Today, brick pipes for stoves and fireplaces are mounted much less frequently. This is due to the emergence of more reliable products that better cope with the removal of combustion products and are easy to install. One of such products is a sandwich pipe for a fireplace or stove, which consists of several layers and is characterized by high fire safety.

Content

- 1 Sandwich Pipe Features

- 2 Requirements for a pipe sandwich for an oven

- 3 Advantages and disadvantages of sandwich pipes

- 4 Stainless Steel Sandwich Sizes

- 5 Determination of the height of the chimney above the roof

- 6 Structural elements

- 7 Selection tips

- 8 How to do it yourself?

- 9 Preparing for the installation of a chimney from a sandwich pipe

- 10 Installation of sandwich pipes

Sandwich Pipe Features

The chimney is an important part of the heating system, which performs a number of functions. However, the main purpose of this design is the removal of combustion products from heating devices. It is also worth noting that the chimney ensures the safe operation of the entire system.

Sandwich pipes are a very popular solution for arranging a chimney. Such pipes differ in that they prevent the formation of condensate in the winter. The absence of moisture accumulation reduces the amount of soot deposits on the walls of the products. This allows for preventative cleaning less frequently and increases the operational life of the system as a whole.

The design of the sandwich is quite simple: it consists of two pipes, one of which is located in the other. The inner pipe, as a rule, is made of heat-resistant stainless steel, and the outer one is galvanized. The distance between the inner and outer pipes is filled with insulating material. Mineral wool, basalt or ceramic wool, and also vermiculite can act as insulation.

Helpful information! The optimal thickness of the insulating material is selected depending on the purpose and type of the processed fuel.

Sandwich pipe meets all fire safety requirements, therefore such chimneys are indispensable for buildings made of flammable materials.

There is a rule for wooden buildings: the outer pipe must be equipped with thermal insulation to reduce the risk of fire. In addition, it is worth noting that the products with the outer and inner tubes made of stainless steel have the best properties.

Sandwich chimney is used in different systems, which may have the following heating structures:

- ovens;

- fireplaces;

- geysers;

- boilers.

Installation of such pipes requires compliance with building codes and rules, as well as fire safety requirements. Ignoring the norms can lead to a fire and become a threat to the life of the inhabitants of the house, so the installation issue must be approached with all seriousness.

Requirements for a pipe sandwich for an oven

The smoke structure, which carries out the removal of combustion products outside the house, must meet certain requirements: to have high strength characteristics, long service life, as well as good heat resistance.Among other things, the chimney must ensure the effective removal of combustion products from radiators and comply with all modern fire safety rules.

Consider the main criteria by which the quality of such a pipe is determined:

Aerodynamic performance. Depend on several important factors. First of all, this is the shape of the cross section of the pipe. A product with a circular cross section is the best solution and does not interfere with the circulation of air flows, which allows you to maintain good traction in the system. Traction problems are quite common and often due to the fact that the design consisting of sandwich parts is not mounted correctly. For normal traction in the system, it is worth considering the number of horizontal sections, tees, bends, etc. Another important factor that affects the aerodynamic properties of the system is the smoothness of the internal walls.

Easy operation and maintenance. In brick structures, the walls of the inner channel, as a rule, contain hollows and protrusions that impede normal air circulation, and also collect deposits of soot and soot. Therefore, such systems require frequent cleanings. Sandwich structures have smooth inner walls and the operation of such systems is much simpler because they do not accumulate soot layers for short periods of time.

Resistance to corrosion. Chimney corrosion is a common problem that leads to pipe destruction. Combustion products contain aggressive chemical compounds that, together with condensate, destroy the walls of the pipes. The inner channel of the sandwich structure consists of stainless steel, which is resistant to corrosion. In addition, as mentioned above, condensate does not form in such systems. Therefore, if we compare the sandwich design with a brick chimney, then the first, of course, is more reliable.

Important! Experts recommend laying a sandwich chimney in the inner wall of the house. Installation of such a structure is preferably carried out with the output through the roof as close to the ridge as possible.

Such a chimney as a sandwich can be removed without a special pipe not only through the roof, but also through the wall

However, in some cases this is not possible, therefore it is allowed to lay the chimney through the wall, but it must be remembered that such installation is fraught with some difficulties. For example, a pipe located outside the house must be well insulated, protecting it from freezing in the winter. Chimney insulationgoing out will help prevent condensation. The walls of such a channel should be thicker than that of intra-house structures. The same applies to the heat-insulating material located between the two sheets.

