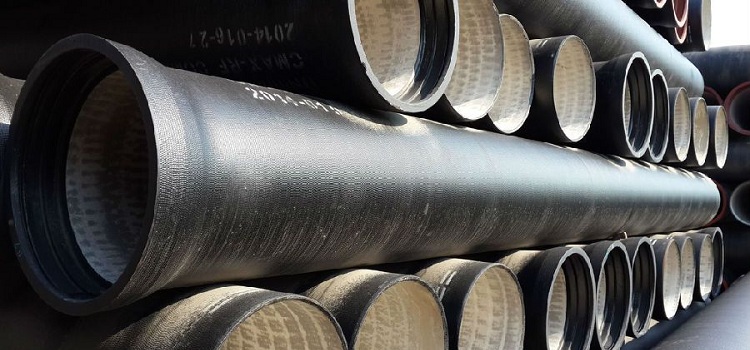

There are a large number of types of pipe products made from plastic on the construction market. But they are not always able to completely displace familiar materials. This concerns the installation of sewage systems, where cast-iron pipes remain very popular today. This material is inherent in a lot of advantages that ensure the smooth operation of the sewage system. At the same time, the life of cast-iron pipes is measured in tens of years.

Cast iron pipes have a large weight, so the calculation of this parameter is necessary in many cases

Content

Benefits

Despite the rather large weight of cast-iron pipes, it has historically happened that they are mainly used in sewage and water supply systems. Today, along with improving the quality of the source material itself, there is an improvement in the installation methods of cast-iron pipelines. The introduction of spheroidal cast iron, resistant to cracking and more ductile, gave the pipe products made from it a second life. And thanks to the different diameters of cast-iron sewer pipes, these products began to be used on a par with polymer pipes - the undisputed leaders in the plumbing market.

The advantages of products made of ductile iron (this abbreviation stands for High Strength Cast Iron with Spherical Graphite) experts include:

- low accident rate due to high strength;

- the service life reaches 100 years or more;

- corrosion resistance;

- withstands frosts down to -60ً С;

- ease of use of proven thermal insulation technologies;

- good resistance to external loads;

- It is allowed to lay a ductile iron sewer pipe at a depth of 8 ... 10 meters;

- the possibility of recycling cast iron products after their useful life.

Why you need to determine the weight of the pipeline

The weight of 1 meter of cast iron pipe products must be known when it is planned to carry out bulk purchases. Then the pipes are sold in tons. At the same time, the mass of one product does not matter, since the meter is calculated on the contrary, based on data on the number of meters per ton. For retail purchases, the weight of the pipe is not taken into account. Of key importance in this case are the dimensions of cast iron pipes. It is also necessary to search for the weight of products in order to:

- determine the carrying capacity of the vehicle for transportation;

- find out the cost of transportation;

- calculate labor costs for each shift;

- determine the capacity of the crane or loader.

Important! Incorrect calculations can lead to accidents during the transportation of cast-iron pipe products or during work with them. For example, the beams will curve, the pendants will break, the crane slings will break.

Without preliminary calculations, one cannot be sure of 100% success of the work.

Operational standards

On the territory of our country there are a number of GOSTs, to which pipes must meet the criterion of "destination". For example, products made of gray cast iron, the inner diameter of which varies in the range 65≤ D ≤1000 mm, meet the requirements of State Standard 6942 98.Products of this type are used to equip drainage systems in modern multi-storey buildings, since the diameter of a cast-iron household sewer pipe is usually within this range.

The quality of the ductile iron pipes is determined by the following regulatory documents: SP 40-106-202 and TU 14-161-183-2000. Using these products, long pipelines are laid. And they are great for arranging delivery systems for drinking and industrial water, storm drains, oil and gas pipelines.

There is another approach to the classification of cast iron pipe products - by wall thickness. In particular, GOST 9583-75 indicates that high-strength products are of classes A, LA and B. And the same regulatory document contains uniform requirements for the value of the outer diameter of cast-iron sewer pipes. This indicator varies in the following ranges: 81≤ Dн. ≤ 1048 mm.

Below is information on the range of changes in weight characteristics and other sizes of cast-iron sewer pipes of class A.

Meters per ton –1.73 ≤ L ≤ 80.65;

- weight 1 lm (hereinafter referred to as “running meter”) - 12.4 ... 578 kg;

- wall thickness, mm - from 7.4 to 24.8;

- nominal pass, mm - 65 ... 1000.

