumbing pipes for sewer

The requirements for the ability to withstand high pressure and temperature for sanitary sewer pipelines are low. The main aspect of this choice is the resistance of the material to aggressive substances.

1. Cast iron. Rarely used in other areas due to its fragility and heaviness, cast iron in sewers remains in demand. It compares favorably with steel with its inertness to corrosive chemicals (for this reason, steel is not considered at all in this category). Cast iron sewers are characterized by low conductivity of sounds due to the very thick walls. Cast iron is completely absorbed by all sounds, which is especially important for apartment buildings.

2. PVC sanitary pipe: it has occupied a special place among polymers due to its wide range of sizes, simple joining methods, smoothness of walls, neutrality to chemical reactions - all this meets the requirements for sewage.Simple PVC does not withstand temperatures above +60 degrees, but in most cases this limit fits into the framework of the working environment. If you think that this indicator is not enough, you can abandon PVC in favor of polypropylene.

The small wall thickness of plastic sanitary products (only 1-2 mm) is both a disadvantage and an advantage. Thin-walled pipelines are not good because their acoustic properties will be worse than that of thick-walled cast iron. The positive side is lightness.

3. Products from asbestos cement. They are also used for sewers. Asbestos cement is popular among large industrial effluents, and asbestos cement is not suitable for domestic sewers. Its installation is too time-consuming (joints are treated with cement mortar, in the worst case, with sulfur solution), asbestos-cement products themselves are very heavy and easily damaged when dropped or impacted.

When installing sewers, it is important to correctly calculate pipe slope. For different diameters, it will be different, the ratios are presented in table 1.

Table 1

| Diameter of sewer pipe (in mm) | Slope, in cm per 1 running meter |

| 40-50 | 3,5 |

| 100-110 | 2 |

| 110-150 | 1 |

| 200 and more | 0,8 |

Sizes of metal and plastic plumbing pipes

The optimal size choice will depend on the individual requirements for the pipeline, the working pressure in the system, the number of connected devices.

1. Cold water. When choosing pipes for cold water, it is worth considering the probability of overgrowing the system. The thinnest available will be copper pipes, which, with a diameter of 12 mm and with cleaning filters, can safely function in an apartment or private house. For steel pipes, the diameter should be larger, since overgrowing in this case is faster. Their minimum dimensions are 15-16 mm.

Plastic products are thicker, so their diameters start at 20 mm. At the same time, the internal clearance of PVC, polypropylene and polyethylene pipes will be the same as that of thin-walled metal products of the same diameter.

2. Hot water and heating. In hot water systems, pipe sizes will be similar to cold water pipelines. When installing a pipeline for heating, the pipe throughput must be increased, so the diameter for steel and copper will be 20 mm in diameter. PVC and polypropylene should be used starting from 25 mm.

Helpful advice! Too large sizes of heating pipes are also not welcome. The use of plumbing plastic and metal pipes with a diameter of more than 50 mm is possible only in large industrial areas.

3. Sewerage. The dimensions of the pipes in the design of the sewer system will depend on the features of the application. The calculation will be relevant for communications from any materials.

table 2

| Diameter of sewer pipe, in mm | Scope of application |

| 50-100 | Plumbing unit between 1-2 devices (excluding the toilet). Pipes of this diameter can be used when connecting showers, washbasins, sinks. |

| 110-150 | Plumbing unit with appliances working simultaneously and a toilet. This diameter is suitable for the riser of an apartment building. |

| 150-200 | Plumbing unit with appliances and several toilets. Well release formation |

| 200-300 | The connecting section between two wells (wells) |

There are also sewer pipes whose dimensions are less than 50 mm. PVC pipes, the sizes of which start with a diameter of 40 mm, are used only in simple kitchen sewers.

We hope that this review was able to provide readers with a complete picture of all types of existing plumbing pipes.When choosing pipes, it is worth focusing not only on the described properties of materials, but also on the specific requirements of the future system.