Pipes for water supply are used for laying various water utilities of various configurations. Water pipelines can deliver to consumers with different water temperatures (hot or cold), which affects the choice of material for the system. Today, the range of such elements of water supply communications is incredibly wide, so for the right choice you need to get acquainted with all types of water pipes.

There are many types of pipes used for water supply of residential, household and industrial facilities

Content

Selection based on operating conditions

Communication, which is mounted indoors, is also called wiring. The main task of water pipes is to deliver water to plumbing fixtures and other equipment. The correct selection of materials depends on the operating conditions and features of a particular communication.

Note! Products made from various modern polymeric materials, namely polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), polybutylene (PB) and metal polymers, as a rule, have operational limitations. These restrictions depend on the specific conditions of use.

In turn, some metal elements of pipeline structures can be used with almost no restrictions. These products include: galvanized steel, stainless steel, copper, bronze and brass. Water pipelines made of these materials can be used to transport hot and cold water under high pressure. In addition, such materials are excellent for organizing communications in various enterprises where industrial water is required.

Plastic products can be mounted in special channels or under skirting boards. This will not only improve the appearance of the room, but also protect the communication from mechanical damage, which is very important, since the strength of such pipes is quite low. There are also special flexible pipes called eyeliners. Such hoses can be installed openly in safe places (for example, behind the toilet bowl).

Each type of these products has limitations on the pressure that they can withstand. The selection of parts for a particular system is carried out taking into account the pressure in it. In this case, it is recommended to select pipes with a maximum pressure value that exceeds the maximum pressure in the system.

Consider a few more tips for choosing a pipeline for transporting water, depending on operational features:

- in houses where there is a centralized water supply, pressure indicators can vary from 2.5–7.5 bar. In this case, the peak value can reach 10 bar, and if the communication is checked, it can reach 12 bar. In this regard, it is recommended when choosing pipes for water to provide a certain margin of safety;

- the main factor to be guided by when choosing water supply elements for open (above ground) installation on the street is the coefficient of ring stiffness;

- in the event that the polymer pipeline is laid in the soil, without using a protective channel, it is advisable to choose products equipped with a special protective coating.

How to determine the required pipe size?

In order to calculate the necessary indicators of the cross section of the pipeline and fittings to it, the value of the internal diameter (DN) or, as it is also called, a conditional passage is used. The most common sizes of the internal indicator of the cross section of water pipes are:

- 15 mm;

- 20 mm;

- 32 mm.

Pipes are available in different diameters, for household purposes usually choose products ranging in size from 15 to 32 mm

Product length is also important. This indicator for water pipes can vary depending on the material of the products. The size range is from 4 to 12 m. Plastic and metal-plastic products are stored, sold and transported in special coils (bays) or in the form of ordinary segments.

Advice! Experts recommend buying pipes for laying water pipes with a certain margin. As a rule, this stock is from 2 to 5% of the total length calculated by the project.

Consider the main factors on which the choice of the cross-sectional indicator of the future water supply depends:

- water pressure in the system. In this case, a certain pattern can be traced: the higher the water pressure, the smaller the diameter of the pipeline should be and vice versa. This is due to the fact that fine communication at low pressure produces a weak stream of water;

- length of communication. There is also a pattern here: the greater the length of the water supply system, the weaker the water pressure in it. Therefore, in such a situation, pipes of larger diameter will have to be used;

- the number of butt elements and turns in the system. Joints and turns in the water supply structure reduce the pressure in the system. To increase the pressure, pipes that have a larger diameter can be used.

For accurate calculations of the cross-sectional index, experts recommend using formulas that can be found on the Internet at one of the profile sites. In addition, it is recommended not to save on pipe diameters when the pressure in the system is too low for normal water delivery.

Pipes with high strength indicators are used for laying underground and working under high pressure water pipe sections.

As a rule, before entering the apartment, the general communication is laid out from elements that have cross-sectional indicators from 20 to 32 mm. And in turn, for intra-apartment wiring, products with an internal diameter of 15 to 20 mm are used.

