A crimp coupling is nothing more than a fitting designed to connect pipeless pipe ends to each other if welding is impossible or undesirable. In addition, such an element is used in cases where pipelines are subject to frequent assembly / disassembly during operation. A crimp sleeve is also often used to seal the steel pipes.

Content

Types of Crimp Fittings

Such connections of pipeline elements are of two types:

- crimp. They are equipped with one or two rings. The principle of operation of parts of this type is based on the use of a polymer seal. Under the influence of external pressure, this material is compressed, tightly covering the outer surface of the inserted pipe. The result is a tight connection.

- press. With their help, an integral connection is created. The disadvantage of press fittings is the inability to reuse in the event of a leak. Then it will just be necessary to replace it.

A steel pipe crimp coupling does not have this drawback. Such fittings are made of various materials, but the following advantages are inherent in all of them:

- wear resistance and durability;

- large selection of different configurations.

The main disadvantage of the compression sleeve on the steel pipe is the relatively small reliability of the connection. In order to reduce the likelihood of depressurization of the joint, the fastening of this part must be periodically tightened.

The main scope of crimp fittings are repair or construction work related to the connection of metal pipes whose outer diameter does not exceed 60 millimeters. The design of this part consists of a body (base) and fittings equipped with crimp rings and union nuts, with the help of which a reliable fastening is performed. Quick assembly / disassembly - this is the main advantage that is characteristic of these removable products. After all, if there is a need to dismantle the pipe, you will not have to cut the weld.

Advice! To replace an adapter of this type, you can use not only a similar model, but also another fitting with identical characteristics.

Convenient and inexpensive crimp couplings for connecting steel pipes are practically devoid of flaws, and if leaks occur during operation, this will most likely be caused by poor-quality work of the contractor.

Application

Crimp type connections are used for mounting cold and hot water supply systems, heating systems, underfloor heating, for transporting water for household needs, for example, for irrigation.

On the market you can find the following types of crimp fittings designed to connect the components of steel pipelines:

- valves

- crosses;

- tees angular (three-dimensional)

- tees with transitions;

- tees are simple;

- corner with transitions;

- angular;

- transitions from diameter to diameter;

- stubs;

- direct couplings.

Crimp couplings also connect sewer pipes made of polyvinyl chloride (PVC), however, such fittings should not be confused, since they have significant differences.

Installation of crimp couplings for steel pipes

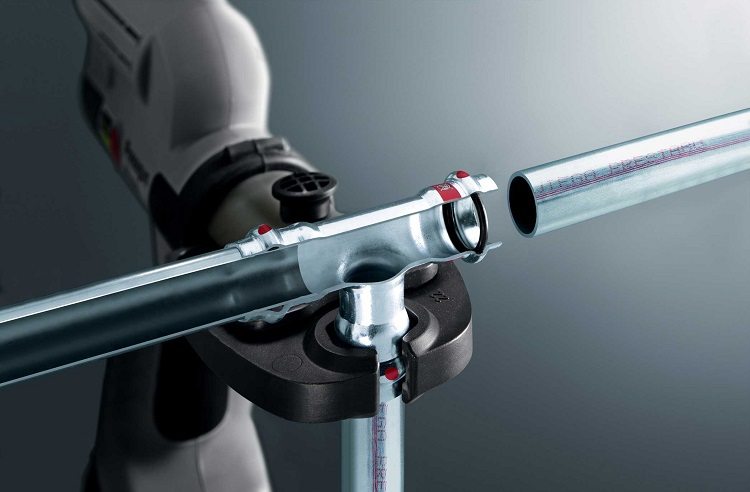

To correctly install these details, you will have to perform the following steps:

- Trim the pipe and deburr the cut, both externally and internally.

- Put the crimping nut on the resulting segment.

- Then pull the crimp ring onto the pipe.

Insert the pipe into the body of the fitting, then tighten the nut on the body. Moving along the thread, it will press the crimp ring into the pipe so that a tight connection results. When tightening, do not use excessive force, let alone leverage. The nut may transfer the connection or burst.

The disadvantages of this connection include low mechanical strength. Strong vibration or shock may cause leakage. But after all, steel pipelines are just mounted to ensure maximum reliability of the water supply system! Indeed, a clear contradiction. In addition, the rubber sealant present in the compression sleeve for steel pipes completely eliminates such a demanded quality as heat resistance.

