Welded straight-seam pipes are produced in huge volumes. They are in demand in the economic and communication sectors. Their difference from other types of tubular products is that at the final stage, as required by standards, an electric-welded steel pipe (GOST 10705-80) is connected along the seam using induction or arc welding. There are hot rolled and cold rolled varieties, and they differ in size and cross section. This determines the cost of the pipes, but does not affect the quality and performance.

Content

Scopes of welded pipes, classification and general characteristics

Pipes with a seam are produced according to different technologies, for example:

- longitudinally hot-rolled steel pipes, electric-welded (GOST 107 05-80);

- longitudinally cold-formed galvanized;

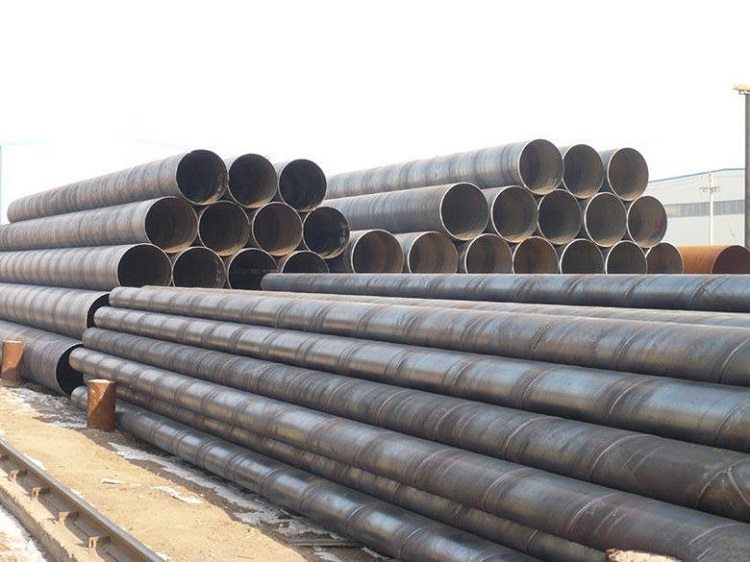

- spiral seam rolling.

Products are used in economic practice and in the form of blanks for other products and in finished form - for laying under such communications:

- domestic water supply and sewerage;

- trunk oil pipeline and gas pipeline;

- citywide and private heating systems.

Steel electric-welded pipes are used in construction - as a structural element or for reinforcing electrical networks.

Electric welded steel pipe also found wide application in other areas:

- metal structures for restoration of architectural objects;

- production of furniture on metal frames (sofas, bunk beds, tables and stools on metal legs);

- car production;

- frameworks of industrial buildings and hangars;

- trunk pipelines (pumping gases and liquids), etc.

It is interesting! For transportation of a gaseous medium under high pressure, special heavy-duty alloy alloy pipes are used.

Thick-walled electric-welded metal base is an indispensable material for the construction of indoor steel structures for open space. Galvanized steel pipes protected from corrosion are also available in accordance with GOST 107 05-80. They make a strong and durable frame for:

- industrial workshops;

- hangars for equipment and raw materials;

- warehouses and other facilities for logistics.

Thick-walled pipes carry a heavy load, because they have improved characteristics and bearing capacity. They successfully compete with conventional rental in areas such as construction and utilities.

Nevertheless, laying hydraulic communications is the main field of application for galvanized steel pipes electrowelded (GOST 107 05-80). Most water supply and sewage systems are mounted using this type of product. However, at significant costs for laying communications, the total cost depends not so much on the metal products themselves, but on the payment for the work of specialists in their installation. The cost of galvanized material is higher than ordinary iron, but the service life of these pipes is almost unlimited.

Length and shape of electric welded products

Foreign and domestic metal-rolling enterprises fully provide consumers with all types of standard products, including such face value as straight-seam steel electric-welded pipe manufactured in accordance with GOST 107 05-80.The production of sheet metal for welded products of various diameters is carried out both according to generally accepted standards, and with the expansion of indicators to increase the length of the pipe.

Note! The generally accepted standards for straight-seam steel pipes (in particular, GOST 107 05-80) and other markings (76 or 91) allow the production of pipes of standard and non-standard lengths (the latter is agreed with the customer).

The price of galvanized steel pipes according to GOST 107 05-80 will directly depend on the main indicators:

- diameter (inner and outer);

- steel grade;

- length.

The cost of pipes affects their cross-section and shape. The main varieties of steel pipe shapes in accordance with GOST –107 05-80:

- circle;

- oval;

- square;

- rectangle.

Rounded pipes are cheaper than others, because they are the least expensive and technologically advanced. For the production of square or oval steel profiles, additional costs are required (pressing). However, the price difference is not so significant if we consider the entire range of steel pipes produced in accordance with GOST No. 10705-80. But keep in mind that in the production of electrowelded metal products, ferrous metal of a different brand is used:

- steel 08 (SP).

- steel 1;

- steel 2 (St2sp / ps);

- steel 3 (St3sp / ps);

- steel 10 (PS).

