Installing plugs on profile pipes is the final, but important part of the construction of the fence on the site. This stage is necessary for the preservation of the metal profile pipe. Protected by a plug, the pipe will not deteriorate from constant contact with moisture. In addition, silencing elements can be useful in the construction of furniture, the installation of decorative and functional parts in the interior. Installation of such fittings will not be difficult even for those who do not have significant experience in repair work.

Content

Why are plugs for a profile pipe needed?

End caps are small, simple in their construction, but very significant fittings. They help isolate the cavity of the profile pipe from ingress of debris and, most importantly, precipitation. Profile products are used in the construction of fences from corrugated board or mesh netting. If the intake stands remain unprotected, liquid and condensate accumulate very quickly, and due to constant stagnation of moisture, the metal walls become unusable in a fairly short time. Damaged fence racks cannot guarantee the strength of the entire structure, and a profile pipe insulated by a plug becomes as durable as a solid metal bar.

In addition to damping parts, parapets and intake caps are also used to protect profile pipes from the negative effects of atmospheric factors. They can have a different shape (even forged nozzles are produced) and quite successfully cope with the decorative function.

Pipes that are part of a street structure must be plugged to prevent water from accumulating in them.

Types of plugs for profile pipe

The fundamental point in the classification of these shaped elements is the material from which the plug was made. In the manufacture of these parts, the following materials may be involved:

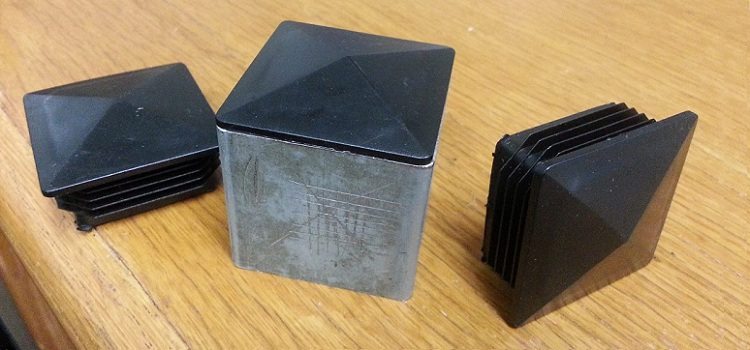

- Different types of metals. Reliable and high-quality fittings, most often aluminum, steel or brass are taken for their manufacture. As a rule, they are equipped with threads - with their help durable collapsible joints are obtained. Due to the good strength characteristics, steel and brass damping parts have become popular in the field of gas pipelines and water supply services. Metal plugs are also available for profile pipes, but they are used only in cases where aesthetic and operational properties are very important. Metal plugs with a square cross section are especially in demand in the furniture industry.

- Chrome metal. This material makes expensive fittings that are not susceptible to corrosion. As in the previous case, the use of damping elements made of chrome steel is relevant only in special conditions.

- Polyethylene and other polymers. Cheaper, but quite good coping with their duties fittings. They completely prevent water from entering the pipe, do not deteriorate from constant interaction with moisture.Plastic plugs can not lose their original shape for a long time: they are not afraid of even temperature fluctuations.

Important! At the same time, the plastic plug on the profile pipe should be made of a material that is well tolerated by ultraviolet radiation. For example, HDPE (low-pressure polyethylene) is destroyed by sunlight.

- Rubber. Rubber fittings are used only as a temporary plug designed to protect the pipeline from debris and dust entering. Rubber fittings are not suitable for profile pipes, but they will also be able to find their application on the home site, for example, as a cork for seasonal closing of the irrigation system.

One of the most economical solutions is a homemade plug for profiles. It is a metal plate of the required diameter, welded to the walls of the pipe. Of course, when organizing isolated sections of a water supply or sewer system, this method should not be used.

Design features of caps for pipes

The types of constructions of shaped parts for insulation also differ. In total, four main varieties of designs can be distinguished:

- Thread plugs. Such parts are put on the pipe using threaded threads on the fitting and on the profile itself. Shaped threaded parts are most often found in metal, but some manufacturers also produce plastic threaded parts. Only suitable for round profiles.

- Pneumatic elements. They are fixed in the pipe using a pump. When air is pumped into the fitting, it increases in size, and its shape completely coincides with the cavity of the pipe.

- Elliptical details. Such plugs are made only of metal, for their installation you need a welding machine. Their main purpose is permanent fixation on the sewer pipe, but their installation is also possible on supporting pillars of circular cross section.

- Flange elements. Metal or rubber fittings, mounted with bolts or rivets. To make the connection, holes are provided located around the perimeter of the fitting.

For profile pipes, only end caps are suitable, which are either inserted into the pipe or put on top like a cap

In addition to these varieties, transportation plugs are also available that are designed to preserve the quality of the pipes during transport. Another type of parts - end caps - are made primarily of rubber or flexible plastic for temporary use.

Characteristics of plugs for profile pipes

Technical characteristics of shaped elements depend on the material of manufacture and design features:

- metal - withstand heating to a temperature of + 500-600 degrees, without changing its structure. Corroded, which can significantly reduce their operational life. To avoid rust on such fittings, they must be coated with a special primer or paint;

- chrome plated - practical "not killed" parts, but as long as the layer of chrome plating remains intact. With constant mechanical impact on the chrome-plated fitting, the protective coating is erased, and, in fact, remains a part made of simple steel, also subject to corrosion;

- plastic - these elements cannot boast the ability to withstand the same temperatures as metal, but in most cases this factor is not necessary. Plastic plugs for profile pipes have a guaranteed operational period of 7-10 years, but in the absence of serious negative factors, they can continue to be used for much longer.

End caps also come in an external or internal configuration.For shaped pipes, square plastic fittings are only available externally. And more flexible PVC plugs can also be used as an internal part.

Metal plugs may have a more aesthetic appearance than plastic, but their service life is short due to corrosion

Rules for installing silenced fittings

The principle of mounting the external plugs is very simple. For good sealing of plastic plugs for profile pipes, the following rules should be observed:

- If a threaded fitting is installed, a sealing material should be used to improve the strength of this connection. Best of all, FUM tape manages this function.

- Threaded gaskets are used to seal non-threaded fittings.

- If a metal plug is installed, then in the case of profile pipes, it makes sense to make a welded joint. In a situation where the profiles will be reused and the plug is no longer needed, it will have to be cut off along with a small portion of the pipe.

For the installation of plastic fittings no special tools are required - all the work can be done manually. If the pipeline from the profile is operated in difficult conditions, then more durable plugs are used. They can be made of metal plastic, some shaped elements are even reinforced.

Installing and removing plugs for profile structures that perform only the supporting function does not require special safety measures. While shutting off gas, water and sewer systems, it is necessary to stop the flow of medium passing through the pipeline.

Choosing a fitting for the support pillars of the fence, it is a reasonable decision to stop at the plastic plugs for the profile pipe. They cope well with both protective and decorative function. On sale you can even find monophonic shaped elements with a figured surface: they are spherical, pyramidal, square, and also made in the form of a lens. Plugs are available for all sizes of profile pipes.