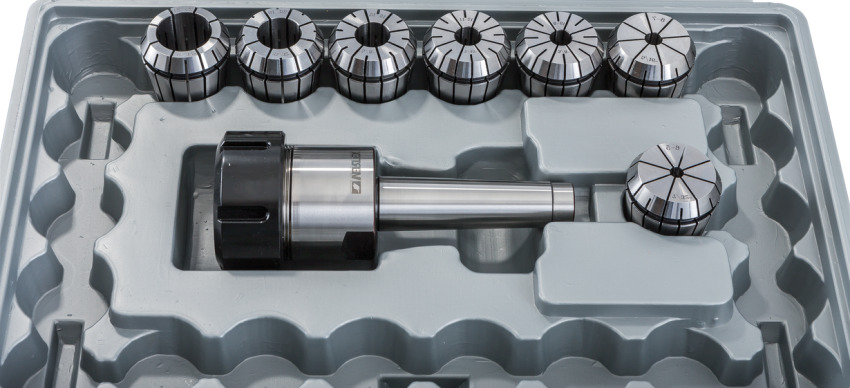

A collet clamp is a device for fixing parts of a cylindrical or prismatic shape. Collets are spring-loaded split bushings with three to six petals, mounted in a special cartridge. They have found application in mechanical engineering, in household and professional tools, and in many other areas of human activity, where it is required to ensure a reliable connection of structural elements.

Content

How are collet chucks arranged?

To make a collet chuck, use hardened tool steel. This ensures high durability of the device, which will have long operation, during which workpieces or tools will be repeatedly fixed and removed.

The design of the collet chuck includes:

- housing;

- collet;

- compression ring;

- lock nut.

The principle of operation of all modifications that differ in size and features of the device is the same: pressure is transferred from the nut for clamping to the conical formation, and through it the formation of radial compressive force directed to the workpiece to be clamped (tool, part).

The collet used gave the name to the most common collet chuck - ER. The advantages of a collet clamp over conventional chucks used in turning (milling) machines are:

- simplification of the installation or removal of the part (workpiece);

- the possibility of reliable fixation of a part having a small diameter;

- the ability to use solid inserts.

ER collet chuck is available with a set of collets for workpieces of different diameters, which are installed depending on the specific size of the shank.

Collet clamp

The use of a collet clamp for pipes can significantly simplify the process of assembling the pipeline and significantly reduce its cost by abandoning the services of third-party specialists.

Three types of this connecting element are distinguished according to its purpose for certain types of structures:

- soft;

- semi-solid;

- solid.

The type of collet clamping for the pipe is selected based on what material was used for its manufacture:

- metal;

- plastic;

- polypropylene, etc.

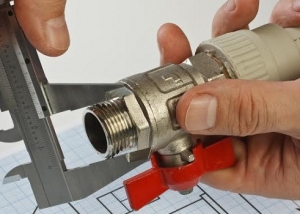

After specifying the diameter of the pipe, you can begin to assemble the structure.

Note! The only limitation is that the straight clamp collet is not accepted to be installed in hard-to-reach places. The reason is this: such structures need periodic inspection and pulling up of weakened elements, so access to them should be simple.

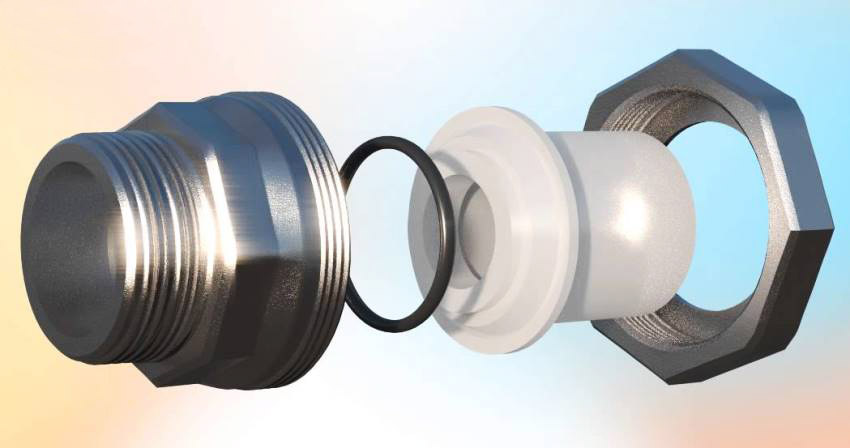

The collapsible design for direct clamping is easy to install. A springy split sleeve presses on the pipe from the inside, a sealing ring is pressed on top with a lock nut. Through the ring, the pressing force is transmitted to the pipe walls, which are tightly clamped on the sleeve.