When choosing a crimp coupling, pay attention to the maximum pressure of the working medium in the pipeline, which will not damage the connection. The table below will help you sort this out. It presents the averaged data when connecting seamless cold-worked steel pipes using a coupling with a steel clamping nut.

The unit of pressure is bars. We remind you: 1 bar ≈ 1 atm ≈ 0.1 MPa .. Pmax - maximum pressure.

Table 1

| Pipe burst pressure | Pmax pipes | Pmax couplings at periodic surges | Permanent Pmax Couplings |

| 240 | 70 | 40 | 70 |

| 290 | 90 | 60 | 90 |

| 340 | 110 | 70 | 100 |

| 400 | 130 | 85 | 120 |

| 460 | 155 | 110 | 140 |

| 490 | 165 | 115 | 150 |

| 530 | 180 | 125 | 160 |

| 616 | 210 | 145 | 200 |

| 740 | 250 | 185 | 240 |

| 920 | 320 | 225 | 310 |

| 1230 | 420 | 290 | 400 |

| 1400 | 490 | 370 | 470 |

| 1850 | 580 | 460 | 550 |

Important! Since crimp joints are collapsible, it is not allowed to install this type of coupling in monolithic cement or concrete screeds.

Often there is a need to reconstruct a steel pipeline. Then, to prevent the early emergence of corrosion as new pipes, it is recommended to use products made from modern materials, for example, from polypropylene. In order to prevent leaks, in this case it is recommended to connect the pipes using fittings made of steel, since polypropylene has a higher linear thermal expansion coefficient.

Features of Crimp Couplings

Crimp couplings are used primarily for connecting pipe elements with the same diameter. Even if it is mounted by welding, the presence of such parts at the ends is mandatory: without them, connecting to other existing branches of the system will simply be impossible. But it is especially advisable to use crimp couplings for steel pipes in industry. After all, they are able to work in a very wide temperature range: -50 ≤ T ≤ + 250˚C.

An important factor is the fastening of a steel pipeline, some of whose elements are connected using crimp couplings. Indeed, from severity during operation, it can bend, which will lead to leaks. Therefore, we dwell on this issue in more detail.

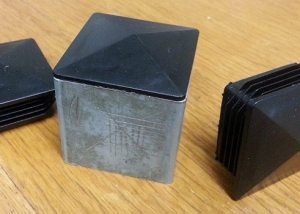

Fastening steel pipes connected by crimp couplings

U-shaped bolts, clamps, clamps, as well as bilateral and single mounting brackets must be used as fasteners. Clamps are plastic and metal. So, in our case, preference should be given to steel galvanized clamps, since plastic products are not able to provide high reliability of the design.

If the pipeline is laid in an open way, you can use both clamps and brackets.Fastening to various supporting structures, walls, columns and horizontal surfaces is carried out not only with the help of these elements, but also with the help of brackets, suspensions and overlays.

So that the pipes connected by crimp couplings, when using clamps, remain coaxial, the distance between the attachment points should be as follows:

- with a diameter of 100 millimeters - 6 meters;

- with a diameter of 40 ≤ D ≤ 80 millimeters - from 3.5 to 4 meters;

- with a diameter of 25 ≤ D ≤ 32 mm - 3 meters;

- with a diameter of 15 ≤ D ≤ 20 millimeters - 2.5 meters;

- for pipes with a diameter of 8 ≤ D ≤ 14 millimeters on a vertical surface - from 1 to 1.5 meters, and on a horizontal - 0.75 meters.

The piping must be marked before installation.

Clamps should be purchased with a small margin in order to make an additional attachment point if necessary.

Important! When bends are attached, the distance from the clamp to the corner should be on the order of 150-200 millimeters.

Competition forces manufacturers to engage not only in improving the operational characteristics of their products, but also in improving their consumer properties. And since after the purchase the fittings will need to be installed, the ease of installation sometimes comes to the fore.

In this context, today the most popular are crimp couplings manufactured by the German concern "Gebo-Armaturen GmbH". For steel pipes, parts with a diameter of 1/2 to 2 inches are available. They withstand water pressure of 10, and gas - 4 bar, and will become assistants to both amateurs and professionals working with steel pipelines.