Since ancient times, heating systems are based on metal pipes. Their demand is due to high reliability and durability. Even despite the emergence of new modern materials, steel pipes for heating are still relevant today. They withstand enormous mechanical loads and high heat carrier pressure, the temperature of which can reach + 100˚С. And if the pipe freezes, it can be heated using open flame.

Steel pipes have been used for more than a decade for the installation of heating systems for residential and industrial facilities

Pros and cons of steel pipes

Technical characteristics of steel pipes for heating depend on the technological features of their production. Products can be welded or seamless. The former are stitched from a metal sheet, and the latter are formed on sophisticated equipment.

The main advantages of a steel pipe for heating include:

- high thermal conductivity. This moment is very important for the organization of heating systems in residential buildings. The metal surface transfers heat to the airspace of the room, thus partially fulfilling the function of a heating device;

- low thermal expansion. This property determines the absence of the need to use thick-walled products;

- high gas tightness. The value of this characteristic reaches almost one hundred percent mark. To create a full-fledged closed heating circuit without fulfilling this condition is unrealistic;

- strength. Due to this property, high-pressure lines are created only on the basis of metal pipes;

- availability. The relatively low cost of steel plays an important role in creating budget options for heat supply.

Of the shortcomings, experts distinguish:

- susceptibility to corrosion. Metal poorly resists exposure to aggressive environments and oxidative processes. But galvanizing steel pipes can increase their service life by 10 ... 15 years, that is, almost 2 times;

- big mass. Significant physical efforts will be required to lay the pipeline;

- rigidity. You can bend the pipe only by heat. When forming the line, the connection of steel pipes requires curly elements.

- electrical conductivity. This property of metal is of particular importance when arranging a heating system based on an electric boiler.

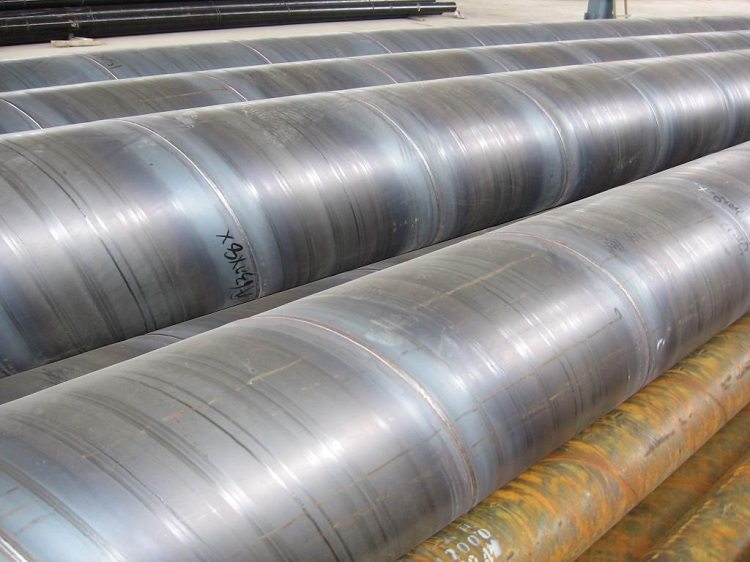

Varieties of Steel Pipes

The metallurgical industry produces only three types of steel pipe products.

Black steel. Pipe products of this type found wide application in the 70s-90s of the last century in the creation of water and heat pipelines. Most often, an electric-welded VGP pipe was used for this purpose, the technical characteristics of which correspond to the requirements of GOST 3262-75.

Helpful information! When choosing the elements of a heat supply system, many homework masters take into account, along with the service life of steel pipes, the fact that they are easily welded, and thereby facilitate the installation of the system.

The main drawback of this type of metal products is their susceptibility to corrosion in contact with water. For this reason, rust flakes appear in the coolant, and the pipes themselves are overgrown with deposits. The combination of these factors leads to a decrease in the throughput of the heating pipeline. That is why it is possible to buy steel pipes today at a relatively low price, but they will have to be changed quite often.

Galvanized steel. The zinc coating layer, as mentioned above, is designed to counteract the phenomenon of corrosion and increase the service life of pipe products made of black steel. Coping with the task, galvanizing is not completely, but only slows down the corrosion of the base metal.

According to experts, galvanizing is the most stable and durable material, the technical characteristics of which make it possible to create centralized heating with its unpredictable pressure surges and temperature schedule. In autonomous heating systems that allow operational control of operating parameters, it is possible to install cheaper pipes made of metal-plastic and polypropylene.

The galvanized elements of the heating pipeline have only two serious drawbacks:

- a weld breaks the zinc layer inside the pipe, creating a weak spot for corrosion. This inevitably leads to a decrease in the service life of the heat supply system. And mounting on a thread will take a lot of time and effort.

- the cost of galvanized products is much higher than the price of heating pipes made of black steel, metal or plastic.

Pipes for heating need to choose galvanized or stainless, they are resistant to corrosion and last longer than usual

Stainless steel. Theoretically, the use of seamless stainless steel pipes or welded products makes risers, as well as eyeliners, almost eternal. But such a solution is not popular due to the complexity of processing corrosion-resistant steels and their high cost.

Against this background, the use of a corrugated stainless steel pipe is much more profitable.

- during installation, you can do with a couple of gas keys and an inexpensive pipe cutter;

- recommended working pressure at a temperature of + 100˚С is. Such an indicator is not available to any plastic;

- pipes can take any complex configuration and are easily bent by hands.

Note! If your family has small children, they will inevitably use radiator connections as a crossbeam or support, which will cause deformation of these elements of the heating pipeline. A stainless steel, in fact, like any metal, loses its strength upon repeated bending and can even break.

Connection methods

The most common ways to connect steel pipes are through threading and welding. But modern technology does not stand still, but is constantly being improved. Today, there is already the possibility of joining steel pipes without welding and threading. However, there is one limitation: in this way elements of the pipeline, the diameter of which does not exceed 60 cm, can be hermetically joined.

Most often, a special coupling is used to connect steel pipes without welding. Its design includes:

- housing;

- four washers and two nuts;

- two rubber pads.

For connection, it is necessary to thread the ends of the pipes through the gaskets, washers and nuts and join them inside the housing. From tightening the nuts, the gaskets are squeezed, ensuring tightness. If its level is insufficient, an additional spacer ring should be added.

The success of this operation depends on the correct selection of the diameter of the coupling. And if everything is clear regarding the too small value of this parameter - the pipes simply do not fit into its body, then the coupling with a too large cross section will not create a tight connection.

The flange method is another alternative type of threadless joint for steel pipes. It should be understood that there is no thread on the surface of the pipes and is only available on fittings.

The connection of pipes using flanges is considered one of the most reliable, but subject to its correct execution

This method of docking involves taking into account the following points:

- misalignment of nuts is not allowed. That is, it is necessary to tighten them not around the circumference, but diametrically against each other;

- the gasket should be made of asbestos cardboard;

- bolts should not protrude more than half from the nuts;

- the outer diameter of the gasket should not touch the bolts, and the size of the inner should be slightly larger than the pipe section;

- in order not to reduce the tightness and the period of trouble-free operation of the pipeline, several gaskets should not be used for one flange.

In accordance with the technical characteristics of the intended operating conditions, the flange connection will be the most reliable.

In conclusion, it should be noted that the installation of the heating system can only be entrusted to an experienced master. So you exclude the possibility of domestic problems for you and your neighbors.