Types of pipes for water supply and the features of their choice

How to choose pipes for water construction? When choosing pipes for water supply, many factors must be considered. Consider the main criteria that should be considered when choosing these products:

- material strength;

- cost;

- resistance to temperature changes (pipes for hot water and cold can be made of different materials);

- resistance to pressure;

- anticorrosive qualities;

- features of the installation of communications from one or another material;

- operational period.

Depending on the material of manufacture, water pipes are divided into:

- metal;

- metal-plastic;

- polymer.

In turn, metal pipelines can be made from the following metals:

- steel;

- copper.

And plastic products can be made of such materials:

- polypropylene (PP);

- polyethylene (PE);

- polyvinyl chloride (PVC).

Helpful information! Modern plastic products are characterized by low cost and excellent anti-corrosion properties, which largely determines their huge popularity among the population.

Any of the varieties of water pipes is distinguished by its advantages and disadvantages. In this regard, their choice is made individually depending on the specific case.

Steel pipes

Steel pipes for water supply are quite durable and, despite the emergence of modern plastic materials, are still used in laying various communications (including water). Steel pipes are made from two types of steel:

- black (high strength);

- galvanized.

Consider the main advantages of steel products that are used for laying water supply systems:

- high resistance to temperature extremes;

- galvanized hot or cold water supply piping is highly resistant to harmful corrosive effects;

- steel products are able to withstand high pressure, as they have high strength;

- quite a long service life, which with normal use of the pipeline can reach 50 years.

The biggest drawback of steel pipes is that over time their inner lumen narrows due to deposits on the walls

Like any other product, steel pipes have some disadvantages that need to be addressed. Consider the main disadvantages of such products:

- condensation can form on the surface of such a pipeline;

- rather complicated installation, which is associated with their high weight. When laying steel communications, special tools and building skills will be needed;

- over time, a narrowing of the internal lumen is observed in the steel pipeline. This is due to the fact that the inner walls of steel products are not smooth enough and salt deposits accumulate on them;

- in addition, the disadvantages of steel products include the high coefficient of thermal conductivity.

Advice! Experts recommend the use of steel products for the reconstruction of communications from a similar material. If it is planned to lay a new water supply structure, it is more advisable to choose parts from another material.

Copper pipes

Copper alloy products are quite ductile and have a high cost, in comparison with other analogues. Such pipes are conditionally classified as an elite variety. They can be used both for hot water supply (domestic hot water) and for cold water supply (cold water).

Consider the main advantages of copper pipelines:

- presentable appearance. The copper construction is pleasing to the eye and can become an adornment of almost any interior;

- resistance to high temperatures;

- environmental friendliness. Copper does not emit substances harmful to human health, even in the case of interaction with chlorine, which is contained in drinking water;

- long service life (up to 70 years or more).

The disadvantages of this product include:

- high price;

- small assortment in the market. In some cases, it is quite problematic to find pipes of the right sizes, as well as accessories for them;

- insufficient strength characteristics. Mechanical shocks can damage the copper pipe;

- quite complex installation, requiring special skills. Docking of copper communication elements among themselves is done by welding. In this case, as a rule, a special gas burner is used. Such work requires a gas burner and certain skills;

It is important to remember that for copper pipelines it is necessary to use connecting elements (fittings) of the same material, otherwise the interaction of copper with another material can lead to oxidation of the pipes. To avoid this, it is recommended that you buy only copper fittings. In addition, before installing copper communications, it is imperative to clean the system.

Plastic pipes

Plastic pipes are considered an excellent option for organizing water supply in the country. However, for an apartment or a private house it is still better to choose another option. Pipes for heating and water supply made of metal-plastic have a structure resembling a sandwich, which consists of three main layers. Consider them:

- Internal polymer.

- Medium metal. As a rule, it is represented by an aluminum layer, which can be of three types: solid, spiral, perforated.

- Outside polymer.

Such pipes have the following advantages:

- light weight;

- good strength characteristics due to the metal layer;

- quite simple installation;

- good coefficient of plasticity, allowing bending metal-plastic products. Flexible pipes are easier to install, since the bending of the communication section avoids the installation of a connecting fitting;

- good temperature stability. Metal-plastic water supply can withstand temperatures that reach +75 ° C;

- such products can be used for underground laying;

- democratic value;

- long service life (under normal use reaches 35 years).