Advantages and disadvantages of sandwich pipes

Sandwich pipe for a fireplace, stove and other heating equipment, has advantages and disadvantages.

Consider the main advantages of such products:

- universality of installation. The pipe can be removed through the roof of the house, and through the wall;

- ease of installation. The design of the sandwich product allows you to mount it without much difficulty. No special construction equipment is required for installation. All this allows you to accelerate the laying of communication from such pipes;

- lack of condensate. The chimney sandwich device eliminates the formation of condensate, and also slows the accumulation of soot. If necessary, you can optionally install a special tee, which prevents condensation;

- compactness. To arrange a sandwich system does not require large spaces, which is very convenient;

- safety.Such pipes differ in that they can be installed even in wooden houses and other structures made of this material (for example, baths). A chimney sandwich is safe if all the conditions for installing such a system are met;

- require minimal care. Preventive examinations and cleanings of this design are carried out much less frequently than for chimneys made of other materials;

- reliability. Stainless steel, from which the internal, and sometimes external, pipes are made in a sandwich, is distinguished by excellent anti-corrosion properties, as well as resistance to high temperatures;

- plastic. Today on the construction market you can find any components for such chimney structures. A large selection of components allows you to lay a chimney, enveloping beams, rafters and other obstacles that may occur on the path of the chimney sandwich during installation;

- saving. Sandwich pipes for stoves and fireplaces can reduce not only time but also financial costs. This design does not require a separate foundation;

- long service life. With proper installation, the operational life of a pipe sandwich can reach 15–20 years.

Components for sandwich systems are available in a very wide range, this allows you to create chimneys of various configurations

However, sandwich chimneys have their drawbacks. Consider them:

- Despite the fact that the service life of such a pipe is higher than that of a brick, it is not recommended to use it for more than 10-12 years. After this period, it is advisable to carry out repair work or a complete replacement of the structure.

- if the pipe is operated in conditions of constant temperature jumps, deterioration in leakage performance may occur. It is recommended to check the fastenings of such structural elements of the chimney at least once a year.

- The main disadvantage of such sandwiches is their high price, due to the ease of installation and excellent technical characteristics.

Stainless Steel Sandwich Sizes

When purchasing a sandwich, it is worth paying attention to the indicators of the cross-section of the outlet of the pipe from the boiler. The diameter of the sandwich should be no less than this indicator. This is due to the fact that the pipe is put on the outlet of the pipe and from this point its laying begins.

The cross-sectional indicators of the stainless steel inner pipe can be from 100 to 300 mm. And also it is worth remembering that such parts are produced in segments of 0.5 or 1 m. The wall thickness of such products may be different depending on the purpose of the pipe (0.5 or 1 mm).

Important! The components for the sandwich chimney have certain angles, which are worth paying attention to. Corners have an angle of 90 °, and tees can be of two types: 90 and 135 °.

The thickness of the heat-insulating layer between the inner and outer pipes may vary, however, the most common indicators are 4–6 cm. The dependence of the outer diameter of the sandwiches on the inner is presented in table No. 1.

Table 1

| Du inner pipe mm | Outer pipe mm |

| 300 | 350–400 |

| 250 | 300–350 |

| 200 | 250–300 |

| 180 | 250 |

| 150 | 200–250 |

| 140 | 200 |

| 130 | |

| 120 | |

| 115 | |

| 110 | |

| 100 |

When removing the chimney through the roof, it is worth considering a number of rules associated with this event. The correct location of the chimney ensures a good outlet of combustion products and normal traction in the system.

Determination of the height of the chimney above the roof

When calculating the length of the chimney above the roof, the following rules must be considered:

- chimney height must be at least 5 meters. Such indicators are required for normal traction in a system that provides the removal of combustion products. If the channel length is less than 5 meters, it is necessary to install a special device that will increase traction - an electric smoke exhaust;

- above a flat roof, it is necessary to mount a sandwich pipe so that it rises by at least 0.5 m above the roof material;

- if the distance from the roof ridge to the pipe sandwich is less than 1.5 m, the pipe should be at least 0.5 m above the ridge;

- if the distance from the ridge to the chimney is from 1.5 to 3 m, then the pipe can be mounted at the same level with the upper boundary of the roof;

- if the distance from the ridge to the pipe exceeds 3 m - the height of the structure should be below the level of the upper boundary of the roof with a slope of no more than 10 °;

- when installing a furnace sandwich pipe in a bathhouse, one more important rule must be taken into account: if buildings located above are located nearby the bathhouse, then the pipe is mounted above these objects.

