Heavy-duty heating systems from metal pipes are gradually becoming a thing of the past. They are being replaced by polymeric materials. Polypropylene pipes have excellent qualities: their assortment is quite large, and the technical characteristics of each species are different. To understand which polypropylene pipes for heating are better, you need to understand the properties of the material and the requirements for the heating system itself.

Content

- 1 Varieties of propylene pipes: which are better for heating?

- 2 Technical characteristics of polypropylene pipes for heating

- 3 How to choose polypropylene pipes for heating: diameters and assortment

- 4 Do-it-yourself heating from polypropylene pipes in the apartment

- 5 Do-it-yourself polypropylene heating in a private house

Varieties of propylene pipes: which are better for heating?

A decade ago, conventional polypropylene (PPR) was widely used for heating systems. But in its pure form, this material showed itself not in the best way, which is why its rating is now quite low. The service life of polypropylene was significantly different from the declared, and pressure and high temperatures became the cause of its deformation. The use of reinforcement made it possible to preserve the advantages of polypropylene and save it from significant disadvantages. Therefore, now the best polypropylene pipes for heating can be called the following:

PPR pipes with aluminum reinforcement. The use of aluminum foil literally gave new life to pipes for heating made of polypropylene. The metal layer, as it were, holds the polymer, protecting it from excessive expansion. A layer of aluminum sheet can be located both on the pipe surface and in the middle, between two layers of propylene (“sandwich”). Such products need to be cleaned, otherwise aluminum and PPR will delaminate at the place of welding.

Important! When choosing insufficiently high-quality polypropylene pipes for heating with an aluminum layer there is a big risk of sticking up the material: such products are easy to fake. Buy Reinforced PPR pipes only from trusted suppliers.

PPR pipes with fiberglass reinforcement. Very high quality and durable products. An excellent degree of reliability is achieved due to the monolithic design. Such pipes, unlike reinforced with aluminum, are literally cast, and therefore have earned a high rating and a lot of positive reviews. Fiberglass is actually a polypropylene composite, so the reinforcement will not detach from the main walls of the pipe under any conditions. Accordingly, such a pipe propylene for heating can not be cleaned before installation.

Of all types of polypropylene pipes, models with a reinforcing layer are the most suitable for heating.

Reinforcement successfully copes with reducing the effect of thermal expansion, but, unfortunately, does not eliminate it completely. Both those and other polypropylene pipes as a means for installing heating have good characteristics: a budget reference and personal preferences will help you choose between them.

Technical characteristics of polypropylene pipes for heating

There are many variations of polymer pipes on the market, but only polypropylene is recommended for hot water supply and heating. Materials such as PVC or HDPE are too soft for this purpose, they are better suited for supplying cold water, some for sewers. The main features that allow the use of polypropylene pipes in heating systems are high strength with sufficient lightness, as well as the ability to maintain performance in aggressive environments.

Polypropylene pipe, suitable for heating a private house or apartment, has the presented technical characteristics:

The ability to withstand powerful pressure. In general, PPR pipes can be installed on any systems that currently exist. The pressure that polypropylene pipes for heating can withstand directly depends on the constant working temperature of the water: the stronger the heating, the less pressure will be allowed. Most polypropylene products calmly withstand pressure of 4-6 atmospheres, despite the fact that the system will heat up to +70 degrees.

PP pipes are suitable for installation in any heating system, as they can withstand the pressure maintained in the networks

Heat resistance. The optimal operation of the polypropylene heating pipe will be ensured even at an ambient air temperature of -15 degrees. This indicator is not particularly significant in practice, but once again proves the strength of PPR products. The temperature characteristics of these pipes will be as follows:

- fragility appearance temperature - from -5 to -15 degrees;

- softening temperature of the polymer - from 110-140 degrees;

- melting point - from 140 to 170 degrees.

