The closed heating system of a private house is one of the options for organizing heating in a private house. From a technical point of view, a closed, and indeed any heating system is a structure of elements that are connected to each other via plastic or steel pipes in a strictly defined sequence. The main advantage of closed heating communications can be called the fact that it has a longer operational period due to high leakage rates.

A closed heating system can not be attributed to the budget option, but it has many advantages over an open

Content

- 1 Types of heating systems

- 2 Advantages and disadvantages of a closed heating system

- 3 Methods for circulating coolant in a heating system

- 4 Elements of a closed heating system

- 5 The right boiler for a closed system

- 6 The choice of expansion tank

- 7 How to fill the system with coolant?

- 8 Why does the pressure drop in a closed heating system?

Types of heating systems

Regardless of which heating structure is used, the principle of operation remains the same - the coolant is heated in the boiler to the desired temperature and circulates through the pipeline to the heating appliances, gradually cooling. After the heat transfer agent transfers its heat, it returns to the boiler and the process repeats.

As a coolant, as a rule, two substances act:

- water;

- antifreeze.

There are two main types of heating systems, which are classified by the design of the expansion tank. An expansion tank is a device that compensates for the thermal expansion of the coolant when it is heated.

The heating system can be closed and open. Consider these two types in more detail:

- Open. In this design, the expansion tank is leaky. Therefore, when laying such communication in a private house, any suitable capacity can be used as a tank. However, there is one very important rule that must be observed when installing an open heating structure - the expansion tank must be located above other elements of the system.

- Closed. In a closed heating system, the tank is leakproof. Due to this, such a capacity can be mounted anywhere in the system.

Helpful information! Due to the high sealing performance of such a system, it becomes possible to increase pressure. The contact of the working medium with oxygen is also excluded. As a result, the corrosive effect is reduced and the operating life of the heating equipment is increased.

In some cases, the heating tanks are joined to the boiler (the so-called built-in tank). Tanks for enclosed structures are mainly represented by the membrane type.

Advantages and disadvantages of a closed heating system

Today, closed heating systems have become very popular. This is due to the fact that such heating structures have advantages over open analogues:

- such a system can function for a rather long period without human intervention, which indicates its autonomy;

- the possibility of using different coolants that evaporate in open structures;

- maintaining constant pressure indicators necessary for normal heating of a private house;

- installation of such a design, if desired, can be carried out personally;

- reducing the overall financial costs of organizing such a system;

- high heat transfer coefficient;

- eliminates the need for thermal insulation for the highway, there is no need to set clear angles of its inclination;

- no need to constantly add coolant to the system, since its evaporation is excluded;

- uniform heating of heating devices that affect the heating of rooms;

- reduction of corrosive effects on heating equipment;

- fast heating of the heat carrier.

Using antifreeze as a coolant for a closed heating structure is an excellent solution. This is due to the fact that in winter it is possible to use the heating system periodically, without fear of freezing of the coolant.

It is difficult to organize the natural circulation of the coolant in a closed system, so it is necessary to install a pump

Closed systems have some disadvantages:

- installation of a closed heating structure involves the purchase of a rather large expansion tank (it costs quite expensive);

- Another drawback is the constant need for electricity (for the circulation pump).

Methods for circulating coolant in a heating system

Each of the above systems is required to ensure the delivery of heat-conducting substance to batteries or radiators in a private house. There are two ways to perform this delivery. Consider them:

- natural circulation heating system;

- forced circulation heating design.

In the first case, a minimum of equipment is used to install the system. This affects the total cost of organizing heating in a private house. Natural circulation of water or antifreeze is a process as a result of which the movement of the coolant occurs from its thermal expansion. A closed heating system (with natural circulation) is usually installed for economic reasons, as its cost is lower than for communications with forced circulation of the coolant.

When heated, water (or another coolant) loses its density, so it becomes easier. As a result, the coolant is naturally delivered to heating devices, which include batteries and heating radiators. In radiators, heat exchange occurs between the coolant and the environment, which leads to cooling of the first. After cooling, the water is piped back into the boiler, displacing the heated water, which rises to the heating appliances. Thus, the natural circulation of the coolant in a closed heating system takes place and the house is heated.