The height of the chimney is calculated depending on the shape of the roof of the building, the proximity of the ridge, as well as the presence of other structures around the house

Structural elements

The main details of such a chimney are straight sections of 0.5 and 1 m in length. However, in addition to this, there are auxiliary parts that are worth paying attention to:

- Horizontal sections. People call such sites "sunbeds". Such parts are connected using revision tees. This is necessary in order to avoid clogging of the structure.

- Tee. A structural element that is mounted at the beginning of the vertical channel and performs the function of eliminating condensate and unwanted blockages in the system. In most cases, tees are installed immediately after the structure exits through the wall. One of the outputs of such a product is made in such a way that it is possible to eliminate the moisture accumulated in it.

- The corner. Such an element is necessary to change the direction of the structure at right angles. Such products are made from the same materials from which the sandwich pipe is made. Insulated with an additional layer of heat insulator.

- Compensator. Sandwich chimney under the influence of high temperatures, as a rule, expands in a linear direction. A compensator is needed to balance the movement of the structure. In multi-storey buildings, such devices are usually mounted on each floor.

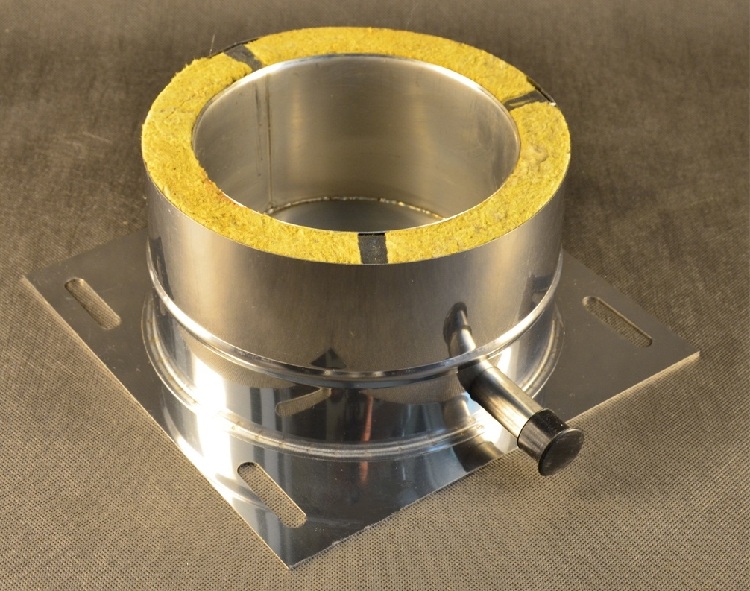

- Passage knot. A design that is mounted in the ceiling and roof and allows the passage of the pipe through these floors. It is a protective box containing thermal insulation material.

- Waterproofing apron. It is installed along the perimeter of the chimney pipe on the roof to protect the roof opening through which the chimney sandwich passes.

- Clamps. Fasteners that provide reliable fixation of the structure to walls and ceilings.

- Protective cap. Element installed on the end of the chimney on the roof. Protects the chimney channel from atmospheric precipitation, as well as debris.

All structural elements of the chimney (elbows, corners, tees and much more) are also equipped with a layer of thermal insulation

Selection tips

Experts recommend that you be careful when choosing a sandwich pipe for the furnace and pay attention to the following points:

- First of all, it is worth checking the quality of the material from which such a product is made. Good material is the key to the fact that the design does not fail during operation;

- The second important point is the density of the insulating material between the two pipes. It is recommended to purchase products with insulation that can withstand at least 700 ° C;

- Do not forget about welds. For furnaces and boilers that generate heat by burning solid fuel, it is recommended to purchase a pipe sandwich with welds made by laser welding. For gas boilers, ordinary rolled seams are also suitable;

- it is very important to remember that the inner tube in the sandwich must be made of stainless steel. Galvanization is suitable only for gas boilers;

- if the chimney is used for a solid fuel furnace, it is desirable that the outer layer be made of stainless steel. However, in this case, galvanized steel is also acceptable, but not copper, brass, etc.

- stainless steel has its own brand. The brand is determined by the technical characteristics of the metal. The most suitable grades for the manufacture of inner pipes in sandwich are 316 Ti, 321 and 310S. Such grades are able to withstand temperatures of 850 ° C, and the latter - more than 1000 ° C.

