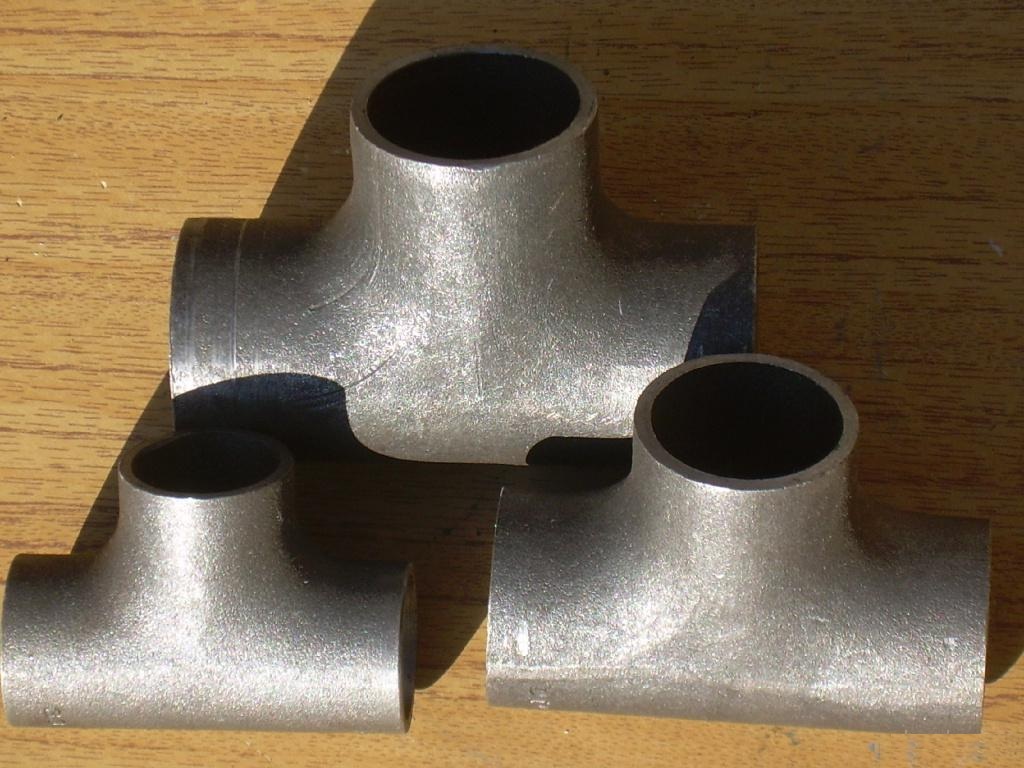

A tee is a product that relates to connecting elements (fittings) and is used in the installation of various pipeline structures. The function of the tee is the branching of the flow of the working medium, by attaching to the main branch. To date, these steel fittings are most often used in laying gas and oil pipelines, and in other industries.

Content

Operational areas, design and production technology

Today, steel products can be used in pipeline structures that transport various working environments. Consider the main substances that travel through such communications:

- water;

- steam;

- gas;

- petroleum products.

Consider the structural elements that make up this part:

- welded product;

- three nozzles.

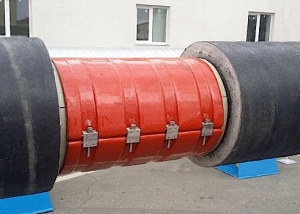

Note! Pipes, as a rule, are coated with special heat-insulating material to protect the tee in severe climatic conditions.

There are several ways in which this part can be completed:

- hot stamping;

- water stamping;

- welded method.

The most common way to manufacture these products is by stamping from a single sheet. This is due to the fact that such a method requires a minimum of financial costs. It is advisable to use hot stamping for mass production of these connecting devices.

These connectors are regulated by state standards (GOST). Steel tees are described in GOST 17376. Such parts are made of carbon or alloy steel, and are used when laying industrial-type communications. There are products that are regulated by another regulatory document - GOST 17376-2001. Such steel fixtures are made of carbon and low alloy steel.

The operational areas of this type of steel connecting products do not end on industrial pipelines. They are used for other designs:

- heating piping systems;

- water pipes;

- gas pipelines.

Using a tee, you can easily connect to the trunk line, so this product is so popular and is used in almost all industries. The most widely used fixture today is a welded product. And for pipes with large cross-sectional indicators, flange tees are used.

Varieties of Steel Tees

All steel connecting parts of this type are divided into two main types, depending on the parameters of the branch pipe section:

- equal bore (straight);

- transitional (flange).

The first variety is used for joining pipes with the same cross-sectional indicators. And transition tees are used in cases where it is necessary to connect two pipes with different cross-sectional indicators.

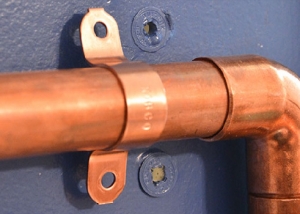

According to the connection option, two main varieties of these devices are distinguished:

- welded model;

- threaded model.

Welded and threaded products carry out the connection between the main line and auxiliary branches. In the first case, the pipe joint is performed using welding equipment, and in the second, using thread.

Steel tees are made of corrosion-resistant materials (for example, stainless steel) or have a protective anticorrosive layer, which is applied to the surface during production. A special enamel can act as a protective layer.

Flange devices are divided according to their design into the following types:

- flat welded;

- welded collar flange;

- loose on the weld ring.

All of the above types are regulated by various GOSTs. GOST 12820–80 describes flat welded steel tees. And GOST 12821–80 and 12822–80 govern two other types of these devices.

Main characteristics

All steel tees differ in their characteristics: cross-sectional indicators, length, joining method, mass, etc. A wide range of characteristics can significantly expand the operational sphere of these products.

Stamp-welded connecting fittings of this type are manufactured in accordance with the technical specifications and are able to withstand pressure indicators up to 25 atmospheres. The temperature range of such parts ranges from −30 to +300 ° C. The characteristics of steel tees are presented in table 1.

Table 1

| Mm | External indicator of section, mm | Product weight, kg |

| 1000 | 1016 | — |

| 800 | 813 | — |

| 600 | 610 | — |

| 500 | 508 | — |

| 400 | 406,4 | 88–131 |

| 300 | 323,9 | 47–77 |

| 250 | 273 | 33–52 |

| 200 | 219,1 | 16–44 |

| 150 | 168,3 | 9,4–24 |

| 100 | 114,3 | 3,8–10 |

| 80 | 88,9 | 2,2–6,2 |

| 50 | 60,3 | 1,6–3 |

| 32 | 42,4 | 0,79–1,5 |

| 25 | 33,7 | 0,25–0,8 |

| 20 | 26,9 | 0,26–0,46 |

| 15 | 21,3 | 0,19–0,38 |

Stainless steel has good resistance to corrosion, therefore, products from it are so popular when laying drinking water utilities. Stainless steel tees are used in pipeline structures, the pressure indicators of which reach 16 MPa. The temperature range for such devices ranges from −70 to +450 ° C.

Helpful information! The most frequently used products in the food industry are tees made of stainless steel.

Seamless steel parts, as a rule, are used when laying industrial water pipes transporting gas and oil products. According to GOST, tees can have different weights. The mass of steel tees depends on their diameter and ranges from 190 g to 131 kg. The cross-sectional indicators of such parts can be from 15 to 1000 mm.

Steel tees are indispensable connecting devices used for branching auxiliary branches in various pipeline structures. Such parts are characterized by high strength, anti-corrosion properties, as well as reliability and durability (subject to all installation rules).