Attention! Modern products from electrically welded cold-rolled sheets and hot-dip galvanized billets are produced in the range of 4 m - 12 m. With a diameter of 10 to 530 millimeters, the GOST 10705-91 numbers are used. Pipes with a section from 478 mm to 1420 mm - in accordance with GOST 10706-76.

Standardization does not regulate optimal performance not to limit the range, but to simplify the installation and delivery process. Docking and dismantling of a standard pipe of steel electric welded GOST 107 05-80 is carried out by a welding machine.

The cheapest are considered welded pipes of circular cross section with a longitudinal seam (straight-seam)

Standardization, assortment and classification of welded pipes according to GOST 10705-80, put into production since January 1993.

According to the type of production, steel pipe products according to GOST 10705-80 and grade 76 are classified as spiral-seam and longitudinal-seam.

Electric-welded products are produced from low-alloy steel (grades 09g2s, 17gs) and from carbon steel grades St3, St10, St20. This standard corresponds to products in accordance with GOST 76 and 80 with the marking:

- 1050;

- 9045;

- 380;

- 19281.

Products are formed from sheets of strip that must meet the standards of GOST 107 04-91, 107 06-76, as well as the equally common straight-seam steel pipes (GOST 10705-80). A uniform connecting seam along the entire length is performed by electric welding. Use induction (HF) or electric arc (TIG) welding. HF welding is less expensive in time and energy, which slightly reduces the cost of products. However, it is believed that the strength of the seam will be higher during electric arc welding. In any case, the seam of each pipe is controlled by a flaw detector.

Flat-rolled steel for pipes is regulated by GOST 10705-80 (products for large diameter water supply). The range of steel pipes is regulated by GOST 10704-91; General communications and other products are regulated by GOST 10706-76. GOST for steel pipes No. 107 05 standardizes the dimensions of rolled products by wall thickness (up to 2520 mm), with a standard length of pipes with a spiral seam within 10-12 m. GOST 10705-80 determines the range of electric-welded steel pipes, it is systematized and works from 01.01. 93 g

Regardless of the type of pipe, all its welded joints are checked for defects by a special device - a flaw detector

The most demanded products are in accordance with GOST 10705-80 and GOST 10704-76 (steel electric-welded straight-seam steel pipes of standard length), but blanks of unmeasured length are also regulated:

- diameter up to 30 mm - from 2 m;

- up to 70 mm - from 3 m;

- 70-152 mm - from 4 m;

- more than 152 mm - from 5 m.

- more than 152 mm, at the request of the customer, at least 10 m are produced;

- pipes up to 70 mm of different standardization - from 4 m.

Products of measured length:

- with a diameter of up to 70 mm - within 5-9 meters;

- 70-219 mm - 6-9 meters;

- 219-426 mm - within 10-12 meters.

Note! Welded straight-seam products with a diameter of more than 426 mm are unmeasured length. On request, pipes of different standards (80, 76) with diameters in the range of 70-219 mm are manufactured from 6 m to 12 m. And allowance for sections is allowed up to 5 mm - at any multiplicity.

Cold-rolled and hot-rolled products of unmeasured length are produced with different parameters:

- diameter less than 30 mm - from 2 m;

- section 30-70 mm - from 3 m;

- 70-152 mm - from 4 m;

- over 152 mm - from 5 m.

- thicker than 152 mm - from 10 m (on order);

- all groups of pipes on request up to 70 mm - at least 4 m long.

Billets with a thickness of 426 mm are produced to order of unmeasured length, and as agreed with the customer: with a diameter of 70 to 219 mm - within 6-12 meters.

Note! Due to the strengthening of the seam of the wide pipes, their mass increases, but within a few percent.

There are also 2 classes of accuracy in length - round steel pipes GOST 10705-80 are available:

- marking I - with deburring at the trimmed ends;

- marking II - without machining with machine cutting.

Standard deviation limits are also regulated, they should not exceed the permissible deviations:

- plus 15 mm - with marking I;

- plus 100 mm - with marking II.

By agreement with the customer, steel pipes GOST 10705-80 can be shortened from one or both sides, if this was not provided for by marking II.

Deviations in terms of the external cross section, ovality and uniformity of pipe walls allow deviations within ± 10% (for an average diameter, up to 152 mm), other standards are also regulated by GOST tables. The ovality of the pipe end does not exceed 2%.

Pipes according to GOST 10706 (and markings 76 and 91) allow curvature within 0.2% of the total length. Deviations in the curvature of the pipes in accordance with GOST 10705 - per 1 linear meter should not exceed 1.5 mm.

Attention! Electric steel welded pipe according to GOST 10705-80 in the marking after heat treatment is indexed by “T” after the word “pipe”, and by local processing of the weld after the flaw detector - “L”.

The amended version of GOST also stipulates some other deviations indicated in the corresponding tables used by manufacturers. To date, the assortment of steel pipes GOST 10705-80 is classified only according to the tables of measured and unmeasured lengths.