Note! Metal-plastic communications from time to time need to tighten threaded joints.

Among the minuses of metal-plastic parts, the following can be distinguished:

- poor resistance to low temperatures;

- the cost of connecting elements for such structures is quite high;

- connecting nodes in a metal-plastic construction are characterized by low strength.

Plastic pipes

Today, polymer pipelines are considered the most popular, as they have many advantages, at a fairly low price. Plastic pipe products are used both for installation of internal water distribution, and external.

Polymer pipes in many qualities are not inferior to metal and when laid in the ground they do not corrode

Consider the main advantages of polymer water supply networks:

- low cost;

- high resistance to harmful corrosive effects;

- presentable appearance;

- smooth inner walls, on which salt deposits are practically not delayed;

- ease of installation;

- long operational period;

The most popular types of polymer pipes are:

Polypropylene (PP). Such products have the most extensive operational area. According to their characteristics, PP pipes resemble cross-linked polyethylene parts, however, they have a lower cost. Polypropylene hot water pipes can withstand temperatures of 95 ° C. In addition, polypropylene is a fairly durable material. Installation of communications from the software is carried out through two main methods:

- coupling soldering;

- butt soldering.

Flexible pipes for water supply are produced from polypropylene, which have the same resistance to high temperature as rigid smooth pipes. Flexible pipe for water from PP does not emit substances harmful to human health and is able to withstand pressure up to 10 atmospheres.

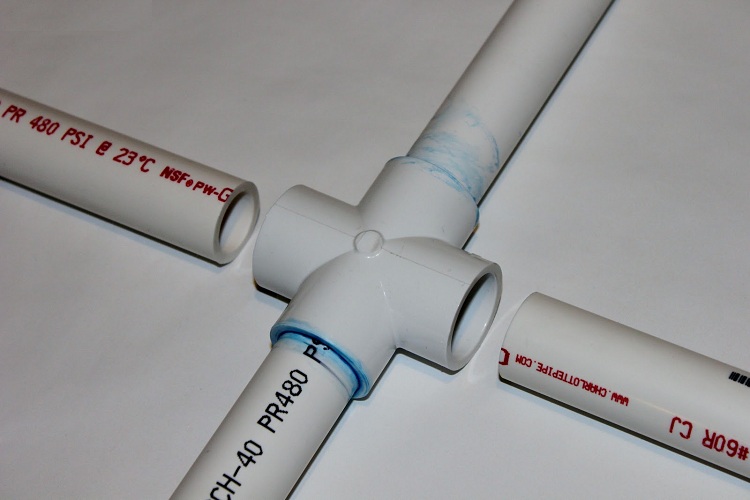

Polymer pipes are connected with the same fittings that are fastened with thread, welding or even glue

The main disadvantage of polypropylene products is the inseparable design.When dismantling a polypropylene water system, you will have to resort to pipe cutting.

Polyethylene (PE). Among the main characteristics of PE pipes, elasticity and good strength can be noted. Polyethylene products do not burst when freezing water in them. Such pipes for hot water supply are not suitable. Another quality of communications from this material is considered to be low thermal conductivity.

The temperature that PE pipelines can withstand does not exceed +40 ° C; therefore, such pipes are suitable for cold water supply. There are products made of special cross-linked polyethylene, which is more resistant to high temperatures and is suitable for the installation of hot water systems.

Polyvinyl Chloride (PVC). PVC parts are characterized by low cost and versatility. Polyvinyl chloride pipelines are used in the installation of hot and cold water systems and heating communications. Installation of such pipes is carried out by the following methods:

- using fittings;

- using special glue.

Flexible pipes are also made from polyvinyl chloride, which, like polypropylene, have high temperature stability and are used mainly for laying water pipes transporting hot water.

When choosing pipes for a water supply system, you need to remember that first of all it is necessary to find out the pressure that is inherent in your water main. In addition, it is recommended to choose products that are resistant to corrosion. Installation of the water supply system can be carried out both independently and use the services of a specialist who will carry out a quality installation of the system.