Varieties of compression and detachable joints

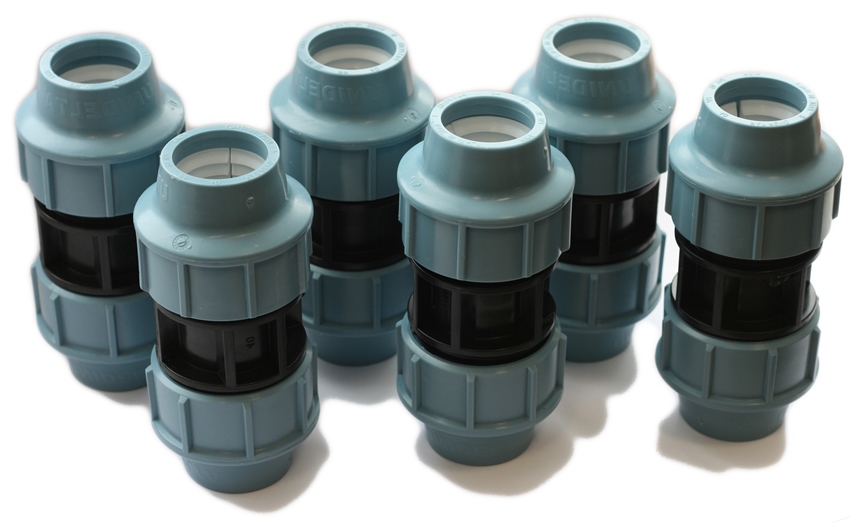

The collet clamp for connection is selected based on the material of the pipe.Copper pipes, as usual, are joined with a copper collet fitting. Soft, ductile metal pressurizes against pressure surfaces. Brass products that withstand operating pressures up to 25 atmospheres and temperatures rising to 115º C are highly appreciated. But such a high-quality product is not recommended for use in pipelines with aggressive environments. In addition, brass is susceptible to corrosion, so its service life is quite limited.

Pipes made of PPRC polypropylene, low pressure polyethylene (HDPE) and cross-linked polyethylene can be connected with plastic collet fittings.

Collets in polypropylene fittings are made of stainless steel. The pressure ring in the grip and the guides in the sleeve are made of polypropylene. To enhance the product, some manufacturers add an external metal ring placed above the internal thread. Pipes from different polymeric materials are docked with such products:

- nylon;

- polyamide;

- polyurethane;

- polyethylene, etc.

Collets are widely used in detachable fittings:

- water outlet;

- Euroconus. For joining exclusively metal-plastic pipes;

- crosspiece;

- adapter;

- tee;

- the corner.

The use of collet joints during installation of the pipeline allows to achieve significant savings in working time and material and financial resources, to extend the life of the system. Crimp connections allow you to:

- to assemble a pipeline with a temperature of the working medium reaching 170º C and a working pressure of up to fifteen atmospheres;

- join pipes with an internal cross section of eight to one hundred millimeters;

- assembly of the pipeline will require a simple set of tools in the form of two adjustable (gas) wrenches or a set of open-end wrenches, which an employee with minimal qualifications will handle;

- installation is extremely simple and quick.

