Hot-rolled steel seamless pipes are the most common format successfully used in all national economic sectors. These products are known for the greatest reliability, especially for laying communications for various purposes. Most often, a seamless hot-deformed steel pipe GOST 8732-78 is used in the construction of monolithic-frame structures, where reliability is above all under such impressive loads.

Content

- 1 General characteristics and basic information about solid pipes

- 2 What is important to know about the standardization of seamless products?

- 3 Areas of application of seamless hot-rolled products

- 4 Six classes of steel pipes and their use by industry

- 5 Pipe manufacturing process

- 6 Thick Wall Standards

- 7 Seamless products: weight and size

- 8 Tolerance Standards

General characteristics and basic information about solid pipes

Standardization hot rolling seamless tubes 8732 are produced from steel billets of the main grades:

- 10th, 20th, 35th and 45th standard;

- 35V;

- 40G and 45G;

- 15X and 40X;

- 9X1;

- 20PV;

- 30KhGSA;

- 17G1S,

- 09G2S;

- 10-20DDD.

Hot-deformed seamless pipes are available in the form of:

- thick-walled products;

- thin-walled products;

- standard products.

These products are in demand and universally produced by domestic and foreign enterprises. Hot-deformed pipes from steel billets are obtained during rolling of heated raw materials through specialized factory equipment. Under other conditions, it is impossible to comply with all the requirements of GOST.

The technology for the production of seamless pipes makes it possible to obtain especially thick-walled products

Good to know! The absence of a longitudinal welding joint is an important visual sign of the assortment of seamless steel pipes GOST 8732-78.

The guarantee of the reliability of the seamless pipe remains state standardization, which confirms control over the main quality indicators. These include:

- lack of flattening, sagging and bending inside the walls;

- high impact resistance of pipes.

At the manufacturing enterprises, metal quality control is periodically carried out, the chemical composition of the alloys used is confirmed. At the moment, seamless (b / w) pipe rolling is available in two ways:

- cold-deformed seamless pipes;

- hot-deformed seamless steel pipes GOST 8732-78.

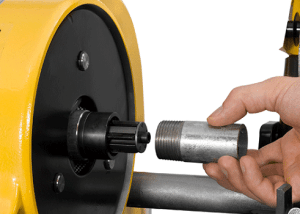

Considering the wishes of wholesale customers, chamfers and carvings are applied along the edged edges of the finished products. Also carry out the processing of slices - from one end or from two sides. It is worth clarifying with the managers of the enterprise all these terms of production before the formation of the order.

As a rule, from the warehouses of enterprises a batch of steel pipes GOST 8732-78 is shipped directly to the customer. Warehouses do not always have finished products in the required volume. The cost of pipes varies periodically, depending on the grades of steel, so all aspects are discussed in advance in the sales departments. The length of the product varies between 4.5m - 11.9m. It is recommended to check the available assortment with managers.

What is important to know about the standardization of seamless products?

Seamless pipe walls are produced in accordance with GOST only the specified thickness:

- 2.5, 2.8, 3, 3.5 mm;

- 4, 4.5, 5, 5.5 mm;

- 6, 7, 8, 9 mm;

- 10, 11, 12 mm;

- 14, 16, 17, 18 mm;

- 20, 22, 25, 28 mm;

- 30, 32, 36, 40, 45 mm;

- 50, 56 mm;

- 60, 63 mm

- 70, 75 mm.

All domestic enterprises that produce thick-walled and ordinary used pipes are guided by the requirement of several standards:

- GOST 8732-70;

- GOST 8731-74;

- GOST 9567-75;

- GOST 8732-78;

- TU 82-70.

The permissible length of hot-deformed pipes is invariably regulated by the state standard:

- measured and unmeasured length of products (allowed from 4m to 12.5m);

- multiple measured length of the products (allowed within the unmeasured length, plus an allowance for each slice of not more than 5 mm).

note! If you order a pipe length approximately, then the standards fluctuate in the format of non-dimensional length. The timing of the preparation of the required batch of seamless standard pipes varies from two to four weeks, but it all depends on the volume of the order. The minimum batch of hot-rolled steel pipes according to GOST 8732-78 should be about 3 tons.

The ratio of the wall thickness and the outer diameter of the hot-rolled pipe determines the face value:

- thin-walled b / w products;

- especially thin-walled;

- thick-walled b / w products;

- especially thick-walled.

The last two varieties are subjected to heat treatment, so that the products get additional resistance to pressure inside communications and trunk pipelines.