These characteristics make it clear that the use of high-quality polypropylene pipes for heating is justified and safe in all modern systems. The heating system can heat up to the specified level of softening only at a very high coolant temperature (up to 95 degrees), and such it happens in very rare cases. Short-term temperature jumps can be allowed without harm to the integrity of the polypropylene.

Low degree of thermal conductivity. Condensation does not form on the surface of polypropylene heating pipes precisely because of this property. The temperature of the pipe itself will be as close as possible to the temperature of the coolant.

Corrosion susceptibility. Polypropylene pipes for heating are much better able to withstand the influence of various adverse environments. Unlike metal products, they do not react in any way to prolonged contact with moisture. Salt and other impurities, which are only found in tap water, are not at all afraid of polypropylene. In order for the decomposition of polypropylene to occur, the material must react with a potent acid. Which in everyday conditions, of course, does not happen.

For uninterrupted operation of heating and its durability, it is important to choose the right fittings for pipes

Long service life. Manufacturers promise that when using polypropylene pipes in heating, they will not have to think about installing new structures for 50 years. This is a fairly high indicator, since the service life of, for example, steel pipes usually does not exceed 20-30 years. Cast iron pipes have a longer service life, but their installation is now not popular.

The service life of a polypropylene heating pipe will depend on factors such as constant pressure, system design, and temperature differences. Also, how correctly the choice of connecting elements was made directly affects the service life indicators of polypropylene heating pipes.

How to choose polypropylene pipes for heating: diameters and assortment

When planning polypropylene heating, the main criterion for choosing pipes is their diameter. The choice of pipes for this parameter is justified because each diameter is designed for a specific pressure in the system and its purpose. Consider exactly which variations exist:

- up to 16 mm. Small diameters of PPR pipes are a good choice for creating a system of underfloor heating. The lack of flexibility in polypropylene makes it somewhat difficult to connect floor heating, but adapters can be used to correct this drawback.

- 20-25 mm. This type of polypropylene product is optimal for heating a private house or network in an apartment. A simple system is mounted using pipes with a diameter of 20 mm, for risers you will need pipes of 25 mm.

- 25-32 mm. They are used when the connection of central heating in apartment buildings is required.

- from 200 mm. Such polypropylene pipes are used for heating crowded places: hospitals, hotels, buildings of universities and schools, large shops.

Another item in the assortment of pipes made of polypropylene for heating will be their marking. It has the form PN **, where ** is the technical characteristics of the pressure that these products withstand:

- PN10. A pressure of 1 MPa is allowed, a constant water temperature should not exceed 45 degrees when operating in a floor heating system and 20 degrees for hot water supply systems. The most inexpensive type of polypropylene for heating, which is better not to use for the main system in the apartment or for heating a private house. Such pipes are available only with a thin wall (1.9-10 mm);

- PN16. They carry pressure up to 1.6 MPa, temperature rise is allowed up to 60 degrees. With sharp temperature jumps, the service life of such PPR pipes can be minimized. Is it possible to put such polypropylene pipes for heating - you decide, but for reinsurance it is better to turn your choice to more durable models. Their wall thickness starts from 3.4 mm;

- PN20. Universal option: they withstand a working pressure of 2 MPa, the heating temperature of the coolant is 80 degrees. It is better to choose this variety for hot water supply, provided the wall thickness is in the range of 16-18.5 mm;

- PN25. The most effective polypropylene pipes for heating with excellent technical characteristics. They withstand pressure reaching 2.5 MPa, and are available only with reinforcement.

Do-it-yourself heating from polypropylene pipes in the apartment

For residents of apartment buildings, a situation is familiar when replacement of an old cast-iron pipeline is necessary. Replacing heating pipes in an apartment is a rather complicated undertaking, but even here it is quite possible to do without the help of professionals.