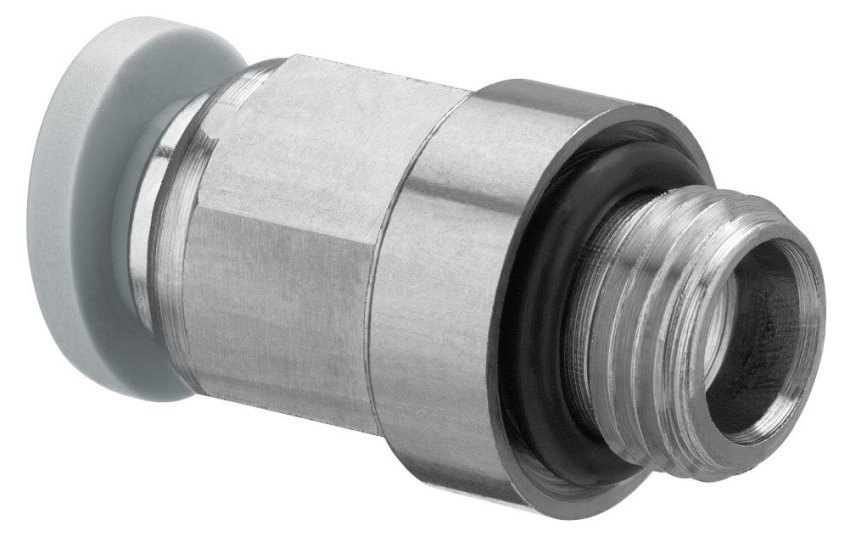

Pneumatic pipe clamps

Pipe fittings can be used to connect pipes in pneumatic systems, that is, those that are pressurized with compressed air. Naturally, a sealed connection can be provided with parts that are capable of operating at this pressure. For the manufacture of clamps for such use are required:

- high-tech plastic based on acetate polymer. Such products are used in air filtration systems. The clamps are resistant to corrosion and have a high degree of rigidity. They find application in conditions when the range of operating temperatures is set at -10º C and up to + 70º C, and the working pressure reaches twelve atmospheres;

- other polymers (polyamide, polyurethane, polyethylene, teflon);

- metals and alloys (brass, copper, steel, stainless alloys).

With pneumatic collet fittings, the piping system can be quickly mounted or disassembled. They are extremely reliable, resistant to high pressure and a wide temperature range.

Important! With all the advantages, these are very specific products that can be installed only in certain working systems and only for certain purposes. Their use in the same pneumatic systems is excluded in order to control the circulating flow of compressed air or gas.

How to mount a metal-plastic water pipe using collet clamps

In everyday life, metal-plastic pipes noticeably squeezed similar products from all other materials. Installation of water pipes using crimp connections has become the most common of all plumbing operations. It is carried out in the following sequence:

- The measured section of the metal-plastic pipe with the help of special scissors or another tool is separated so that the cut is made relative to the axis strictly at a certain angle - 90 °.

- A calibrator is used to straighten the pressed end (restore the cut profile) and chamfer. The resulting chips and debris are removed.

- The straight collet fitting is disassembled immediately from both ends, twisting the lock nut from the threaded end and removing the o-ring from the fitting.

- After disassembling is completed, the nut is first put on the pipe, and then the o-ring. The end around the fitting is lubricated with silicone.

- The pipe is put on the fitting, pressing against the end of the fitting with the highest possible density. The operation requires accuracy so as not to damage the o-rings.

- The connection must be firmly fixed. The required fixation is achieved by moving the o-ring to the end of the crimp connection and tightening the lock nut on the thread. The locknut is screwed in carefully to prevent the o-ring from squeezing out. The first turns are made without the use of tools. The wrench is used for pre-immobilized fitting until the moment when characteristic creaking is heard. With these sounds, the wrench is set aside so as not to spoil a sufficiently fragile lock nut.

Avoiding damage to the sealing rings and locknuts, it is possible to achieve tightness of the crimp connection. Its disassembly is also not difficult.

Benefits of using a collet chuck

Collet connections should not be used only in those places where it is impossible to inspect and tighten in a timely manner. But the clamp does not weaken so quickly, you have to scroll to avoid leakage no more often than once a year. In all other cases, the use of crimp connections is associated exclusively with the achievement of significant advantages. It is customary to relate to them:

- the possibility of repeated use. The use of a collet clamp allows you to freely replace the damaged section of the water supply or pneumatic pipe, carry out repair work;

- long exploitation period, equal to decades;

- wide range and availability. It is not difficult to pick up a collet tightening with the necessary characteristics from practically any producer either in a specialized supermarket (usual or working through the Internet), or in the construction market;

- reliability and tightness of the assembly;

- ease of installation, which does not require special skills and a complex set of professional tools;

- relatively low costs for the purchase and installation;

- superior performance.

The use of a clamping collet is recommended, justifying close to the perfect combination of its advantages with a relatively low cost and minimal overhead associated with installation and subsequent operation.

Collet clamps make many connections in various branches of economic activity. The rationality of their device allows with a high degree of reliability to fix the necessary parts, blanks, tools and structural elements. At the same time, for the most part, there is no need for either a special tool or training skills.

A wide selection in terms of the use of materials for manufacturing, design features and technical characteristics led to a high level of demand for products. The demand for crimp connections with the use of collets also contributes to their low cost and extremely low costs of material and financial resources during installation.A simple and convenient design satisfies almost all the requirements that can be advanced to the connecting element.