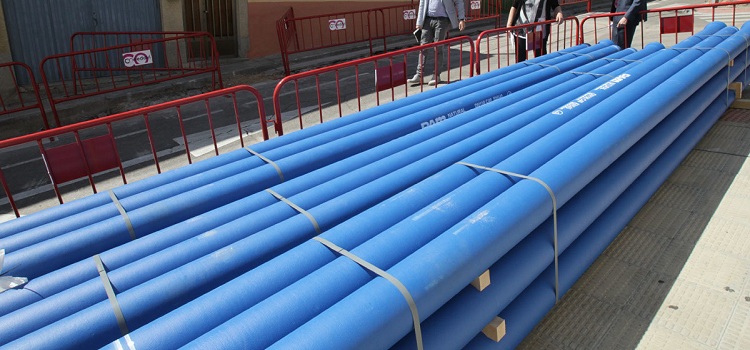

Water pipes are products that are used for the installation of water structures. Water pipes transport drinking water to consumers. Today, there are many varieties of these pipes, which differ in material and technical characteristics. To select the right elements of water supply, you need to familiarize yourself with all their types and features.

Content

Types of water pipes

All water pipes can conditionally be divided into three types according to the material of manufacture:

- metal;

- plastic;

- metal-plastic.

Helpful information! Metal products today are not so popular, as the development of modern industry has led to the emergence of new materials.

Features of metal parts depend on the material from which they are made. Consider these materials:

- steel;

- cast iron;

- copper.

Plastic products are made from various polymers and are characterized by simple installation and relative low cost. They are made from different polymers:

- polybutylene (PB);

- polyethylene (PE);

- polyvinyl chloride (PVC);

- polypropylene (PP).

For the production of plastic pipes, polyethylene, polyvinyl chloride, polypropylene and other types of similar materials are used.

Metal-plastic water pipes combine the properties of plastic and metal parts and are very popular for laying water and heating communications.

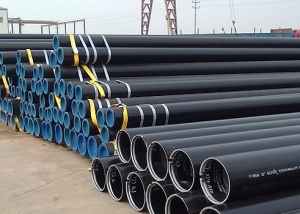

Steel pipes for water supply

Steel pipes under water are characterized by high strength indicators and are considered a very reliable option for the installation of the pipeline. In urban high-rise buildings, risers are mounted from steel parts. The main disadvantage of using products made of this material is considered to be low resistance to corrosion. Over time, the internal walls of the steel parts become clogged, resulting in the termination of the functioning of the pipeline.

In order to cope with the corrosive effects on the external and internal walls of steel parts, a protective layer of zinc is applied. Such parts are called galvanized and are a more reliable option compared to conventional products from this material that are not equipped with a protective layer. Among the other features of such products can be distinguished by high thermal conductivity, high weight and operational life, which is approximately 30 years.

Docking of individual elements of the pipeline from steel is carried out in three main ways:

- using special connecting fittings - couplings;

- through press fittings.

- by welding.

Galvanized parts are connected only in the first two ways, since welding destroys the protective anticorrosive layer.

Cast iron pipes for water supply

Cast iron pipes have good resistance to corrosion, however, are distinguished by their large weight.The installation of such products requires enormous labor, therefore, such products are not very popular and are considered a relic of the past.

The walls of cast iron products are characterized by a rough structure, which affects the throughput indicators not in the best way. To date, they are most often exploited when laying sewer communications.

The operational life of such products reaches 100 years. The articulation of individual pig-iron elements of the pipeline between themselves is carried out using special sealing gaskets and sockets. Depending on the mass, all cast iron products are divided into three main types:

- medium;

- heavy;

- very heavy.

As a rule, a special protective layer is applied to these products to protect them from corrosion. They are distinguished by high strength characteristics, resistance to temperature changes and have a low coefficient of linear expansion.

Copper pipes for water supply

Copper alloy products are rarely used when laying pipes for drinking water. This is due to the fact that they are of high cost and are considered elite. However, the installation of a water supply structure made of such material, as a rule, justifies the costs.

They are distinguished by high technical characteristics. The operational life of such products is at least 70 years. Over time, the copper parts of the water supply do not wear out, and also do not lose their performance. Let's consider other advantages of copper elements:

- products from this plastic alloy have bactericidal properties, which affects the quality of drinking water. A copper pipe for water, without a doubt, is considered one of the best options;

- a copper water supply system has a presentable appearance and is able to become a decoration of any interior;

- such products are resistant to ultraviolet radiation;

- copper parts are resistant to atmospheric pressure drops;

- have high resistance to corrosion;

- the operating temperature range for such products ranges from –200 to +500 ° C.

Important! To connect the individual parts of the copper pipe, fittings of the same material must be used to avoid the oxidation reaction.

Copper parts are equally well suited for both cold and hot water installations. The weight of such products is quite small, and the installation is simple due to the plastic qualities of the copper material. If required bend the copper pipe, this can easily be done without special equipment, and the connections can be made using high-temperature soldering or fittings.

Plastic pipes for water supply

Plastic pipes today are the most popular option for laying water pipes. This is due to their high technical characteristics, low weight and affordable price. The service life of polymer parts, as a rule, is about 50 years under normal use. The main disadvantages of such products include: a high coefficient of thermal expansion and low resistance to ultraviolet radiation.