A self-designed new heating system in an apartment can have good performance, if you follow the procedure and safety rules. Replacing old heating pipes in the apartment with polypropylene will look something like this:

- coordination of work with municipal services. The first and very important stage, which will give you permission to shut off the water supply and discharge it from the system;

- coordination of work with residents of the apartment above and below yours. Replacement of risers will be needed not only in the apartment where the repair is carried out. However, if the dismantling of the riser is not possible, you can choose special adapters from cast-iron pipes to plastic;

- dismantling of old heating. Old cast-iron pipes lend themselves well to dismantling, but this procedure requires compliance with certain safety rules. The fragility of cast iron depends on how long the system used. Old pipes break very quickly, breaking into small pieces. When struck with a metal hammer, fragments fly off from the iron, which can fall into the pipeline: the water supply system may become clogged. Therefore, for such purposes, it is better to choose a rubber or wooden butt, which everyone will probably find at home. Disassembly should be carried out wearing a respirator and glasses;

- a diagram of the new system is formed, the radiator is mounted on a given perimeter;

- assembling polypropylene heating pipes and connecting a radiator;

- check system for leaks. The test procedure is carried out under strong pressure - 1.5 times higher than normal operating pressure. If the old system was replaced with a new two-pipe system, it is worth letting the water back in the test direction.

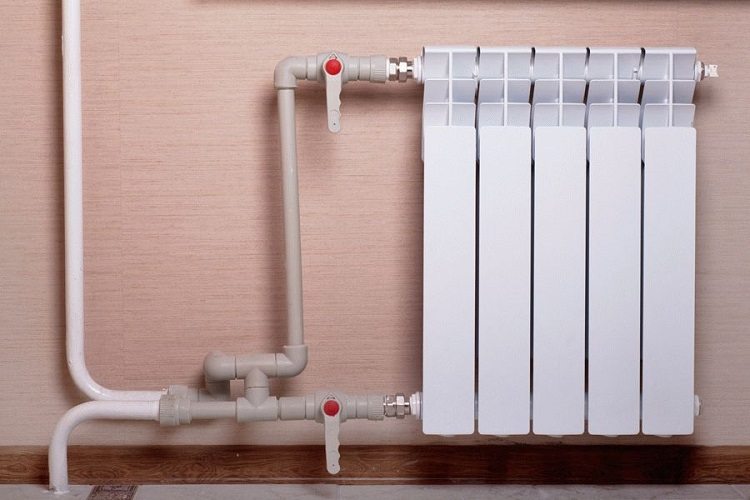

In apartment buildings, it is possible to replace metal heating pipes with polypropylene ones, either completely or partially

First of all, you need to choose the optimal type of system. The heating system can be single-pipe or two-pipe. The number of radiators and, accordingly, the cost of work will depend on this. A two-pipe system requires more radiators: if there are more than 8, then a polypropylene pipe with a diameter of 32 mm will be used for such heating. If you choose a one-pipe home heating system from polypropylene pipes, the cost of its arrangement will decrease, but the heat will not be distributed evenly. Each subsequent radiator will be cooler than the previous one. The circuit can be supplemented with thermostat valves that regulate the power of each radiator.

Whatever heating system is planned, it is necessary to place a valve for air discharge in the upper part of the radiator - a Mayevsky crane. In the lower parts of the hole are corked.

Important! When screwing the plug into the radiator inlet, it is necessary to clean the blade of the knife from the influx of paint and any other contaminants. This applies even to new radiators.

Do-it-yourself replacement of the heating system from polypropylene pipes is done using fittings, clamps, couplings (plugs, corners, tees). Which fasteners and connecting elements will require the replacement of pipes depends on which heating scheme has been selected. Replacement of polypropylene pipes is carried out using a welding machine. The heating time for each type of PPR pipe will be different. The most common polypropylene pipes 25 mm and 32 mm require 7-8 seconds for reflow. If replacing with aluminum reinforced PPR pipes, do not forget to pre-strip the foil before soldering.

