Adapters for pipes are connecting elements made of different materials that are used for joining pipes in pipeline structures for various purposes. The operational area of these products extends to almost all pipe communications, including: water pipes, heat pipes, gas pipelines, sewer systems, smoke and ventilation pipes.

In piping systems, it is often necessary to join pipes of different diameters, in such cases adapters of appropriate sizes are used

Content

Features of transition elements

First of all, all transition elements for pipelines are divided into two main types:

- concentric;

- eccentric.

The first group includes fittings that are used for communications located in a vertical plane, and eccentric parts are used for joining pipes in horizontal structures. Both of these groups are actively exploited for economic and industrial purposes.

Consider the main materials from which the transitions are made:

- steel;

- cast iron;

- brass;

- polypropylene (PP);

- polyvinyl chloride (PVC);

- polyethylene (PE).

For the manufacture of steel transition elements, as a rule, various types of steel are used:

- stainless;

- galvanized;

- carbon

- alloyed;

- high alloyed.

Note! Carbon steel fittings are used in pipeline structures transporting slightly aggressive and medium aggressive working environments. In turn, products from alloyed and high alloy steel are used in more severe conditions.

Every year, plastic fittings are more and more distributed, displacing steel products. This is due to the fact that they have light weight, corrosion resistance, as well as a more affordable cost.

Adapters for plastic pipes

Adapters for metal-plastic pipes are mainly used in such pipeline structures:

- water pipes;

- heating systems.

All connecting elements for metal-plastic communications are divided according to the installation method into three main groups. Consider them:

- compression products;

- threaded devices;

- press fittings.

The first group of fittings includes products that are mounted by soldering. Compression adapters are used for pipes of different diameters, as well as for the organization of conventional joints. They are made of various materials and can be: metal, metal-plastic and plastic.

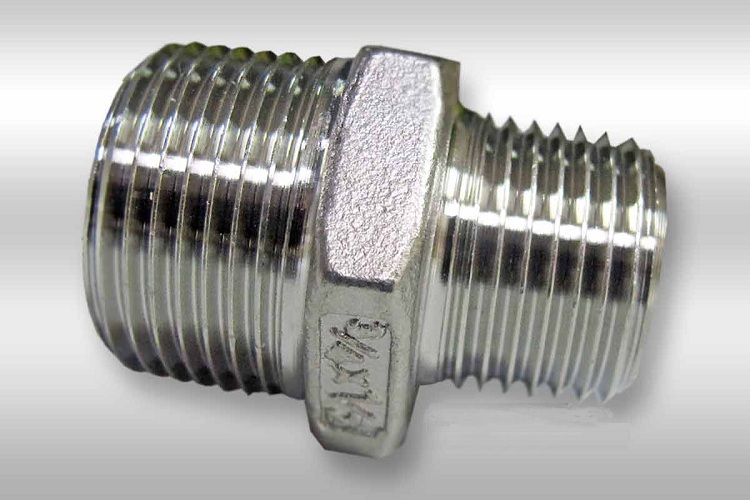

The threaded adapter for plastic pipes joins them through the thread. Such a connection is called detachable, since, if necessary, the connecting node can be disassembled without much difficulty. Threaded adapters are the most expensive and are used, as a rule, in cases where it is necessary to organize the transition from plastic to metal pipe (for example, docking with a heating radiator).

Consider the main disadvantages of threaded transition elements that are used to connect pipes made of metal:

- poor tightness, which requires the use of various sealants (flax thread, FUM tape, etc.);

- the need for ongoing preventive checks;

- low speed of installation of communication.

Press models belong to a specialized group of fittings and are used to organize one-piece assemblies in pipeline structures. Installation of such models is carried out using special equipment, namely: a press machine. Such a machine is intended for heating the fitting and pipe, which contributes to the formation of an integral compound made at the molecular level. Transition elements may vary in design. Consider the most common options for such fittings:

- couplings;

- tees;

- corners;

- transitions.

Transitions are devices that facilitate the formation of joints between pipes, which have different cross-sectional indicators. The main advantage of press fittings is that they are able to provide high joint tightness.