The temperature values of the combustion products, depending on the type of heating equipment and fuel are shown in table No. 2.

table 2

| heating equipment | Fuel | Smoke temperature ° C |

| Fireplace | Firewood

|

350–650 |

| Bake | ||

| The furnace for a bath | Firewood | 350–700 |

| Boiler

|

Coal | 500–700 |

| Gas | 120–200 | |

| Diesel fuel | 160–250 | |

| Sawdust | 220–240 |

How to do it yourself?

Today it is not difficult to acquire all the necessary materials in order to make a sandwich pipe yourself. Sandwich installation work must be done in stages.

However, before embarking on it, it is necessary to purchase and prepare all the materials necessary for this:

- stainless steel pipe;

- thermal insulation material;

- galvanized iron sheet.

Note! As a heater, you can choose any suitable material. The main rule that should be followed is the appointment of a future design. Based on this, you can determine exactly what temperature will be in the system and choose the appropriate thermal insulation.

The thickness of the insulating layer, as mentioned above, can be from 4 to 6 cm. In addition, it is worth noting that expanded clay or polyurethane can be used as insulation.

After the insulation and other materials are selected, you can proceed directly to the assembly of the structure. First, you need to lay the insulating material on the inner tube of stainless steel. Then you should wrap the resulting workpiece in a sheet of galvanized steel. As a rule, the outer pipe consists of several fragments. It is worth paying special attention to the bonding of individual fragments of the structure. Self-tapping screws are suitable for connecting galvanized iron. The surface of the sheet must be well fixed with them, as well as fasten together individual fragments of galvanization (if any).

The pipe section adjacent to the heater is exposed to high temperatures and may burn out. Therefore, it is recommended to mount this section so that it can be quickly replaced in case of breakage. It is important to remember that unlike purchased products, such pipes are more difficult to install. To assemble the chimney as a designer will not work. Based on this, it is recommended to fasten the entire structure at once.

When laying pipes through the ceiling and roof, you should take care to exclude the risk of fire of the floor material. For this, a special steel box filled with heat-insulating material is mounted at the overlap.

Preparing for the installation of a chimney from a sandwich pipe

Preparation includes the planning of the project, as well as the necessary design calculations. The project of future communication is applied to the paper, thereby determining the best way to lay it. If necessary, you can download the finished project on the network. However, it must be remembered that each case is unique and experts recommend always compiling individual projects.

In addition, it is strictly forbidden to place a sandwich pipe directly above the furnace firebox. For this, it is necessary to install a chimney that will exit the furnace. Such a gutter must be made of heat-resistant material to withstand high temperatures. The sandwich part is attached to this gutter using a special transition element.

After the project is completed, it is necessary to proceed with the calculation of materials and parts. It all depends on which pipes you use - homemade or purchased.The calculation of the finished pipes is quite simple, since they are manufactured according to certain standards, but if you decide to assemble all the elements of the chimney with your own hands, you will have to be patient. The calculation of materials is made for each case individually, however, it is recommended to purchase them with a margin.

Then it is worth doing all the necessary markup. Marking is done for brackets. This is very convenient, since the brackets are located every meter. Proper marking is an important point that will help maintain the verticality of the system. After that, you need to mount the through-nodes (boxes).

Installation of sandwich pipes

Joining the pipes together is quite simple: the inner pipe of the upper part of the chimney is joined with the lower element of the second pipe. Thus, a tight and durable connection is obtained.

Important! Laying the chimney sandwich is always carried out from the bottom up.

Experts recommend applying special sealant to the joints of the sandwich pipes for added reliability. Such a sealant must be resistant to temperatures of at least 100 ° C. In addition, individual parts of the structure are fixed by means of special clamps and brackets.

In almost all cases of installing a chimney from a sandwich pipe, it becomes necessary to turn. There are two ways to rotate:

- rotate the structure by 15, 35 or 45 °;

- 90 °.

The first option is mainly necessary for enveloping obstacles when laying a pipe through the ceiling or roof, and turning at right angles is usually necessary when installing a chimney sandwich through the wall.

The passage through the floors should be in a vertical or horizontal (through the wall) position. Any deviations are not allowed. When laying the chimney through the wall, it must be remembered that the length of the horizontal segment should not exceed 1 m. Otherwise, such a system will have problems with traction, it will be easily clogged and will soon fail.

Among other things, it is necessary to ensure that the communications inside the house do not come in contact with the sandwich construction. This rule applies to all networks: gas pipes, electric cables, etc.