For products of class LA, these data look like this:

- meters per ton –1.9≤ L ≤ 88.5;

- weight of 1 lm, kg - 11.3 ... 525.6;

- wall thickness, mm - from 6.7 to 22.5;

- nominal pass, mm - 65 ... 1000.

As for Class B pipe products, they have:

- meters per ton –1.59≤ L ≤ 75.19;

- weight of 1 lm, kg - 13.3 ... 627.9;

- wall thickness, mm - from 8.0 to 27.0;

- nominal pass, mm - 65 ... 1000.

What parameters affect the weight of the cast iron pipe

An analysis of the above data indicates the dependence of the weight of cast-iron sewer pipes on the wall thickness, all other things being equal. The higher this indicator, the, respectively, the mass is greater. Other factors practically do not affect the weight of 1 lm in any way. product data. For example, if the conditional passage of pipes of all classes is the same, all the same, the weight of a Type B pipe will be greater than that of other varieties of this product.

Good to know! An important role is also played by the type of compounds. With the same diameters and sizes of cast-iron sewer pipes, the mass of products with a bell will differ from the value of this parameter of exactly the same pipes with a thread.

Of course, the differences in weight of two individual units of pipe products differ slightly. However, if you purchase them in bulk, the difference in mass will significantly increase or, conversely, reduce financial costs.

How is the weight of cast iron pipes calculated

From the geometry course of a secondary school, it is known that in order to calculate the mass of a cylinder (read pipe), it is necessary to know its outer and inner diameters, height (in our case, pipe length) and specific gravity of the material (we have cast iron). If one of the diameters - external or internal - is not indicated in the passport for the tubular product, it can be found by adding / subtracting to / from the known parameter (s) twice the wall thickness.

The sequence of arithmetic operations looks like this:

V total = π × Don × H

V total - total cylinder volume; π is a known constant; D - outside diameter; H is the height;

V ext. = π × D int. × H

V ext. - the volume of the inner cavity of the cylinder; Ext. - the inner diameter of the cylinder.

Vst. = Vtotal-Vtv.

Vst. Is the volume of the cylinder wall.

P = ρ × Vst.

P is the weight of the cylinder; ρ is the specific gravity of the material.

As an example, we calculate how much the gray iron sewage pipeline weighs 200 meters, an outer diameter of 110 mm and a wall thickness of 7.4 mm.

Vtotal = 3.14 × 0.11 × 200 = 69.08 m3;

D ext. = 0.11 - 2 × 0.0074 = 0.0952 m;

Vvn. = 3.14 × 0.0952 × 200 = 59.7856 m3;

Vst. = 69.08 - 59.7856 = 9.2944 m3;

The specific gravity of gray cast iron is as follows: ρ = 7100 kg / m3. Substitute this number in the final formula.

P = 7100 × 9.2944 = 65990.24 kg.

That is, a gray cast iron sewer line 200 meters long weighs almost 66 tons!

A two-hundred-meter-long section of a pig-iron pipeline will have a solid weight of more than 60 tons

It should be remembered that if the diameters and wall thicknesses of cast iron pipes are the same, their mass does not necessarily coincide. Various factors influence the value of this parameter: set of parts, type of connection, type of cast iron, and storage conditions. Even atmospheric precipitation increases weight. So, for example, a cast-iron pipe with a diameter of 150 mm, which has repeatedly been in the rain, will increase by 5 percent. Therefore, the weight of the tubular product obtained in the calculations differs from the actual one.

On the Internet, you can find many options for an online pipe weight calculator, including cast iron.

On a note! Working with most of these services is not difficult, and anyone who has only general ideas about computer technology can use them.

The sequence of actions looks like this:

- go to the main page of such a web resource;

- choose metal type - cast iron from the drop-down window of the calculator;

- choose from the proposed assortment "Round pipe";

- indicate the grade of cast iron, for example, with spherical graphite VCh60;

- we enter the parameters of a round cast-iron pipe: length, wall thickness and its outer diameter;

- click the button “Calculate”.

As a result, the rolled metal pipe calculator will give you the exact weight of the cast iron pipe in kilograms.

In general, we can say that if it is not intended to operate pipes under high pressure (which is typical for sewage systems), it makes no sense to choose these products with a wall of large thickness. This will increase the total weight of the purchased batch of cast iron pipes, which will lead to transportation difficulties.