Despite the appearance on the construction market of plastic pipes, the products of cast iron pipe are still in demand. The use of special additives takes the strength of such products to a new level. GOST 9583 75 cast-iron water pipes create water pipelines that can be laid underground. However, in domestic water supply systems they can be met extremely rarely due to the low aesthetics.

Content

Cast iron pipe assortment

In accordance with GOST 9583 75, depending on the wall thickness, cast-iron pipes are divided into the following 3 groups:

- "AND". 7.4 ≤Sst ≤ 28.4 mm.

- "LA". 6.7 ≤Sst≤ 22.5 mm.

- "B". 8 ≤Sst≤ 28 mm, where S - wall thickness.

Parameters of pressure head cast-iron pipes of group “A” with a socket connection of GOST 9583 75 type are shown in table No. 1.

Table 1

| Outer diameter millimeters | Conditional pass, millimeters | Wall thickness, millimeters | Meters per ton | Weight 1 meter, kilograms |

| 1048 | 1000 | 24,8 | 1,73 | 572 |

| 945 | 900 | 22,3 | 2,08 | 480,9 |

| 842 | 800 | 21,1 | 2,53 | 394,6 |

| 738 | 700 | 19,3 | 3,16 | 316 |

| 635 | 600 | 17,4 | 4,08 | 244,8 |

| 532 | 500 | 15,6 | 5.45 | 183,5 |

| 429 | 400 | 13,8 | 7,66 | 130,5 |

| 378 | 350 | 12,8 | 9,39 | 106,5 |

| 326 | 300 | 11,9 | 11,74 | 85,2 |

| 274 | 250 | 11,0 | 15,7 | 65,9 |

| 222 | 200 | 10,1 | 20,49 | 48,8 |

| 170 | 150 | 9,2 | 29,67 | 33,7 |

| 144 | 125 | 8,7 | 37,31 | 26,8 |

| 118 | 100 | 8,3 | 48,08 | 20,8 |

| 98 | 80 | 7,9 | 61,73 | 16,2 |

| 81 | 65 | 7,4 | 80,65 | 12,4 |

Parameters of pressure head cast-iron pipes of the LA group with a bell-type connection. GOST 9583 75 are shown in table No. 2.

table 2

| Outer diameter millimeters | Conditional pass, millimeters | Wall thickness, millimeters | Meters per ton | Weight 1 meter, kilograms |

| 1048 | 1000 | 22,5 | 1,9 | 525,6 |

| 945 | 900 | 20,6 | 2,28 | 437,8 |

| 842 | 800 | 19,2 | 2,78 | 359,9 |

| 738 | 700 | 17,5 | 3,48 | 287,2 |

| 635 | 600 | 15,8 | 4,49 | 222,9 |

| 532 | 500 | 14,2 | 5,97 | 167,5 |

| 429 | 400 | 12,5 | 8,44 | 118,5 |

| 378 | 350 | 11,7 | 10,25 | 97,6 |

| 326 | 300 | 10,8 | 12,89 | 77,6 |

| 274 | 250 | 10,0 | 16,64 | 60,1 |

| 222 | 200 | 9,2 | 22,42 | 44,6 |

| 170 | 150 | 8,3 | 32,79 | 30,5 |

| 144 | 125 | 7,9 | 40,82 | 24,5 |

| 118 | 100 | 7,5 | 52,91 | 18,9 |

| 98 | 80 | 7,2 | 67,11 | 14,9 |

| 81 | 65 | 6,7 | 88,5 | 11,3 |

Parameters of pressure head cast-iron pipes of group “B” with a bell-type connection GOST 9583 75 are summarized in table 3.

Table 3

| Outer diameter millimeters | Conditional pass, millimeters | Wall thickness, millimeters | Meters per ton | Weight 1 meter, kilograms |

| 1048 | 1000 | 27 | 1,59 | 627,9 |

| 945 | 900 | 25 | 1,91 | 523,9 |

| 842 | 800 | 23 | 2,33 | 429 |

| 738 | 700 | 21 | 2,92 | 342,9 |

| 635 | 600 | 19 | 3,75 | 266,6 |

| 532 | 500 | 17 | 5,02 | 199,4 |

| 429 | 400 | 15 | 7,07 | 141,4 |

| 378 | 350 | 14 | 8,61 | 116,1 |

| 326 | 300 | 13 | 10,79 | 92,7 |

| 274 | 250 | 12 | 13,97 | 71,6 |

| 222 | 200 | 11 | 18,9 | 52,9 |

| 170 | 150 | 10 | 27,47 | 36,4 |

| 144 | 125 | 9,5 | 34,36 | 29,1 |

| 118 | 100 | 9 | 44,84 | 22,3 |

| 98 | 80 | 8,6 | 57,14 | 17,5 |

| 81 | 65 | 8 | 75,19 | 13,3 |

The regulatory document stipulates that in pressure head water supply networks, only bell-shaped cast-iron pipes are permitted.

