Heat in the house is the main component of comfort. Housing heating is carried out in many ways. In multi-unit buildings, this is central heating. But in private homes are installed heating boilers that work with fire. Such units cannot be operated without a chimney device. Traditional pipes do not compete with new equipment. So, for the installation of a coaxial chimney, an increasing number of owners of private houses are deciding.

Content

Design features

The concept of “coaxial” provides for the presence of two objects inserted along a common axis in one another. Based on this definition, we can say that the coaxial chimney is a double-circuit design, including pipes of different diameters, which are located one inside the other. The contact details are impeded by the jumpers present inside the device.

Combustion products are led out through the inner pipe, and the outer one serves to supply fresh air, without which combustion is impossible. Having learned what a coaxial chimney is, one can draw the following conclusion: there is no need to specifically provide a constant flow of fresh air. But for traditional smoke exhaust channels this is inevitable. In addition, the installation of this device allows you to solve a number of problems inherent in standard chimneys:

- increase system efficiency. This is due to the fact that the air coming in from the outside is heated from the internal pipe that removes hot smoke;

- the risk of fire at places of contact between flammable surfaces and the flue duct is reduced. The inner pipe is cooled to safe temperatures due to its heat transfer to the external pipe;

- due to the high efficiency of the system, fuel is burned almost completely. Thus, the amount of unburned particles emitted into the atmosphere is significantly reduced, because of which it is not polluted. We make another conclusion: the installation of a coaxial chimney makes the boiler more environmentally friendly;

- the combustion process, starting with the supply of oxygen and ending with the removal of gases, takes place in a closed chamber, as a result of which combustion products dangerous to people do not enter the room. Therefore, it is not necessary to equip additional ventilation;

- the compactness of the device saves usable space;

- wide range of chimneys. You can choose a suitable sample for systems of any power.

Coaxial chimney consists of two pipes inserted into each other; one removes smoke, the second serves to supply air to the boiler

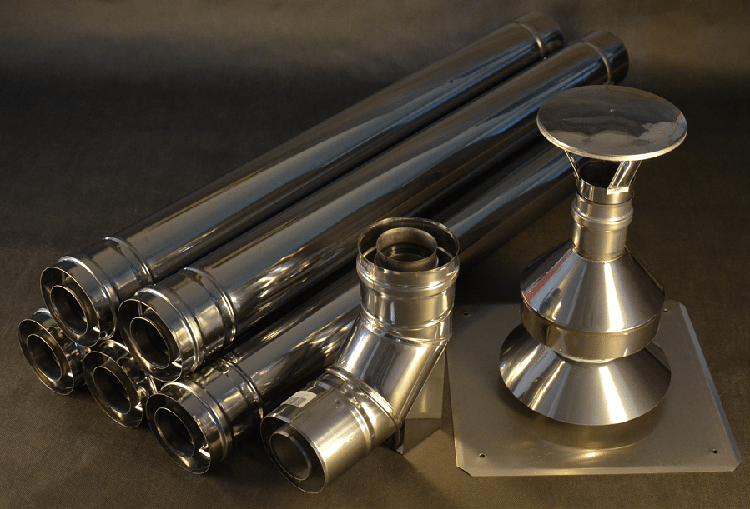

The main elements of a coaxial chimney

Consider in more detail the design of the coaxial chimney. You can call it difficult only with a big stretch.

- the inner pipe, the diameter of which does not exceed 80 mm, is made of stainless or galvanized steel;

- the outer pipe has a cross section of up to 125 millimeters.The specific value of this parameter determines the actual value of the diameter of the coaxial chimney. An external pipe is made from the same types of steel;

- knee. Performs the function of the transition element during installation work;

- adapter. With its help, the boiler is connected to the chimney;

- clamp It is used to give bonding elements of the chimney increased strength.

Good to know! Although galvanized is cheaper, stainless is preferable.

This standard set of elements can be optionally supplemented:

- corrugated pipe. Its use provides a more convenient installation of the pipe to the pipe of the heating unit;

- overlay decorating the place where the pipe enters the wall;

- flange for wall pipe laying.

Gas systems will not put forward any special requirements for a chimney system equipped in the above manner. Moreover! The requirements for the installation of a coaxial chimney do not provide for the organization of ventilation of the supply and exhaust type. And so that the boiler does not fail, you only need to listen to the recommendations. It concerns, first of all, condensate. Remember! It must be directed from the boiler, not to the boiler. To do this, it is enough to create a slight slope of the horizontal pipe towards the street. There is one more point: without a slope, coaxial chimneys are covered in ice crust very intensively in winter.

At the same time, such a good system has one significant “but”: not all boilers produced by modern industry can be connected to similar smoke removal systems. We are talking about models of heating units, the design of which is not equipped with a special turbine, which is a powerful fan. It is this element that creates a pressure differential, due to which hot air flies out, and cold air from the external environment is drawn into the combustion chamber.

Varieties of coaxial chimney

The main criterion for subdivision of these devices into types is the place of their installation.

- horizontal coaxial chimney. This type of exhaust pipe for a heating appliance is most widely used due to the ease of installation. The coaxial pipe is installed in a hole punched in the wall and walled up there forever. Such a chimney system is very convenient when creating individual heating systems in apartments of high-rise buildings, where there is no possibility to lay a chimney through the roof. One more advantage of such a technical solution cannot be ignored. It consists in the fact that the organization of a small slope of the coaxial chimney in an apartment building will allow condensate to drain onto the street by gravity without the use of additional devices;

- coaxial chimney of a vertical design. Most often used when installing boilers in private homes. It is displayed on the street through the roof. The disadvantages of the vertical coaxial chimney include the fact that at the stage of installation it is necessary to ensure the removal of condensate.

