When laying pipelines for various purposes, they branch, rotate, deepen and join. To perform the installation, steel bends are used, prepared and made for a specific version of the pipe routing. They, like the pipes themselves, are insulated with a special insulating layer - polyurethane foam (PPU). PPU branch allows you to constructively change the direction of the pipeline in the desired direction. Welding into the track special bends prepared for various angular joints changes its design. These blanks allow you to technologically and quickly perform work on laying the pipeline, in accordance with the intended design goals.

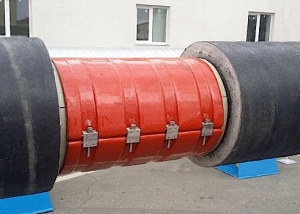

Bends in polyurethane foam insulation are necessary to change the direction of the pipeline collected from insulated pipes

Content

PPU as an insulator of steel pipes and structures

The use of a highly effective hydro and heat insulator of polyurethane foam is highly functional and justified by the practice of application. Its thermal conductivity is the smallest known. This material is not subject to intense burning. Its density is in the range of 30 - 60 kg / m³. Due to its waterproofing properties, it is widely used in construction.

It is applied to the surface or to the volume by the formation of foam. Foam instantly expands, fills the required area or volume, thus creating the insulation barrier that is needed. The foam layer contains about 95% of the void, and 5% is a kind of basis for the solid frame of the insulating form, where the hardness itself depends on the quality of the material itself, as well as on the experience of the operator creating the insulating layer.

The use of this excellent insulator for coating steel pipes, in particular their bends, is very effective in terms of installation functionality, operational reliability of the coating and its durability. PPU has a number of qualities and properties:

- the durability of the use of the material, its service life is determined from 20 to 35 years;

- low weight, which does not burden the structure, but rather creates a certain rigidity;

- resistance to decay, to the influence of microorganisms, allows its use in residential premises;

- does not support combustion, can be used in structures subject to certain flammability;

- PPU - pure material from the point of view of environmental pollution, can come into contact with food equipment;

- high-quality heat insulator, has the properties of noise absorption and water resistance.

Polyurethane foam insulation performs its functions for a long time even underground, since it is not susceptible to decay and corrosion.

Note! Based on the above properties, pipelines and bends in polyurethane foam insulation are a standard and quite familiar solution to modern technologies.

Reliability, durability, functionality of the application distinguishes PPU insulation from other materials with thermal insulating and protective properties.

Types of PPU branches

The bends in the PU foam insulation are bent or welded pipe sections at a specific design angle with an inner diameter comparable to the geometric dimensions of the pipeline itself.By design, bends are made of polymers, steel, galvanized metal, stainless steel, combined products. Basically, the design angles of the branches are 30, 45, 60, 90 degrees. Bends-adapters are manufactured: when it is necessary to realize a transition from one pipe diameter to another.

Bends are critical elements of a pipeline system. They have the following operational properties:

- mechanical resistance;

- ultimate pressure in the system - up to 2.6 MPa;

- possess anticorrosive properties;

- resistant to temperature effects, from - 60 ° to + 150 ° C;

- durability, service life up to 30 years.

Taps in isolation PPU are made according to the requirements of GOST 30732-2006. Many deliver bends according to customer specifications. Typically, these products are made from pipes with a diameter of 57 mm to 1220 mm.

Properties and quality characteristics of bends

Bends are made from the same material as the main pipeline. The high-quality composition of the external insulation and the internal working pipe has a common construction with the pipeline. The tap itself only redirects the laying of the main thread in the right direction, bypassing obstacles and changing the depth of the trace. The challenge is to connect the main directions of the pipeline. The joints are insulated with special mounting insulation kits.

The design of the branch includes the following components:

- steel main pipe;

- polyurethane foam insulating layer;

- central support;

- steel branch;

- electrical insulating tube for steel-coated pipes;

- polyethylene coating;

- cable for operational remote control (UEC), if necessary.

Features of the use of bends in insulation foam

The scope of taps in PPU is quite extensive:

- production and transportation of oil, gas and derivative liquids and technical compositions;

- metallurgy, where pipelines for various purposes carry out the pumping of gases, water and other components of the technological process;

- petrochemistry and technological processes for the creation of technical fluids, their transportation;

- energy and utilities, heating pipelines, hot and cold water pipelines.

For ground and underground laying, bends are made with a different coating:

- on the surface - with galvanized coating;

- for underground installation - in a polyethylene sheath.

Important! The specifics of pipeline welding may require bends with different lengths of pipes, with the required angles and with different installation diameters at the inlet and outlet. Taps are often used to separate fluid flows. Their manufacture has its own specifics in terms of diameters and the installation process of products.

The bends in the PU foam insulation are technological installation elements, without which it is impossible to correctly and accurately trace any pipeline. Modern PPU insulation provides such products with a long service life and operational reliability.