Polybutylene (PB). Such water supply elements are made of a very flexible material, which is characterized by good thermal conductivity. The maximum temperature of the working medium for polybutylene products reaches +90 ° C. Joint these products among themselves by means of welding equipment. The main disadvantages of polybutylene pipelines include weak fire resistance and intolerance to benzene. It is strongly not recommended to paint the water supply structure from this material.

Polyethylene (PE). Products made of this material are characterized by a high coefficient of elasticity and have sufficient strength characteristics. A water pipe made of polyethylene is the best suited for organizing water supply in a private house. The plastic characteristics of these pipes allow them to have good resistance to low temperatures. In addition, they have smooth inner walls and are resistant to the harmful effects of corrosion.

Consider the main disadvantages of PE pipes:

- poor resistance to high temperatures. Polyethylene parts are preferably used for the installation of communications transporting cold water;

- low resistance to ultraviolet radiation, so such pipes are laid in a trench way.

Separate individual elements of the polyethylene water supply system through special fittings or by crimping. Polyethylene pipes are divided into several types depending on the production technology. The most popular are products made of cross-linked PE. They are highly durable and are used for the installation of plumbing communications and heating systems. Such pipes are connected by means of press fittings, which is very convenient.

Polyvinyl chloride (PVC). These products are characterized by the lowest elasticity of all polymer pipes. They are highly resistant to ultraviolet radiation, and are also considered fire resistant, since they practically do not ignite. Polyvinyl chloride products are joined together by gluing. The main disadvantage of such products is that chlorine is used in their production, so such pipes are not environmentally friendly.

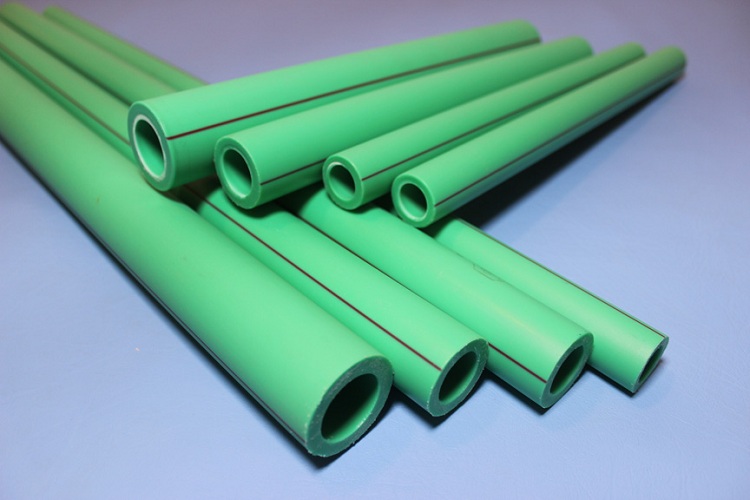

Polypropylene pipes - the most suitable products for the installation of water pipes inside houses and apartments

Polypropylene (PP). Polypropylene products are one of the most popular and are used for laying various communications:

- cold water supply;

- hot water supply;

- heating systems;

- sewer pipelines.

They are able to withstand high temperatures, as well as products from cross-linked PE. However, unlike cross-linked PE pipes, they are more affordable and easier to install. The articulation of the individual elements of a polypropylene water supply system is carried out by two methods:

- welding;

- soldering.

Metal-plastic water pipes

Metal-plastic products used in laying communications for drinking water are very popular today. As mentioned above, they combine the properties of metal and plastic pipes. Metal-plastic parts consist of three layers:

- inner polymer layer;

- middle metal layer;

- outer polymer layer.

Such a structure allows these pipes to be quite durable and at the same time to have high flow rates due to the inner plastic wall. Also, the metal-plastic pipe is resistant to corrosion, quite elastic. Such pipes have a small mass, which contributes to a convenient and efficient installation of plumbing communication.

Helpful information! The metal layer between the two polymer layers, as a rule, is represented by aluminum. It is desirable to select the connecting elements of such pipes from the same material in order to avoid oxidation or to exclude the possibility of contact of the aluminum layer with the connecting parts of other materials.

The maximum temperature values for such products reach +95 ° C, and with short-term exposure - up to +110 ° C. The main disadvantage of these products is the fact that under mechanical stress they are quite easy to damage.

Assortment of water pipes

The range of metal products, among which steel and copper pipes can be distinguished, is regulated by the relevant regulatory and technical documentation. Plastic and metal-plastic parts are standardized similarly.

GOSTs indicate all the necessary geometric parameters for the above pipes. Steel water pipes (according to GOST 3262–75) have 25 varieties that differ from each other in standard sizes. The cross-sectional indicators of steel parts vary from 6 to 150 mm.

The range of copper products used for the installation of plumbing communications is regulated by GOST 52318–2005. Copper pipes have 26 varieties, the cross-sectional indicators of which can be from 6 to 267 mm. The wall thickness of such products varies from 1.5 to 3 mm.

PE and PP products are regulated by GOST R 52134-2003. In accordance with the assortment of water pipes from these materials, 34 main varieties of products with individual sizes are allocated. However, only 15 varieties are used when laying water structures. The cross-sectional indicators of these products vary from 10 to 160 mm. Metal-plastic products for the installation of water structures are regulated by GOST R 53630-2009. In accordance with this standard, 11 main varieties can be distinguished, the range of section indicators of which is from 14 to 110 mm.

According to the relevant GOSTs, it is possible to make the calculations necessary for the installation of communication (for example, calculate the weight of pipes with water). Regulatory documentation includes all the necessary tables and formulas.