The horizontal chimney is more convenient to install and does not require special devices for condensate drainage

Helpful information! Knowing this problem, the manufacturer at his facilities equips the coaxial chimney pipes with a specially created condensate removal system.

Features of installation and connection to a gas boiler

We already know that a coaxial chimney can be installed both horizontally and vertically. The first option is much simpler, but due to poor natural traction, it can only be realized for models equipped with an exhaust fan.

Installation of gas chimneys is regulated by relevant regulatory documents. The basic rules that should be considered when installing a coaxial pipe are presented below.

Horizontal coaxial chimney.

- acquiring a set of such a gas exhaust system, the choice must be made according to its diameter. It should not be less than the cross section of the outlet pipe of the heating unit;

- in accordance with the regulated installation rules, the maximum length of a horizontal coaxial chimney should be made so that it does not exceed 3 meters. Some manufacturers, counting on the high power of exhaust fans, recommend long lengths for the models they produce;

- it is necessary to install a chimney with a slope of 3˚ to the side of the boiler for each linear meter of the pipe. Fulfillment of this requirement will create conditions for spontaneous runoff of condensate formed.;

- Choose a place for the hole in the wall, taking into account that the distance from it to the outlet pipe of the boiler is about 0.5 ... 1 meter. Then the chimney will not freeze inside during frost in the winter;

- if the boiler is installed near the window, the distance from it to the outer pipe of the horizontal coaxial chimney must be at least half a meter. Displaying this element of the chimney system under a window is strongly discouraged. In the absence of another possibility, the permissible location of the pipe is at least 1 meter below the window level. The distance to the gas supply pipe must exceed half the diameter of the coaxial chimney;

- the height of the outer pipe above the ground should be at least 2 meters. This will minimize the likelihood of contamination;

- the protruding part of the coaxial chimney located under the balcony or canopy must be of a certain length. It should fit into a semicircle centered at the point of exit of the lower surface of these building elements from the wall with a radius equal to their width.

Vertical coaxial chimney. When installing this design, you must pay attention to the following points:

- When assembling the chimney elbows for the gas unit, each top should be inserted inside the previous elbow and connected with clamps. If this rule is not observed, condensate will leak through the leaky joints, and will begin to drain along the outer wall of the chimney;

- for ease of maintenance and cleaning, as well as to collect condensate, the lower part of the structure must be equipped with a tee.

Good to know! Installing a deflector (or protective cap) it is forbidden to the exhaust pipe due to the possibility of icing. To protect the system from wind and precipitation, a cone-shaped tip is mounted on a coaxial vertical chimney.

It should be noted one more thing. In addition to use in private houses, there is a collective version of a vertical coaxial chimney in an apartment building. Such a chimney system makes the use of gas individual heating devices completely safe. A common chimney is installed at the stage of construction of a multi-story building.

Installation sequence and features

Any person with elementary skills in using a power tool can install a coaxial chimney with their own hands. This procedure consists of the following steps:

- a hole is made in the necessary place on the outer wall;

- an adapter is connected to the boiler;

- the chimney itself is connected to it using a crimp clamp. If it is necessary to supply the structure to the wall, a knee is used. All elements are fixed with the same crimp clamps;

- pipe outlet through the hole at the required slope;

- filling gaps with mineral wool or mounting foam;

- the pipe outlet is closed with a decorative overlay.

The pipe should be well fixed with clamps, and the place of its passage through the wall must be closed with special overlays

It should be noted that each turn of the smoke exhaust line requires a decrease in its length by 0.5 meters.

Proper installation of a coaxial chimney will prevent the entry of carbon monoxide into the living room, which is dangerous to human health. Typical errors most often made during installation of the flue system include the following flaws:

- Incorrect calculation and incorrectly completed assembly of the gas exhaust system. This can lead to the penetration of smoke through the joints of individual links in the channel.

- insufficient rigidity of the chimney fastening to the wall of the house. Most often, this drawback is fixed due to the use of inappropriate fasteners;

- the owner did not equip his house with thermal insulation between the wall and the roof. Its absence leads to a violation of the temperature regime where the chimney passes through the walls and roof.

Leading Coaxial Chimney Manufacturers

A large number of firms work in this segment of the global construction market. Below are only the most popular.

Baxi (Baxi). This company is part of the BAXI GROUP holding, founded in 1866 in England, which today unites 16 enterprises from 7 West European countries under one “roof”. The central factory is considered to be in Italy. Over a year, more than 500 thousand boilers come off its conveyor, and a coaxial chimney may be included in the delivery package of them at the request of the buyer.

Navien This brand is one of the largest manufacturers of boiler equipment not only in South Korea, but throughout the world. More than 80 percent of its products are sold in the countries of the Pacific, Japan, China, the United States, and since 2008, it has become available in the CIS.

Good to know! Coaxial chimneys manufactured by Navien are suitable for working with gas boilers of floor and wall type with a capacity of up to 75 kW.

Vaillant (Vailant). This German company was founded in 1874. Currently, it is part of the Vaillant Group, which is headquartered in Germany. This year, this company produces more than 3 million units of heating equipment, optionally equipped with coaxial chimneys. The key to a long and successful operation of the boiler is the compliance with the size of the pipes.