However, such a system has its drawbacks, among which are: insufficient pressure in the system, uneven heating of heating devices.

The rate of natural circulation, as a rule, depends on several factors:

- the temperature difference between the cooled and heated coolant (in most cases it is about 10 degrees);

- the diameter of the pipes between the devices in the heating system, which affects the resistance to movement of the coolant.

A closed system with a pump will ensure uniform heating of all radiators in the house, regardless of their location and distance from the boiler

The operational characteristics of the heating structure depend on the location of its elements. For example, the boiler should be located at least 3 meters below the battery level.

Closed heating system (with forced circulation) provides for the installation of a special pump called a circulation pump.It performs the function of creating the necessary pressure difference for the normal movement of the coolant from the boiler to the radiators and vice versa. Such a system has some advantages. Consider them:

- faster heating of rooms;

- uniform heating of heating appliances;

- the ability to control and regulate individual parts of the heating structure, disconnecting one of the parts of the circuit if necessary;

- accumulation of air in the system is excluded;

- the use of a circulation pump allows you to perform a closed sample system using a membrane expansion tank;

- fuel economy.

Note! A forced circulation system does not need to increase the diameter of the pipes in order to achieve the required pressure values. This saves money when installing such a system.

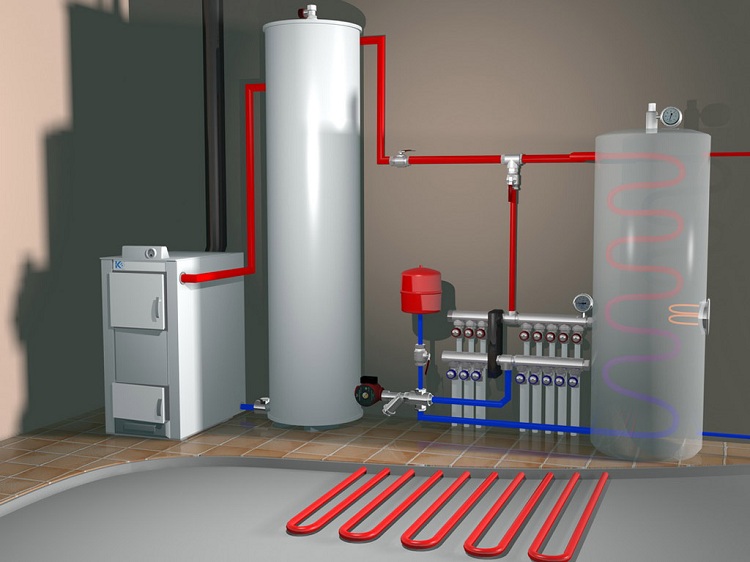

Elements of a closed heating system

Consider the elements of which any heating communication of a closed type consists of:

- boiler equipped with a safety group. The safety group can be mounted directly in the boiler or at the outlet of the device (in the supply pipe).

- pipes;

- batteries or radiators;

- convectors;

- in some cases - a pipeline in the floor (warm floor);

- circulation pump, which is necessary for the normal movement of a heated working environment. Such a device is mounted, as a rule, in a place where the temperature is the lowest (on the return pipe). This is necessary to exclude the possibility of overheating of the pump;

- expansion tank. As mentioned above, this device compensates for the temperature expansion of water or antifreeze.

The closed type of heating allows the installation of a “warm floor” system, the operation of which also depends on the circulation pump

These are the main elements that make up a closed heating system. There are also shaped parts, which include connecting elements - fittings, characterized by a variety of shapes and installation options.

The right boiler for a closed system

The closed heating system can operate autonomously. Experts recommend installing automatic boilers that perform work according to the parameters established after installation. In this case, no intervention by the owners is required, which is very convenient.

The main types of boilers, depending on the fuel on which they operate:

- gas;

- electric;

- on liquid fuel;

- on solid fuel.