Seamless pipes are available in a certain diameter:

- 20, 21.3, 22, 25, 26.9 and 28 mm;

- 30, 31.8, 32, 33, 35 and 38 mm;

- 40, 42, 42.4, 44.5, 45 and 48, mm;

- 50, 51, 54 and 5mm;

- 60, 60.3, 63.5 and 68 mm;

- 70, 73 and 76 mm;

- 82.5, 83, 89 and 95 mm;

- 102, 104, 108 and 114 mm;

- 121, 127, 133, 140 and 146 mm;

- 152, 159, 165 and 168 mm;

- 178, 180 and 194 mm;

- 203, 219, 245, 273 and 299 mm;

- 324, 325, 351, 356 and 377 mm;

- 402, 406, 426, 450, 457, 465 and 480 mm;

- 500, 508 and 530 mm.

Reference! Revised domestic standardizations GOST R 53383-2009, GOST 8732 (78 and 70) offer a new level of quality for seamless products corresponding to products manufactured according to international standardization.

Today, the assortment of seamless products continues to be produced according to previously accepted GOST standards - 8732-78 and 8731-74. And in 2010, a national standard was adopted for products GOST R 53383-2009, regulated compliance with the requirements of TU 82-70.

According to GOST 8732-70, seamless steel pipes have an impressive weight, which is indicated in the standardization table. This is especially true for thick-walled products. Each heavy metal grade differs in chemical composition, plasticity of processing and degree of strength, as, for example, in seamless pipes of standard "70" or "78". To some extent, this affects the quality of thin-walled products, but a thick-walled solid pipe is guaranteed to be durable.

Areas of application of seamless hot-rolled products

The main feature of seamless steel pipes GOST 8732-78 and 70 is the absence of a welding joint, which is noticeable in welded products. This guarantees the greatest strength and sufficient resistance to external influences, as well as to the internal pressure of a liquid or gaseous medium.

The main advantage of seamless pipes of steel cold-deformed GOST 8732 (78) is a sufficient margin of safety along the entire length. Due to this, they are usually used in those conditions where other types of pipes do not confirm the standard of increased reliability. These products withstand impressive internal pressure, therefore, these products are contacted by enterprises:

- oil and gas industry;

- automotive industry;

- aviation;

- producing gas cylinders;

- heavy engineering;

- chemical industry;

- national economic profile;

- construction companies;

- engaged in laying communications.

Pipes are classified by the ratio of inner and outer diameter:

- small - within 114 mm;

- average diameter - in the range 114 - 480 mm;

- the maximum diameter is 480-2500 mm (as with a thick-walled steel pipe GOST 8732-78 or 70).

The widespread use of seamless products is due to their versatility and versatility. They are used:

- for trunk pipelines and communications in the private sector;

- for branches of small diameter when installing a water supply system, gas pipeline in country houses and country communities;

- in the production of steel structures of frame type in automobiles and mechanisms for various purposes;

- when producing fragments of metal structures, multi-span ceilings and covered galleries;

- to strengthen the strength of technical structures and hangars in industrial and agricultural production;

- for the installation of autobahns and bridges, tube-type lighting poles;

- for foundation piles in construction, etc.

Pipes produced by seamless technology, successfully perform the function of supporting and decorative structures in construction

Six classes of steel pipes and their use by industry

According to the requirements of GOST 8732-70 and 78, universal seamless steel pipes are made at specialized enterprises using the hot deformation method. They are produced from metal of a different brand, which is slightly different in chemical composition and other parameters. The main requirements are regulated by GOST 8731-74, 70, 78 and TU 82-70. For hot rolling, ingots of alloyed and carbon metal are used in accordance with GOST:

- 4543-71;

- 1050-88,

- 19281-89.

Whole products of measured and unmeasured lengths (up to 12.5 m) have a different assortment, including thick-walled ones, which is also limited by such parameters as the pipe wall thickness. This is the difference between the outer diameter and the inner hole, which regulates this parameter according to GOST 8732-78.

Seamless pipes of large diameter are able to withstand impressive loads, including use as:

- elements of hoisting mechanisms;

- piles for foundations for the construction of large floors in conditions of seismic activity;

- elements of heavy transport;

- multi-span beams;

- landslide structures and supports,

- solid structures in the construction of railway bridges;

- pipelines containing harmful reagents and explosive substances;

- hydraulic systems and steam pipelines with high internal pressure.

Based classification includes 6 classes:

1st grade - production of products from steel grades having a carbon composition, these are standard and “gas” products that are used in various conditions. It is not regulated by stringent requirements. These products are in demand in the construction of light supports and bridges, scaffolding and fences, irrigation structures and supports for laying cables. They are suitable for local branching of communications.