Manufacture of bell-shaped products

This ferrous metallurgy product is manufactured using two technologies.

For the production of pipes, casting technologies are used, which consist in pouring liquid iron into special forms

Centrifugal casting. Liquid cast iron poured into a rotating form under the action of centrifugal force spreads over the walls and crystallizes.

Good to know! The amount of metal to be poured directly affects the wall thickness, and the shape of the product takes on any complex shape.

The advantages of centrifugal casting of pig-iron pressure head bell-shaped pipes GOST 9583 75 include:

- high performance;

- improved characteristics of cast iron;

- saving of raw materials and energy;

- the possibility of complete automation and mechanization of the process;

- no need to organize additional platforms for molding. The same applies to equipment for drying molds: it is not needed.

The main disadvantages are as follows:

- to make the wall of the required thickness, cast iron should be strictly dosed;

- In the casting process, regulated by the requirements of GOST 9583 75, special expensive machines and pressurized molds of increased strength are used. The need for such equipment increases the cost of products;

- the finished product takes on exclusively the form of rotation.

Semi-continuous casting. This technology consists in the free pouring of molten iron into a mold. There it cools and hardens. The partially cooled pipe is slowly removed from the mold. After allowing the workpiece to cool completely, it is cut and thus obtained products of the required length. To cool the mold, running water is used. The extraction of the pipe is carried out on the equipment, which is a table, which gradually moves down.

The positive aspects of this technology include:

- metal saving;

- cost reduction for replacement equipment;

- exact geometric dimensions;

- the possibility of producing long pipes.

Of the negative points worth highlighting:

- complex pulling mechanism;

- the complexity of extracting the workpiece.

Types of cast iron

All pressure pipes made of cast iron are characterized by high strength and the ability to operate for a long time. To withstand high pressure allows plasticity of the material. The properties of raw materials, in fact, determine the operational potential of a pig-iron pressure head pipe GOST 9583 75.

Today, the following types of cast iron are used in metallurgy:

- White cast iron. It is not subjected to blackening (graphitization). Despite this, this metal is resistant to the negative effects of corrosion and wear. As a rule, it serves as a raw material for the production of materials of a different kind.

- Gray cast iron. It is characterized by a high molecular weight and greater strength due to the fact that its molecular structure contains lamellar graphite particles. However, fragility complicates the execution of installation work.

- Ductile iron. Contains flocculent graphite additives. Being one of the varieties of white cast iron, this material has ductility and high strength.

- Ductile iron. Such an abbreviation refers to ductile iron with spherical graphite. Due to the presence of particles of this additive in the metal molecules, the casting properties of pipes manufactured in accordance with the requirements of GOST 9583 75 are significantly improved. It is from VChShG that the most durable products of pressure-type cast iron pipe metal are produced.

To seal joints during installation, asbestos cement is used.

Important! In this case, it is necessary to ensure that the connections are flexible. If increased seismic activity is recorded in the region, the joints should be further strengthened with couplings and overlays and the joints should be sealed with rubber rings.

Benefits and Application

GOST 9583 75 cast iron pressure pipes are reliable and durable (service life is about 100 years). Their outer surface is covered with a layer of oil bitumen, and they easily adapt to any climatic conditions. Such products differ:

- corrosion resistance;

- bending strength;

- resistance to shock loads;

- high elasticity;

- resistance to cracking.

GOST 9583 75 states that sewage, heating, gas and water pipes of large diameters are designed to transport various liquids under pressure on the basis of cast-iron pressure pipes. Laying can be underground and ground, channelless and channel. In general, it is recommended to use these metal products where the presence of loads significantly exceeding household loads is assumed. In particular:

- in slaughterhouses and meat processing enterprises;

- in the food industry;

- in educational institutions, sanatoriums and hospitals;

- in places where large numbers of animals are kept, for example, on farms;

- at public catering enterprises;

- for the supply of gas and water to micro-districts and quarters of cities and towns;

- for arrangement of storm drains and main sewer pipelines;

- in fire fighting systems;

- in the laboratories.