Adapters for various plastic pipes

Polymer adapters are the most common group today. The range of these products is incredibly wide and diverse, so they are used in almost all pipeline structures. Consider the basic materials from which plastic pipe transitions are made:

- Polypropylene (PP). Transition elements from this material are used not only in pipelines transporting cold water, but also in hot water systems. This is due to the fact that the maximum working temperature of polypropylene junctions can reach +120 ° C. Polypropylene is characterized by high strength characteristics, is resistant to harmful corrosive effects. Polypropylene products are resistant to aggressive chemicals, have smooth inner walls that create minimal resistance to the flow of the working medium. The maximum cross section for transitions from PP is 400 mm.

- Polyethylene (PE). Such transition elements are very common and are used to organize joints in the overhead or trench installation of pipe communications. They, like polypropylene fittings, have anti-corrosion properties and have smooth inner walls. The maximum cross section of PE products does not exceed 400 mm.

- Polyvinyl chloride (PVC). Models made of polyvinyl chloride are used in pipeline structures, the pressure of which does not exceed 16 atmospheres. PVC fittings can be used both in pressureless and pressure communications. PVC adapter can be used for joining pipes of different diameters.

Note! As a rule, PVC transitions are used to connect pipes in sewer systems, so their diameters are suitable for sewer pipe standards (50 and 100 mm).

Composite Such products are made of polymeric materials and have metal inclusions (bushings). Thanks to metal bushings, with the help of such products it is possible to organize transitions not only between pipes with different cross-sectional indicators, but also to different materials. The cross-sectional index for the polymer segment of the composite transition does not exceed 400 mm, and for a metal sleeve reaches 60 mm.

The connection of plastic pipes can also be done using metal transition elements.Fittings of various metals are installed on polymer pipes, the diameter of which does not exceed 60 mm. Conventional metal transitions are used for various pipelines (including drinking ones), and structural ones only for gas transmission communications and technical lines.

Adapters for sewer pipes

Sewer communications, like any others, are mounted using transition elements. Laying sewer lines often requires the organization of joints between pipes made of different materials (for example, cast iron and plastic). For these purposes, a special rubber cuff is used, which is able to provide two transition options:

- interior;

- outer.

In the first case, the rubber cuff is inserted into the connecting socket of the cast-iron pipe, as a result of which it becomes possible to install a polymer pipe. Such a joint does not need additional sealing, so there is no need to apply special sealants. In the case of an external passage or, as it is also called, a bottle, pipes are connected without connecting the cuff to the socket.

Consider the two main groups of fittings that are used when laying sewer networks:

- for internal sewerage;

- for external sewage.

All fittings are classified according to the connection option to:

- Welded. Such transition elements are mounted using special welding equipment. Welded products are not equipped with rubber seals and threads.

- Glued. They are joined with pipes by means of special adhesive compounds. Like welded models, glued fittings are not equipped with threads and gaskets.

- Threaded. They are equipped with thread and in most cases are used for joining small pipes.

- Rubber ring. A popular variety of transition elements used during the installation of various sewer structures. The main advantage of these products is that they form very tight joints.

Smoke and ventilation ducts are often made of stainless steel and their adapters are also resistant to corrosion

Adapters for ventilation pipes and chimney

Adapters for the chimney, as a rule, are used if it is necessary to perform a quick docking of pipes with different cross-sectional indicators. However, they are also used to join pipes from different materials (for example, stainless steel and brick). Adapters for chimney pipes contribute to the connection of chimney channels of various shapes.

Helpful information! Such details are most common when organizing the transition between the rectangular outlet of the heat generator and the chimney, which has a circular cross-sectional shape.

Chimney adapters consist of two main structural elements:

- upper;

- lower.

The upper part of the adapter is standardized for pipes, and the lower is made in the form of a truncated pyramid. Thus, the lower part is intended for docking with rectangular surfaces. The upper part of the chimney adapter is joined to the bottom by welding.

The adapter for the ventilation pipe or adapter is used to organize transitions between ventilation pipes with different cross-sectional indicators or different shapes.

Consider the factors classified ventilation transition elements:

- production material;

- option for connecting to the duct;

- dimensions of the inlet.

Adapters are installed at the outputs of exhaust communications. In addition to its main function, ventilation adapters also perform auxiliary ones: eliminating air turbulence in the system, reducing the speed of transportation of air masses, etc.

As a rule, ventilation adapters are made of stainless steel, which is characterized by corrosion resistance and high strength. To increase the corrosion resistance, stainless steel can be subjected to additional zinc treatment. The cross-sectional index of ventilation passages can vary from 125 to 250 mm, however, if necessary, products of non-standard sizes can be ordered from manufacturers.