Pipes are divided into classes of strength, this determines their purpose and the possibility of application in a particular area

2nd class: these pipes are also produced from carbon steel grades. Demanded in pipelines and branching systems of highways for various purposes. If there are no special requirements, then they are suitable for high-pressure and moderate-pressure lines. This is the transportation of liquids and gaseous media, chemicals. Products are used in the manufacture of furniture on a metal frame and legs.

3rd grade: This type is well adapted to high internal pressure and piping performance in difficult climatic conditions. Such products have proven themselves in high-temperature production in boilers and furnaces, and they are also used in scientific tests, nuclear technology and oil pipelines.

4th grade: it is the main equipment for oil and gas fields, as well as steel pipes for the main pipelines leading from these fields. They are used when working with high pressure in exploration and in oil wells.

5th grade: these are products of increased strength, which are in demand in various fields. This is heavy engineering and installation of high structures in construction. This is the production of masts and frames of ships and lighthouses. This is the construction of cars, vehicles, cranes and cranes, as well as the installation of supports and towers of any functionality.

6th grade: products for supplying fluid to tanks under high pressure. Also, high-strength workpieces are used for pistons and piston pumps, and other areas, including mechanical engineering.

Seamless metal products are chosen for certain types of exploitation in industrial production. From distinguish and on another basis - thin-walled and thick-walled. Other quality indicators of thick-walled and thin-walled pipes, which have their own marking, are also taken into account:

- “A” - standardization of mechanical properties;

- “B” - standardization of the chemical composition of the metal;

- “B” - standardization, including control of the two above-mentioned indicators of steel quality;

- "G" - standardization of the mechanical properties and chemical composition of the metal, tested on analog samples;

- "D" - includes all the previous indicators, plus a hydraulic test for pressure resistance, which only thick-walled products can withstand.

Pipe manufacturing process

The modern technological process of hot-rolled pipe production is well established, which makes it possible to obtain durable and multifunctional products from metal billets. Accordingly, GOST 8732-78, products are manufactured from:

- open hearth bars;

- prepared pipe billets;

- forged blanks;

- continuously cast billets.

The production of hot rolled steel pipes GOST 8732-78 goes through several stages:

- the formation of a gap in the metal billet by means of a special piercing mill, which consists of a frame for piercing and conical shafts;

- heating of steel to 1200 ° C;

- bringing the product on special equipment to the expected format corresponding to GOST.

In accordance with GOST 8732-78 and 8732-70, hot-deformed seamless products are available with a wide range of assortment. Thick-walled products, with an outer diameter in the range of 25mm - 700mm and wall thickness in the range of 2.5mm - 75mm, are used for various technical and household needs.

The range of unmeasured length is limited to 4m - 12m, and the measured length assumes sizes up to 12m. Larger products are difficult to transport.

Attention! All questions on the standardization of GOST 8732-70 for seamless steel pipes and the choice of products for various purposes should be compared according to the tables. Clients usually receive all the advice and recommendations from the managers of the issuing company or through the information site.

Thick Wall Standards

GOST 8732 thick-walled seamless pipe is a high-strength product used for erecting all kinds of metal structures or transporting gases and liquid media under high pressure. Welded products are used less often, preference is given to seamless pipes, and steel of different grades is suitable for this.

To increase corrosion resistance, the inside and outside pipes are coated with a protective layer of zinc, chromium or nickel

So that the pipe does not rust inside (it is important for supplying a liquid of a certain chemical composition), thick-walled products are released from non-ferrous metals or nickel inside. They are used in the chemical industry and for transporting liquids from great depths.

Visually, this is almost always noticeable, but there are standards by which thick-walled products are manufactured - within 6mm - 12.5mm. If the hole inside is small and the wall is impressive, then these are especially thick-walled pipes. They are released only in a hot way.

Qualitative indicators of thick-walled pipes classify them according to the main standards: "B", "C", "D":

- “B” - standardization of the chemical composition of the metal, including GOST 19281-89, GOST 4543-71, GOST 1050-88 and 8732-70;

- “B” - rationing of thermal indicators;

- "D" - without special regulation, but with tests for internal pressure.

GOST 8732-70 also regulates the length of a thick-walled pipe - products of unmeasured and measured length:

- non-dimensional format from 1.5 m to 11.5 m;

- measuring format from 4.5m to 9m;

- length multiple of measured, within 1.5m - 9m (with 5mm allowance for each segment).

Thick-walled pipes do not bend well, but these are products of increased strength and resistance to mechanical stress. Their main function is the transportation under pressure of a gaseous and liquid medium. But they are also indispensable as frost-resistant building materials, and large-format welded products are also suitable for this. The requirements of GOST 8732-78 and TU 14-3-1128-2000 apply to these products. To produce blanks with thick walls, steel grades are usually used:

- 10G2;

- 09Г2С (low alloy alloy for welded structures, silicon and carbon up to 1% and 2% manganese).

