The volume of water in the pipe, like some other parameters, must be calculated when laying communications and performing repair work. Inaccurate calculations can turn into troubles in the form of excessive costs for transportation and installation. Where the worst consequences of negligence will be insufficient or excessive pressure in the system, which will lead to inevitable alterations due to poor performance or premature wear.

The amount of working medium that will be transported through the pipeline depends on such a parameter as the volume of the pipe

Content

How is the calculation performed at an industrial facility

The volume of the water, gas, sewer or heating pipe is calculated in two ways:

- External or actual.

- Internal or useful.

Before calculating the volume of the pipe, it is necessary to determine what kind of form is it in question. If you want to calculate the volumes of gas or liquid that will be pumped, then the calculation refers to the internal or useful form.

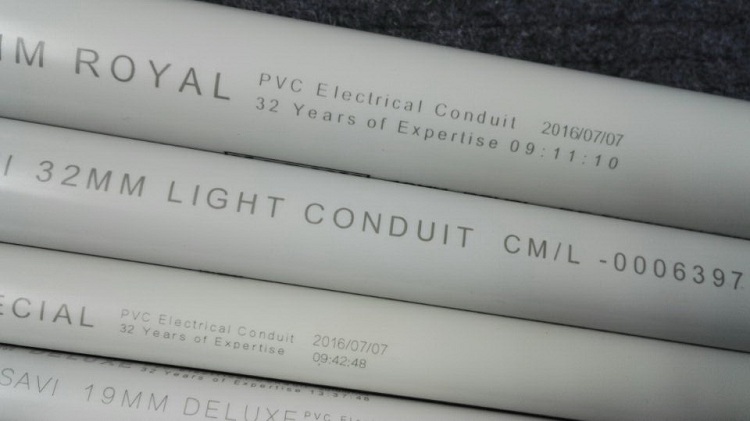

At large facilities, the beginning of work is associated with an incoming inspection aimed at checking the pipes for the presence of:

- accompanying documentation;

- certificates

- markings applied by the manufacturer on the surface of the products.

At this stage, they receive all the necessary information about the pipe, including nominal sizes, which allows the required calculations. In order to calculate the volume of the most common pipe with a circular cross section, you need to get data on its length and diameter.

Good to know! The actual length at the production site is measured using a building tape measure or measuring wire. At the same time, existing deviations from the data entered in the factory documentation are noted, and their compliance with the standards established by GOSTs.

Reconciliation of the outer diameter is carried out using the formula:

Here the following quantities are involved: D - outer diameter; L - the length of the outer circumference of the product; π - 3.14; ∆p is the thickness of the material used to make the construction tape; allowable allowance of 0.2 mm, related to the fit of the measuring tool to the surface of the product.

When conducting verification of the outer diameter, the values of deviations and errors established by GOSTs are taken into account.

How is the calculation of the external (actual) volume of a round pipe

The main value required during the calculations will be the diameter of the product. It should be borne in mind that measurements of steel pipes are traditionally made in the so-called imperial system, operating in inches and fractions of inches. Translating into a more familiar metric system, we take the size of an inch for 25, 4 mm. However, for the diameter of the pipe in the usual version it is taken as 25.5 mm, in the reinforced version as 27.1 mm. It is customary to neglect minor deviations, using the dimensionless conditional pass - Ду, determined using special tables in the calculations.

The joints of steel pipes with the diameter indicated in the imperial system - in inches, with plastic, aluminum or copper, the diameter of which is usually indicated using the metric system, in millimeters, is carried out using special adapters.

Calculation of the volume of water for the heat supply system is reduced, as usual, to the determination of the need for non-freezing liquid in order to avoid costs when surpluses appear. Calculations are reduced to using the dimensions of the expansion tank, measuring its diameters:

- external;

- the internal cavity.

When measuring the pipe diameter in the metric system, you should know how to correctly translate the resulting value in inches

The cylinder volume formula is used:

V = πR2H.

Here we are dealing with V - the desired external (actual volume) of the round pipe; π - 3.14; R is the outer radius of the product; H - cylinder height or pipe length.

Calculation of the internal (useful) volume of a round pipe

Such an indicator as wall thickness has a rather significant effect on determining the volume of pipes, determining the difference between external and internal (useful and actual).

Note! Since it is customary to operate with the supply of steel water and gas products only with the nominal condition Du and type (light, ordinary or reinforced), for calculating the volume you have to refer to the tabular data contained in GOST 3262-75.

Work with the GOST table is carried out in the following order:

- From the left column, the conditional pass - Du and the corresponding value of the outer diameter in the next column are taken.

- Knowing the type of pipe, the doubled wall thickness is subtracted from the outer diameter.

- The obtained value of the internal diameter by dividing by two turns into the value of the radius of the internal section.

To calculate the area of this section, use the formula

S = πr2, where:

S is the desired area; π - 3.14; r is the radius of the inner section.

The definition of the internal (useful) volume of a round pipe is carried out by means of the formula

V = SL, in which:

V is the desired internal (useful) volume; S is the internal cross-sectional area; L is the length of the pipe.

We will calculate the net volume of an ordinary pipe with a nominal bore equal to 100. The tabular value of the outer diameter in this case will be 114 mm, and the wall thickness - 4.5 mm. After subtracting 114 - 2x4.5, we get the value of the inner diameter - 105 mm, half of which will be a radius equal to, respectively, 52.5 mm. For convenience, we will translate further calculations into meters - 0.0525 m. The cross-sectional area will be 0.0525 m, multiplied by π -0.16485 m3, rounded to 0.165 m3. For translation in liters, the resulting value is multiplied by 1000, we get - 165 liters.

How are pipe volume calculations with a cross section

As a rule, when describing the calculation of the volume of pipe rolling, by default they are talking exclusively about products of circular cross-section. However, in modern everyday life, profile pipes with a different cross-sectional shape are increasingly being included:

- oval;

- square;

- rectangular;

- trapezoidal.

With a rectangular section, the calculation of the volume of the pipe is carried out according to the formula V = SH (in expanded form - abH), i.e., data on the dimensions of the product — length, width, height — are required. With a cross section of 15x10 mm for a five-meter segment, we get 0.015x0.010x5, which equals 0.0075 m3 or seven and a half liters.

The calculations for a product with a square section are simplified, since it is necessary to know the values of only one side of the section and the length. The formula is as follows:

V = a2H.

With a section of 180x180 mm for a five-meter segment, we get 0.182x5, which is 0.16 m3 or 160 liters.

With an oval section, the formula is used:

V = SL.

The calculation of the oval cross-sectional area is carried out using the formula S = πav, where it is necessary to substitute the values of the length of the major and minor axes of the ellipse (oval).

The easiest way to calculate the volume of a square profile pipe, since all four of its sides are the same

The trapezoidal cross-section of the pipes, increasingly used, along with the rectangular one, for arranging the sewer or chimney, to determine the volume involves the use of the same formula V = SL. To calculate the area of the trapezoid, the formula S = 0.5 av is taken.

The appearance of an increasing number of special computer programs for carrying out calculations in relation to pipe rolling of various profiles can significantly simplify the process. It is enough to use the services of an online calculator and enter the available data in order to instantly get the necessary results.