Do-it-yourself polypropylene heating in a private house

For a private house, the best choice would be a two-pipe system scheme. From an aesthetic point of view, it is better to make a closed version of the location of the system, but technically hide pipes The wall is quite complicated.

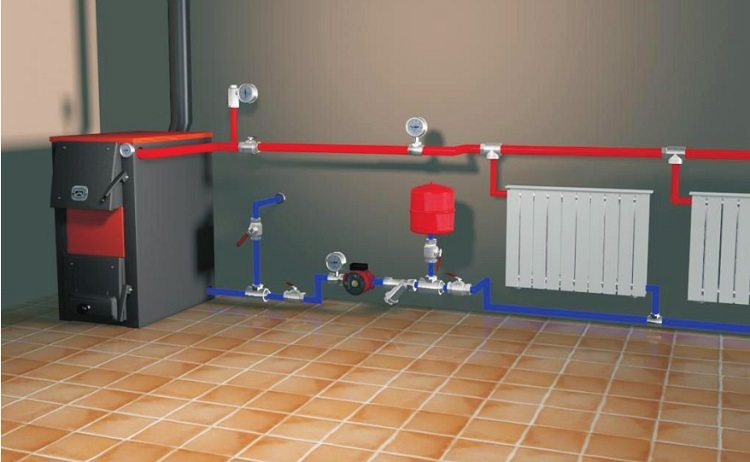

The development of a heating scheme from polypropylene pipes also includes a heat source of a private house. The boiler can be solid fuel, gas or electric. Electric ones are considered the safest - if you plan to make a heating circuit from polypropylene pipes with your own hands, it is better to choose this option. A solid fuel boiler is difficult to maintain, and connecting heating pipes to it requires special skills - for this it is better to invite professionals. A connection to a gas boiler makes sense if gas is connected to the house.

What circulation method will be chosen for the home heating system matters. There is a pumping and gravity circulation system. In the first case, the supply and circulation of water in the system will occur due to the operation of the pump. If gravitational (natural) circulation is used, it is imperative to install an air vent and an expansion tank, which serves to protect against pressure surges. If the heating scheme involves an upper wiring, these elements of the system are installed in the attic of the house.

Important! As the work of the heating system, it is important that the correct assembly of the booster manifold (pipe) is the vertical section of the pipe connected to the heating boiler. The diameter of the rest of the structure will determine which polypropylene pipe to choose for the heating booster: if the main pipe is 32 mm, the diameter of the pipe will be at least 40 mm.

Gravity (natural) heating system made of durable polypropylene is very simple and quite durable, its device does not require additional costs for pumping equipment. But the gravitational system also has some disadvantages, including a limited radius of action (not exceeding 30 m) and a long time to be included in the work.

For a house with a large area, you need to install a system with forced circulation, but it will require more consumables

The gravity system can be selected for a small private house, provided that the expansion tank is in a relatively warm room (to prevent freezing of water in it).

The radiator of the heating system is connected to polypropylene pipes in the following ways:

- diagonal type;

- side;

- lower.

The diagonal scheme involves connecting the supply pipe to the upper pipe, connecting the outlet pipe to the lower radiator pipe. It is noteworthy that the heat loss with this method does not exceed 2%. The diagonal connection is used for extended circuits (10-12 radiators). With a lateral type of connection, both the supply and outlet pipes are on the same side of the radiator: the inlet is at the top and the outlet is at the bottom. This method is very effective and is often used in apartment buildings. The lower circuit (“Leningradka”), in which the radiator is connected on a bottom-to-bottom basis, is not recommended for high-rise buildings, but is acceptable for autonomous ones. The lower wiring can be hidden if necessary in the floor.

Based on the information provided, the answer to the question "Can I use polypropylene pipes for the installation of a heating system" will be completely unambiguous. Products from PPR - this is not only a budget, but also a completely reliable option. In the ranking of polypropylene pipes for modern heating systems, reinforced products occupy a special place, and such structures will be the best choice.