PE pipe is the common name for the corresponding product from a polymer material of low pressure. It is used in water supply systems with low pressure, sewer and drainage systems, where the special rigidity and strength inherent in metal structures are not required. And the weight and cost, in comparison with a similar metal product, for PE pipes is much lower.

Content

What determines the choice of HDPE as a material

The production of classic polyethylene is based on the method of polymerization of ethylene related to organic gases. Polymerization is a process of combining ethylene molecules into special chains, which takes place in a special pressure chamber at a temperature of one and a half hundred degrees and under a pressure of twenty atmospheres. As a result, a new material is formed with the characteristics that ensure the polyethylene pipe wide distribution:

- withstands pressure of three to five MPa;

- a cubic meter of PND weighs only 900 kg;

- exhibits slight expansion when heated. Thermal expansion will not exceed three percent of the overall parameters even if the design of the HDPE is heated to the maximum permissible temperature of seventy degrees;

- can be operated in a rather limited temperature range. If the temperature drops below zero, then the PND begins to glass. When the temperature reaches 40º C, the HDPE pipe loses ring stiffness.

The considered properties inherent in HDPE outline the boundaries of the possible use of a polyethylene pipe. It is used, as usual, for installation indoors or in trenches, where it is laid below the level of freezing of the soil.

PE pipe marking

PE pipes (HDPE pipes, PVP pipes, i.e., from high density polyethylene) are marked in accordance with GOST and ISO. The color of the marking strip of the pipe is of importance:

- yellow for gas pipelines;

- in blue for water conduits.

ISO requirements indicate the need for applying to each marked linear meter of pipe the method of embossing (not reducing the strength of the product) of the necessary information on the technical characteristics of the product:

- certificate of conformity;

- manufacturer;

- product standard;

- material used;

- outer diameter;

- minimum wall thickness;

- rated working pressure. Currently, this indicator distinguishes between the use of polyethylene as a starting material, which provides the pipe walls with resistance, indicated by indices 33 (still found, but rarely), 63, 80, 100, 100+;

- work environment;

- the most admissible pressure;

- batch number and release date.

The color of the pipe itself (gray, blue, black), as a rule, does not matter, although gray products are commonly used in sewer systems.

Parameters affecting product quality

Choosing PE pipes for operation in certain conditions, you should focus on some parameters:

- The source material from which the product was made. It is designed to operate at a certain pressure of the transported medium.PE 63, having a microporous structure, has the unpleasant property of sucking air into the system. This leads to vibration of the product and the occurrence of quite strong and unpleasant noises in the plumbing system. To avoid these effects, it is necessary to equip the pipeline design with cutoffs, air traps and other similar devices;

- Sizes and coefficient SDR. The outer diameter of PE pipes varies from ten to one thousand two hundred millimeters. The wall thickness is set by the manufacturer in accordance with the SDR coefficients that determine the acceptable ratio with the outer diameter. That is, a larger diameter value does not necessarily mean a greater wall thickness of the product. The higher the SDR value, the correspondingly lower the wall thickness and working pressure to which the product can be subjected. The increase in wall thickness affects the throughput, as it occurs due to a decrease in the internal section;

- The method of laying the pipeline. It plays a role if a closed gasket is used and safety boxes are not used. In this case, the indicator of the annular strength of the pipe becomes important, because it will experience not only the pressure of the working medium from the inside, but also the additional pressure of the soil from the outside. When the gasket is closed, it is necessary to select products with thicker walls so that they withstand additional soil pressure, and a larger diameter, in order to achieve high throughput.

Application of PE 80 and PE 100

The most popular varieties of polyethylene products are PE-80 and PE-100. The differences between them are expressed in:

- higher density and strength of PE-100, which has a more ordered structure of the crystal lattice. This circumstance also explains the receipt of a stronger and more uniform weld during welding;

- welding of PE-80 is carried out at a lower temperature;

- lower density of PE 80 caused an increased consumption of material for the manufacture of structures, their increased cost and transportation costs.

Application of products depending on SDR value:

- PE-80 SDR 21 - for pressureless or low pressure sewage and cold water supply;

- PE-80 SDR 17 - for supplying drinking water and water for household needs, for irrigation systems;

- PE-80 SDR 13.6 - for transporting cold drinking water;

- PE-100 SDR 26 - for transporting drinking and household water, liquid food products. Used for installation of water pipes in cities and outside cities;

- PE-100 SDR 21 - for the construction of water supply systems. Compatible with both plastic and steel structural elements;

- PE-100 SDR 17 - for the installation of gas pipelines and pressurized water supply, including using large diameter pipes;

- PE-100 SDR 11 - for high-pressure water supply systems and sewer collectors.

Disadvantages and advantages of using PE pipes

The disadvantages of products from HDPE stem from the properties inherent in the material. They can be reduced to several points:

- The presence of sufficiently stringent temperature restrictions narrows the scope, excluding, for example, use for the needs of hot water supply and heating systems;

- Susceptibility to the effects of sunlight (ultraviolet radiation) forces us to opt for materials that are more stable in terms of this indicator.

- Weak stability during ground movement with closed installation.

- The specificity of the installation work.

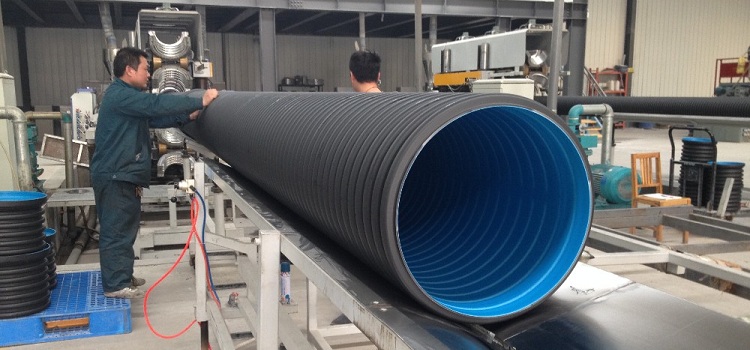

Installation of polyethylene pipes is a rather specific process for which special equipment is required

From the above it follows that we can talk not about the shortcomings, but about the properties that determined the scope of application.

The list of advantages inherent in PE products looks much more impressive:

- light weight simplifies transportation and installation process, accelerated even more when using compression fittings;

- ease of welding joints and their high reliability;

- lack of toxic compounds, environmental safety;

- resistant to corrosive chemicals;

- increased throughput, which does not decrease during operation, since scum or deposits do not adhere to smooth internal walls;

- low heat transfer practically does not lead to the formation of condensate on the outer surface;

- freezing of the working fluid will not cause a rupture of the pipe, which will respond by increasing the diameter, returning to the previous values during thawing;

- long term of use, equal to forty to fifty years;

- low cost.

Technical characteristics inherent in PE pipes have ensured their distribution. The use of new technologies allows you to get new advantages and the ability to use in new areas of human activity.