The most suitable option for closed heating communications are boilers that use gas as fuel. When installing a gas boiler for a closed heating structure, it is possible to connect to a room thermostat system. This device allows you to set the required temperature in heated rooms, and the temperature accuracy is very high (up to one degree).

Some types of boilers can be connected with special weather sensors, which are installed outside the building and transmit weather information. According to their testimony, the boiler regulates the power and heating rate of the coolant.

It is also worth saying a few words about models that operate on electrical energy. There are three types of boilers:

- conventional boilers, including a tubular electric heater (TEN);

- induction;

- electrode.

The last two types are considered more compact and profitable, from a financial point of view. In addition, they have a lower coefficient of inertia, which is also an indisputable advantage.

Today, the most universal are considered boilers that use solid or liquid materials as fuel.

Note! When installing a device that operates due to the combustion of liquid fuel, it is necessary to equip a separate room (taking into account fire safety rules). And solid fuel appliances are allowed to be installed in the house.

Solid fuel boilers have the ability to organize automatic control of the combustion process, however, due to the specifics of the fuel, the efficiency of such an automatic system will be lower.

The calculation of the power of this device is quite simple, but there are some nuances. Experts advise choosing a boiler, guided by this calculation: 100 watts of power are needed per 1 m² of area. It is advisable to select a boiler with a power slightly higher. This is due to the fact that there are abnormally cold winters. The power reserve should be approximately 30-50%.

The choice of expansion tank

The expansion tank in closed systems is a tank with high sealing performance, which is divided in the horizontal plane by a special membrane. In the upper part of such a container may be an inert gas, which increases the operational characteristics of the device.

The principle of operation of this device is based on the temperature of the coolant. That is, while this indicator is low - the capacity will be empty. After the coolant is heated to a high temperature, the excess formed in the tank due to thermal expansion is removed. In this case, the membrane rises and the inert gas is compressed.

The process described above, as a rule, is fixed on the measuring device (manometer) and can serve as a signal to reduce the intensity of heating of the coolant. Some varieties of these tanks are equipped with a safety valve, which is necessary in order to vent excess gas.

The coolant in such a tank is gradually cooled and the inert gas pressure acting on it gradually squeezes the coolant back into the structure. After removal of the cooled coolant from the tank, the pressure is equalized on the measuring device.

Membranes for such devices are divided into two types, depending on their shape:

- dish-shaped;

- pear-shaped.

How to fill the system with coolant?

If the heating structure is connected to the water supply system using a ball valve, then it is not difficult to fill it: one person must open the tap alternately, and the other must let out excess air from the batteries. It is recommended to open the tap no more than a third, so that the pressure is not very strong.

The person who is in the boiler room must monitor the pressure readings on the measuring device. When this indicator reaches 2 Bar, it is necessary to stop filling the heating system with water, after which the second person, using special taps, removes excess air from the battery. After this, the procedure is repeated until the pressure indicator in the system reaches the calculated value.

To fill the system with a coolant that is not connected to the water supply, you need a pump (manual or electric), and a tank from which the coolant will be pumped into the heating communication. Before you start filling the heating system, you need to open the air valves on the batteries. Pipe filling is carried out using a pump after connecting the drain fitting to the pipeline. It is important to remember that you need to close the taps on the batteries in time to avoid leakage of the coolant.

After filling the system, it is necessary to launch it and check all the equipment.If the heating system is operating normally, does not leak anywhere and gives the desired pressure on the pressure gauge, then the injection was successful.

Why does the pressure drop in a closed heating system?

The closed heating structure must be leakproof. With a decrease in pressure in this system, there can be only one reason - leakage. In order to detect a leak, it is necessary to inspect the following structural elements in the system:

- joints of pipes and connecting elements themselves - fittings;

- automatic elements for air removal (air vents);

- all shut-off and control valves;

- safety valve;

- expansion tank. In this case, most likely, it is possible to detect a crack in the delimiting membrane.

Important! In order to eliminate the leak, in any case, you will need to remove the coolant from the entire system or from a separate section of it.

After repair, you will have to re-pump the working medium into the heating system. Experts recommend watching the manometer readings for several days.