On a note! Welding of pipes with a seam is carried out with or without preheating. The less carbon in the steel grade, the easier the welding. During welding, steel does not overheat, does not harden, and viscosity does not decrease. And the alloy’s resistance to low temperatures makes it possible to efficiently use 09G2S products even in the Far North.

At the request of the customer, steel pipes GOST 8732-78 and 8732-70 can undergo additional tests with hydraulic pressure in order to have confidence in their strength. The maximum pressure indicator is about 20MPa, which is allowed only in thick-walled products.

Finished products are tested not only for strength, but also for compliance with GOST standards for length, weight, wall thickness

Seamless products: weight and size

In accordance with the standards, the wall thickness determines not only the mass, but also the cost of an ordinary or thick-walled pipe. Metal, with a small margin of error, cannot be lighter or heavier. Therefore, by the weight of the pipe from the table, you can determine the length of the product and the wall thickness and vice versa.

Prices for hardware of any nominal value do not include the running meter of the pipe, but the amount of metal expended and the cost of processing. Of course, it would never occur to anyone to weigh each pipe. It is safe to say - if the same section and wall thickness of the pipe, then the mass of all of them will be the same.

Meter indicators vary slightly, which includes options:

- metal grade;

- pipe format;

- diameter (the difference between the cross section and wall thickness).

These parameters determine the so-called "theoretical" weight, noted in the normative tables of GOST 8732 for the assortment. The weight of the pipes is calculated:

- on a special "Metal Calculator" (this is a special computer program);

- a special formula available at each production site and at specialized companies involved in the supply of metal products.

The accuracy of the calculation implies the correspondence of the parameters that are entered into the program. The approximate mass of the ordered batch is determined by the theoretical formula, where the “theoretical” weight of the products (in linear meters) is multiplied by the length. This helps determine what transport capacity is required to transport a batch of workpieces for communications or construction.

Calculation of the weight of the pipes required for installation of the system allows you to determine the carrying capacity of equipment for their transportation

Formula 1 meter pipe:

0.02466 S (D - S),

where "D" is the outer diameter in mm, S is the wall thickness of the product in mm, and the metal density is adopted according to the standard of 7.850 g / cm³.

This standardization involves the production of pipes:

- dimensional format (within the unmeasured length of products);

- non-dimensional format (4m - 12.5m);

- multiple measured length (within the non-dimensional format with cutting tolerances);

- approximate length (within the unmeasured range).

Note! The company, at the request of the customer, is able to manufacture products with parameters that go beyond the limits indicated in the tables. For thick-walled products, the format should be specified, including the total mass of the batch. If it is an approximate length, then all other parameters must be agreed with the buyer.

Tolerance Standards

There is also a standard for limit tolerances for deviations in product dimensions, which range from:

- +10 mm (up to 6m long);

- +15 mm (over 6 m long, as well as with an external diameter of more than 152 mm);

- ± 500 mm (when the length of the products is considered approximate).

All deviations and tolerances are also governed by tables, including pipe spacing and ovality. The standard does not imply going beyond the specified deviations - pipe walls and diameter.

The curvature of any fragment of the product is also regulated by the standards:

- 1,5mm for thin-walled pipes up to 20mm;

- 2.0mm with wall thickness up to 30mm;

- 4.0mm - over 30mm.

The customer has the right to rely on what is compliant with GOST 8732-70 - seamless steel pipes are supplied strictly according to the correspondence between the wall and the inner diameter, which are specified in the batch. It is taken into account that deviations are possible both by difference and ovality, but to a small extent, and they are also determined by normative tables. The purchased pipe GOST 8732-78, at the request of the customer, can be galvanized.

When buying a batch of seamless steel pipes GOST 8732 78, the client has the right to demand all the marking information that is indicated in the technical passport or certificate of conformity. The necessary data include:

- product name;

- metal (steel grade);

- scope of application;

- product length and wall thickness;

- producer (country, enterprise);

- standard or regulatory document;

- permissible working medium for transportation inside pipes (steam, water, gas);

- articulation method (welding, docking);

note! About the purchase, it is worth inspecting the ends of the purchased pipes - they can undergo additional heat treatment or just be cut strictly at 90 °. The best option is when they are peeled or threaded (according to customer requirements), and not only have a bevel. For welding, a little metal is removed for beveling within 35 ° -40º, and there is an end ring no more than 1-3mm.

Quality welded pipes - products with parameters regulated by current standardization. All indicators are tested in production, including the maximum permissible internal long-standing, as well as resistance to external mechanical stress.