Cast-iron bell pipes are used not only for the installation of internal communications, but also external, including underground

In addition, this type of pipe products is used as concrete-filled piles to strengthen the soil during the construction of buildings and the construction of structures in ports.

Quality requirements

The transition of the cylindrical surface into the socket may be performed with a slope or in the form of a ledge. The deviation of the dimensions of the pig-iron water pipes GOST 9583 75 from the nominal values may fluctuate within the following limits:

- wall thickness -1≤ Sst ≤ + 0.5mm;

- length of a measured pipe - plus / minus 20 mm;

- the size of the inner diameter in the bell is: (1.50 + 0.002 Dн) ≤ Dвн ≤ + (2.50 + 0.002 Dн), where Dн. - nominal diameter;

- outer diameter (more than 300 mm);

- external diameter (not exceeding 300 mm inclusive) - plus / minus (4.50 + 0.0015 Dn.).

The degree of ovality of the pig-iron water pipe GOST 9583 75 should not infer its dimensions beyond the maximum permissible values, and the actual mass of the product should not exceed the estimated weight by more than 5%. The pipes are subjected to hydraulic tests taking into account their nominal size and class. Testing pressure of cast iron pressure pipes GOST 9583 75 are presented in table No. 4.

Table 4

| Diameter, millimeters | Test pressure level, kg / cm2 | ||

| LA class | Class A | Class B | |

| Over 600 | 20 | 25 | 30 |

| 300-600 | 20 | 30 | 35 |

| 300 and less | 25 | 35 | 40 |

Note! The level of working pressure in water supply pipelines does not exceed, as a rule, 3 ... 4 atmospheres. It can rise to a value of 8 or even up to 10 kgf / cm2 (the same numbers in technical atmospheres) only after pumping an engineering system within a microdistrict or at home.

Pipes are prepared for shipment to the customer that have passed the quality check and meet the requirements of GOST

The end of the pipe opposite the bell must be cut perpendicular to the longitudinal axis. Permissible deviation - not more than 0.5 degrees. A layer of protective non-toxic material is applied to the outer and inner and surface. The coating must maintain the tightness of the joint, not soften and not peel off, even if the temperature of the liquid reaches + 60 ° C. However, the customer has the right to refuse to apply a protective layer to the ordered batch of pipes.

Methods of connecting pipes of pig-iron pressure head GOST 9583 75

Elements of high pressure pipelines made of pipes of this type are connected in the following ways;

- bell-shaped connection "Tython". This method involves installing a two-layer seal in the socket. Installation is carried out using a special device. A similar method is used to connect GOST 9583 75 cast iron water pressure head pipes in highways with internal pressure not exceeding 1.6 MPa (16.315 atmospheres);

- socket-lock fixed connection of BPC ("Tiroflex"). The scope is the installation of vertical pipelines and the laying of heating systems, water supply and the transportation of effluents on unstable soils and in the mountains. A sealing ring is placed in the socket, and the connection procedure is completed by installing stoppers in the recesses. This technical solution allows the pipeline to move without depressurization by an angle of about 1.5-5 degrees;

- flange connection. This method is used when arranging viewing channels and pumping stations, and also when it is necessary to build an elevated pipeline capable of transporting liquid under a pressure of about 2.5 MPa (24.675 atmospheres). A gasket clamped by two flanges ensures a tight seal. Fixation of flanges to pipes is carried out by welding. At the same time, the docking places are boiled both outside and inside;

- welded joint. A connection of this type is formed in heating systems and water supply systems with a working pressure not exceeding 1.6 MPa. On the territory of our country, welding of cast-iron pipe elements has not found wide application.The reason lies in the banal lack of competent specialists and in the shortage of electrodes with nickel and iron-nickel. In our country they are not produced.

The simplest is the socket connection of pipes, since it does not require the use of welding equipment

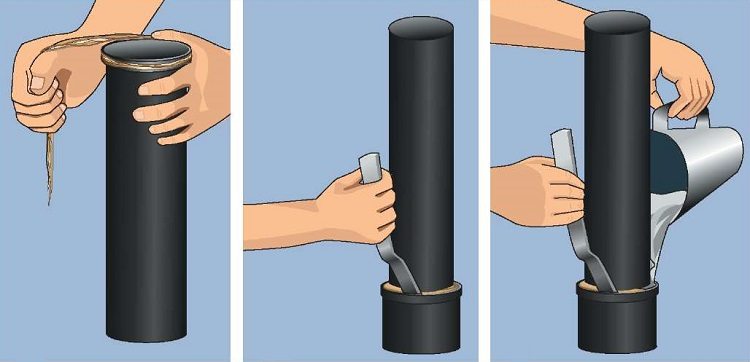

Cast Iron Pipeline Assembly

It is not difficult to mount a pipeline from such pipes, you only need to strictly adhere to the procedure:

- First, the end face of the next is inserted into the socket of the previous pipe. Moreover, the direction of the bell should be oriented against the flow of liquid;

- then the lower and upper pipes are fixed on the supporting surface;

- the next stage is the isolation of the joint between the smooth end of the upper pipe and the bell of the lower;

- Having completed the joint sealing procedure, fix the upper pipe as tightly as possible on the supporting surface. After that, you can proceed with the installation of the next segment, inserted into the socket of an already fixed pipe.

Important! At the same time, the lower part of the pipeline must be fixed tightly, and the upper - with a gap, which will allow the pipe to rotate.

The connection of the line element with the shaped part is carried out similarly: that is, at first the smooth end of the pipe is inserted into the bell of the shaped. And then - the same sequence of actions adjusted for smaller dimensions of the shaped part. The quality of the connection is largely determined by the correctness of the procedure for minting the joint. Therefore, we dwell on this issue in more detail.

Bell end

High-quality and proper connection of pipes is a rather important point. First of all, this concerns the reliable sealing of the bell.

To make the pipe joint tight, it is necessary to patch it with plumbing flax, and then pour it with cement mortar

To perform this operation, a high-quality hemp fiber is used. It should not contain wood or any impurities, otherwise complete sealing will not be provided, and pipes at the joints will leak. If a mixture of asbestos cement is used for sealing, a pre-tarred hemp strand coiled into a bundle is introduced into the socket first. The thickness of the bundle should not be much larger than the bell-shaped gap.

The harness in the gap of the bell is caulked (compacted) with a hammer and a caulk. At the same time, it is necessary to control that the strand is 30 mm from the end of the bell. The ingredients are included in the mixture of asbestos cement in the following proportions: Portland cement grade 400 (higher and higher) - 70%, asbestos fiber (grade 4 and higher) - 30% of the total mass. Before use (30-40 minutes), the mixture is moistened by adding water. Of the total weight of the dry mixture, it should be 10-12%.

Another way to seal the bell is to use waterproof, expandable cement. This is a more advanced method of assembling cast iron structures. This material is characterized by water resistance, as well as the ability to expand and self-seal during solidification. Due to the absence of the need to mint and caulk joints, the procedure for sealing a bell takes a little time. The work is carried out in the following sequence:

- winding in front of a bell of white strands. It is necessary to observe the following requirements: pipe diameter of 50 mm - two screws of a strand with a thickness of 5 and a length of 440 millimeters are wound; the diameter of the pipes is 100 mm - the thickness is the same, and the length is 70 mm;

- draft thin caulking strands in the bell;

- centering the structure with three metal wedges.

- Cementing: pipe diameter 50 mm: cement volume - 100 g .; pipe diameter 100 mm: cement quantity - 200 g. In both cases, water must be added up to 70 percent of the cement volume.

Important! To create a uniform gap on all sides, the wedges must be driven between the socket and the pipe with light hammer blows.

For branching the pipe, tees are used, which are also connected to the pipes using the "socket" method

Often there is a need to change the direction of cast-iron pipelines, install various fittings and create branches. For this, shaped parts are used: couplings, outlets (used to empty pipes), flanged and bell-shaped nozzles, crosses and tees, elbows and elbows. When arranging a water supply network based on pig-iron pressure-end bell pipes GOST 9583 75, the use of connecting parts made by welding from sheet steel, as well as other similar products, is allowed.

Connection of cast iron pipes with plastic

It should be noted that the connection created using special fittings in this case does not differ in durability. The reason is that at high temperature the plastic expands less than cast iron. As a result, the connection will turn out to be uneven, which can cause the fitting to fail. Therefore, the installation is carried out using the socket at the ends of the pipes. This work does not require welding. The tightness of the structure is ensured by a dense rubber ring serving as a sealant, which is installed in the socket. Fastening pipes to the wall is carried out using clamps. It would seem that everything is very simple. However, one should not forget about some of the nuances. So, for example, when working with a pig-iron pressure pipe GOST 9583 75, the use of a hammer with a metal tip is not allowed. This is due to the fact that part of the material can simply break off and, once inside the trunk, clog it. It is recommended to use a hammer with a rubber or wooden nozzle.

In conclusion, it should be said that the appearance of plastic pipes for water supply did not reduce the relevance of cast-iron pipes. They are widely used at present.